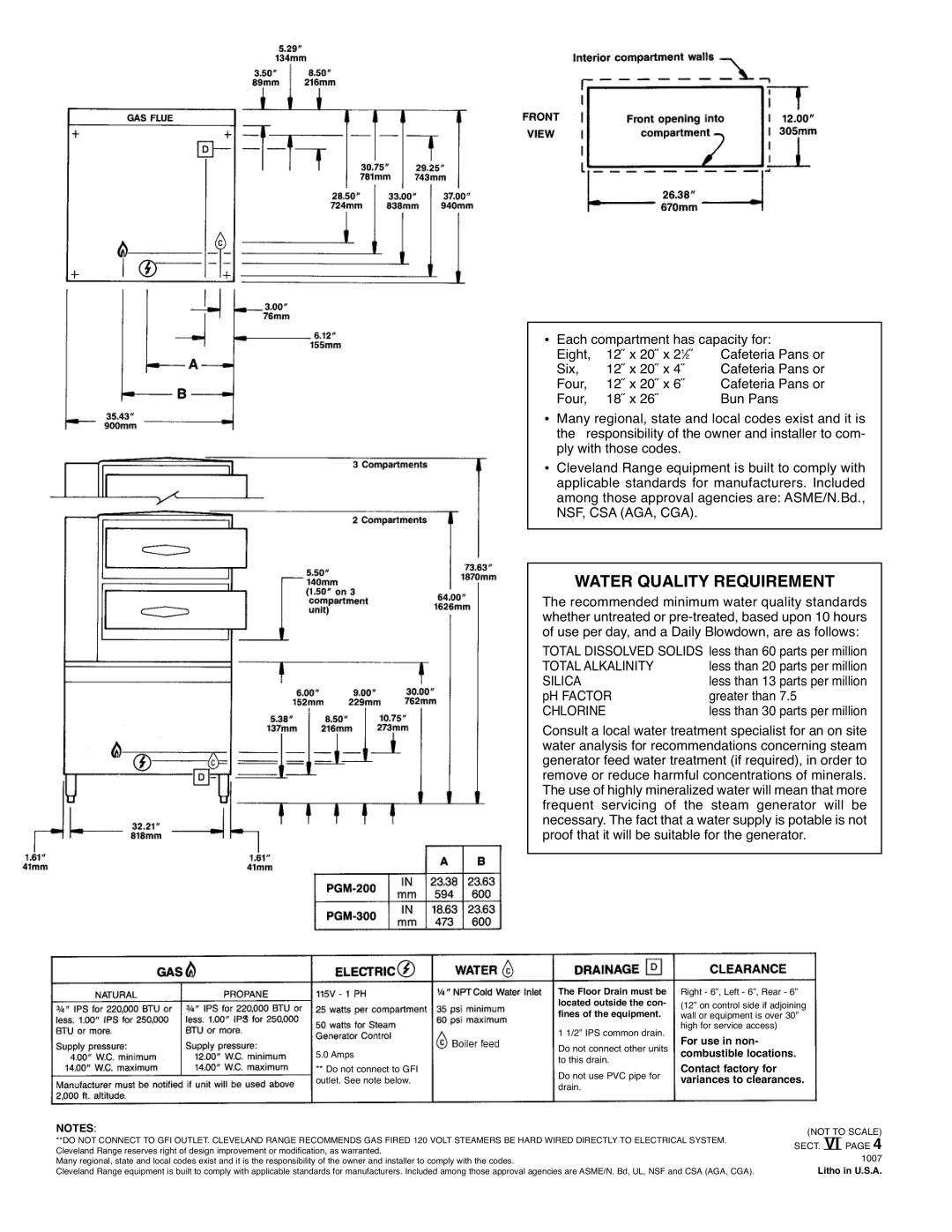

PGM-200-3, PGM-300-2, PGM-200-2, PGM-300-3 specifications

Cleveland Range has established itself as a prominent player in the commercial kitchen equipment arena, specifically with its line of steamers designed for efficiency and performance. The Cleveland Range PGM-300-3, PGM-200-2, PGM-300-2, and PGM-200-3 models exemplify the brand's commitment to quality, ensuring they meet the diverse needs of foodservice operations.The PGM-300-3 is a 300-gallon steam generator steamer, showcasing robust construction and advanced technology. One of its standout features is its three-compartment design, which allows for maximum production capacity while maintaining energy efficiency. The PGM-300-3 is equipped with Cleveland's unique SmartSteam technology. This innovative feature automatically adjusts the steam output based on the cooking process, ensuring consistent results without unnecessary energy consumption. Its high-efficiency burner system also reduces operation costs, making it an environmentally friendly option for kitchens focused on sustainability.

The PGM-200-2, on the other hand, is tailored for operations needing a more compact solution without sacrificing performance. This 200-gallon model offers two compartments, perfect for preparing various dishes simultaneously. Its user-friendly digital controls help staff navigate cooking cycles smoothly, enhancing workflow efficiency. The PGM-200-2 is also built with a durable stainless steel exterior, ensuring longevity in even the busiest kitchens.

Similarly, the PGM-300-2 caters to those requiring a larger steam capacity without overwhelming their space. With its two-compartment setup, this model balances space and cooking capabilities effectively. Like its peers, it employs the advanced SmartSteam technology, offering reliable operation in a diverse range of cooking applications.

Finally, the PGM-200-3 model stands out for its capability to provide three compartments of cooking space. This versatility allows operators to prepare larger quantities, making it ideal for establishments with high-volume demands. Each compartment can be operated independently, which means various foods can be cooked simultaneously, further optimizing kitchen efficiency.

Collectively, these models are designed with safety features such as automatic shut-off, easy-clean surfaces, and water level monitoring systems. Cleveland Range steamers are known for their reliability, energy efficiency, and ease of use, making them the ideal choice for restaurants, schools, and other institutions where food quality and operational efficiency are paramount. Their combination of advanced technologies and practical design continues to set the standard in commercial cooking equipment.