4

Operating Your Tiller

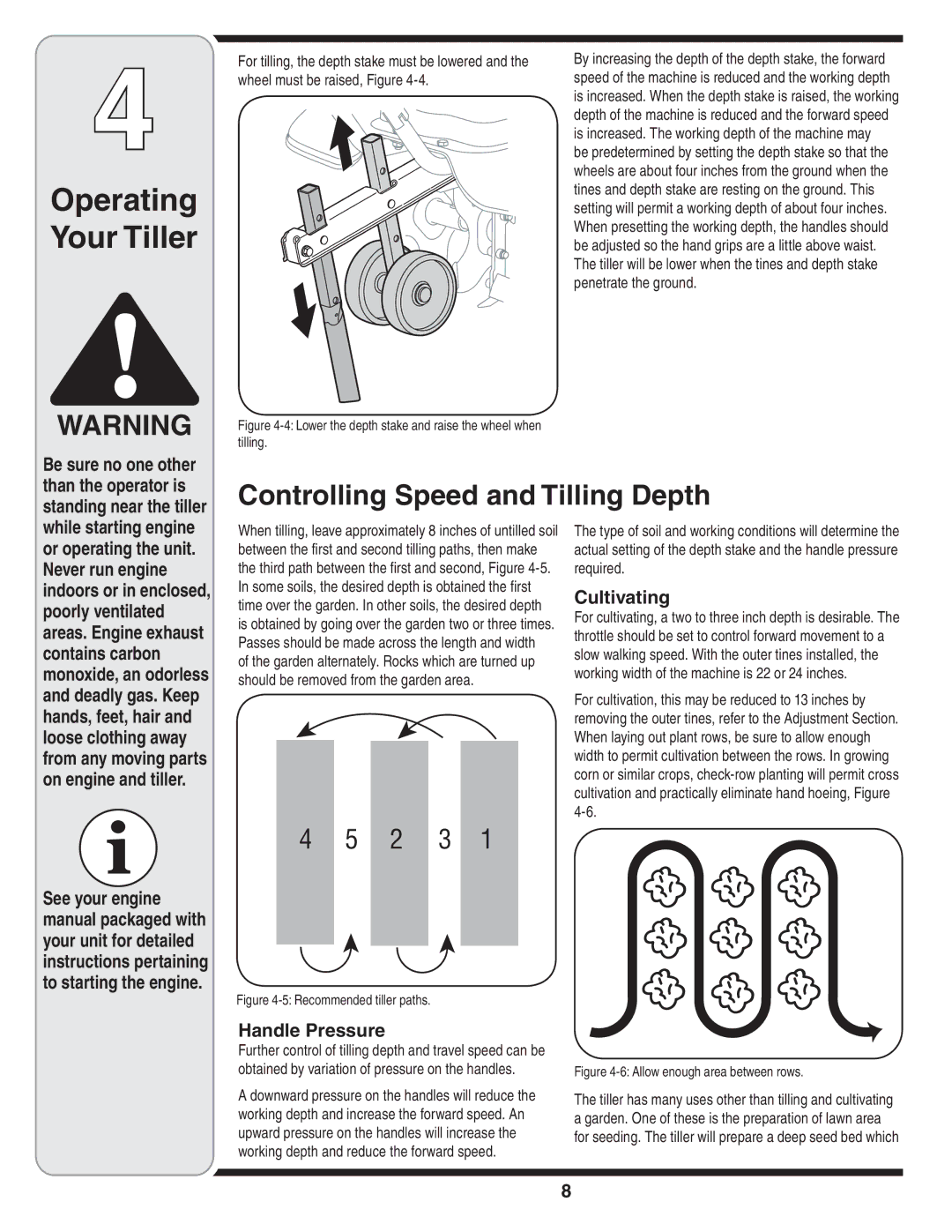

For tilling, the depth stake must be lowered and the wheel must be raised, Figure

By increasing the depth of the depth stake, the forward speed of the machine is reduced and the working depth is increased. When the depth stake is raised, the working depth of the machine is reduced and the forward speed is increased. The working depth of the machine may

be predetermined by setting the depth stake so that the wheels are about four inches from the ground when the tines and depth stake are resting on the ground. This setting will permit a working depth of about four inches. When presetting the working depth, the handles should be adjusted so the hand grips are a little above waist. The tiller will be lower when the tines and depth stake penetrate the ground.

WARNING

Be sure no one other than the operator is standing near the tiller

Figure 4-4: Lower the depth stake and raise the wheel when tilling.

Controlling Speed and Tilling Depth

while starting engine or operating the unit. Never run engine indoors or in enclosed, poorly ventilated areas. Engine exhaust contains carbon monoxide, an odorless and deadly gas. Keep hands, feet, hair and loose clothing away from any moving parts on engine and tiller.

When tilling, leave approximately 8 inches of untilled soil between the first and second tilling paths, then make the third path between the first and second, Figure

of the garden alternately. Rocks which are turned up should be removed from the garden area.

The type of soil and working conditions will determine the actual setting of the depth stake and the handle pressure required.

Cultivating

For cultivating, a two to three inch depth is desirable. The throttle should be set to control forward movement to a slow walking speed. With the outer tines installed, the working width of the machine is 22 or 24 inches.

For cultivation, this may be reduced to 13 inches by removing the outer tines, refer to the Adjustment Section. When laying out plant rows, be sure to allow enough width to permit cultivation between the rows. In growing corn or similar crops,

See your engine manual packaged with your unit for detailed instructions pertaining to starting the engine.

4 5 2 3 1

Figure 4-5: Recommended tiller paths.

Handle Pressure

Further control of tilling depth and travel speed can be obtained by variation of pressure on the handles.

A downward pressure on the handles will reduce the working depth and increase the forward speed. An upward pressure on the handles will increase the working depth and reduce the forward speed.

Figure 4-6: Allow enough area between rows.

The tiller has many uses other than tilling and cultivating a garden. One of these is the preparation of lawn area for seeding. The tiller will prepare a deep seed bed which

8