Maintenance

2.Wait until the unit cools before checking the hydraulic oil.

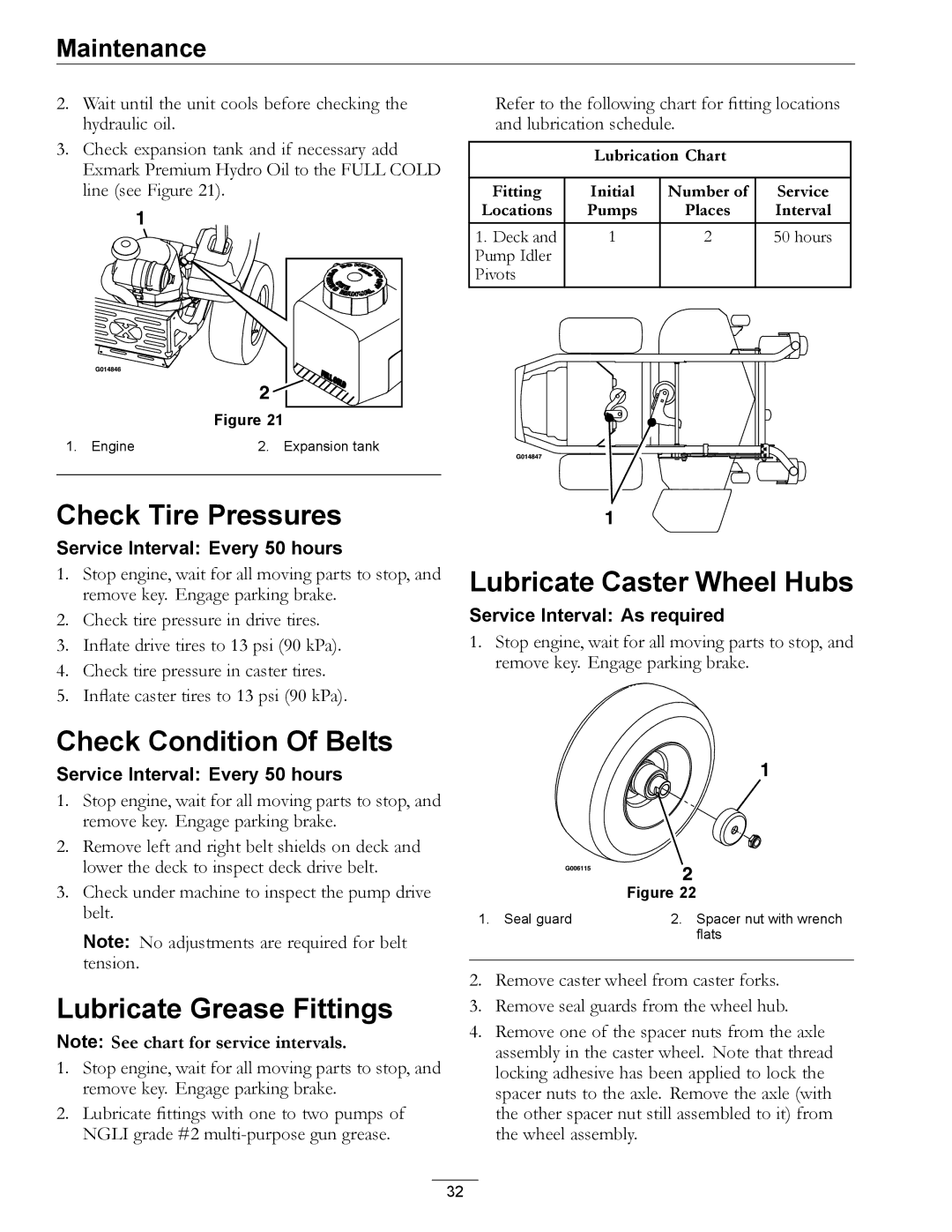

3.Check expansion tank and if necessary add Exmark Premium Hydro Oil to the FULL COLD line (see Figure 21).

Refer to the following chart for fitting locations and lubrication schedule.

Lubrication Chart

Fitting |

|

| Initial | Number of |

|

|

| Service | |||||||||||||

Locations |

| Pumps | Places |

|

|

| Interval | ||||||||||||||

1. Deck and | 1 |

|

| 2 |

|

|

|

|

| 50 hours | |||||||||||

Pump Idler |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Pivots |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 21

1. Engine | 2. Expansion tank |

|

|

Check Tire Pressures

Service Interval: Every 50 hours

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Check tire pressure in drive tires.

3.Inflate drive tires to 13 psi (90 kPa).

4.Check tire pressure in caster tires.

5.Inflate caster tires to 13 psi (90 kPa).

Check Condition Of Belts

Service Interval: Every 50 hours

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Remove left and right belt shields on deck and lower the deck to inspect deck drive belt.

3.Check under machine to inspect the pump drive belt.

Note: No adjustments are required for belt tension.

Lubricate Grease Fittings

Note: See chart for service intervals.

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Lubricate fittings with one to two pumps of NGLI grade #2

Lubricate Caster Wheel Hubs

Service Interval: As required

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

| Figure 22 |

1. Seal guard | 2. Spacer nut with wrench |

| flats |

2.Remove caster wheel from caster forks.

3.Remove seal guards from the wheel hub.

4.Remove one of the spacer nuts from the axle assembly in the caster wheel. Note that thread locking adhesive has been applied to lock the spacer nuts to the axle. Remove the axle (with the other spacer nut still assembled to it) from the wheel assembly.

32