IOD200, IOD150 specifications

Ice-O-Matic has long been recognized as a leading manufacturer of ice machines, and the IOD150 and IOD200 models exemplify the company's commitment to quality, efficiency, and innovation in ice production. Designed to cater to a variety of commercial needs, these machines are engineered to be reliable and effective, making them an excellent choice for restaurants, bars, hotels, and convenience stores.One of the standout features of both the IOD150 and IOD200 is their advanced ice production capabilities. The IOD150 can produce up to 152 pounds of ice per day, while the IOD200 increases that capacity to an impressive 202 pounds. This high-output performance ensures that businesses can meet their ice needs even during peak hours, providing customers with consistently chilled beverages and food items.

Both models are equipped with a built-in storage bin that offers ample space for ice storage. The IOD150 features a 70-pound storage capacity, while the IOD200's bin can hold up to 90 pounds of ice. This built-in storage design eliminates the need for separate ice bins, saving valuable floor space in busy commercial environments.

The design of the IOD150 and IOD200 models incorporates a user-friendly interface, making operation straightforward and efficient. The intelligent control systems monitor ice production and detect any maintenance needs, ensuring optimal performance and extending the lifespan of the machines. This feature is particularly beneficial for busy staff members who may not have specialized training in equipment management.

Energy efficiency is a critical consideration for businesses today, and Ice-O-Matic’s models do not disappoint. Both the IOD150 and IOD200 are designed to operate with low energy consumption, making them cost-effective choices for any enterprise. Their environmentally friendly operation aligns with the growing demand for sustainable practices in the food service industry.

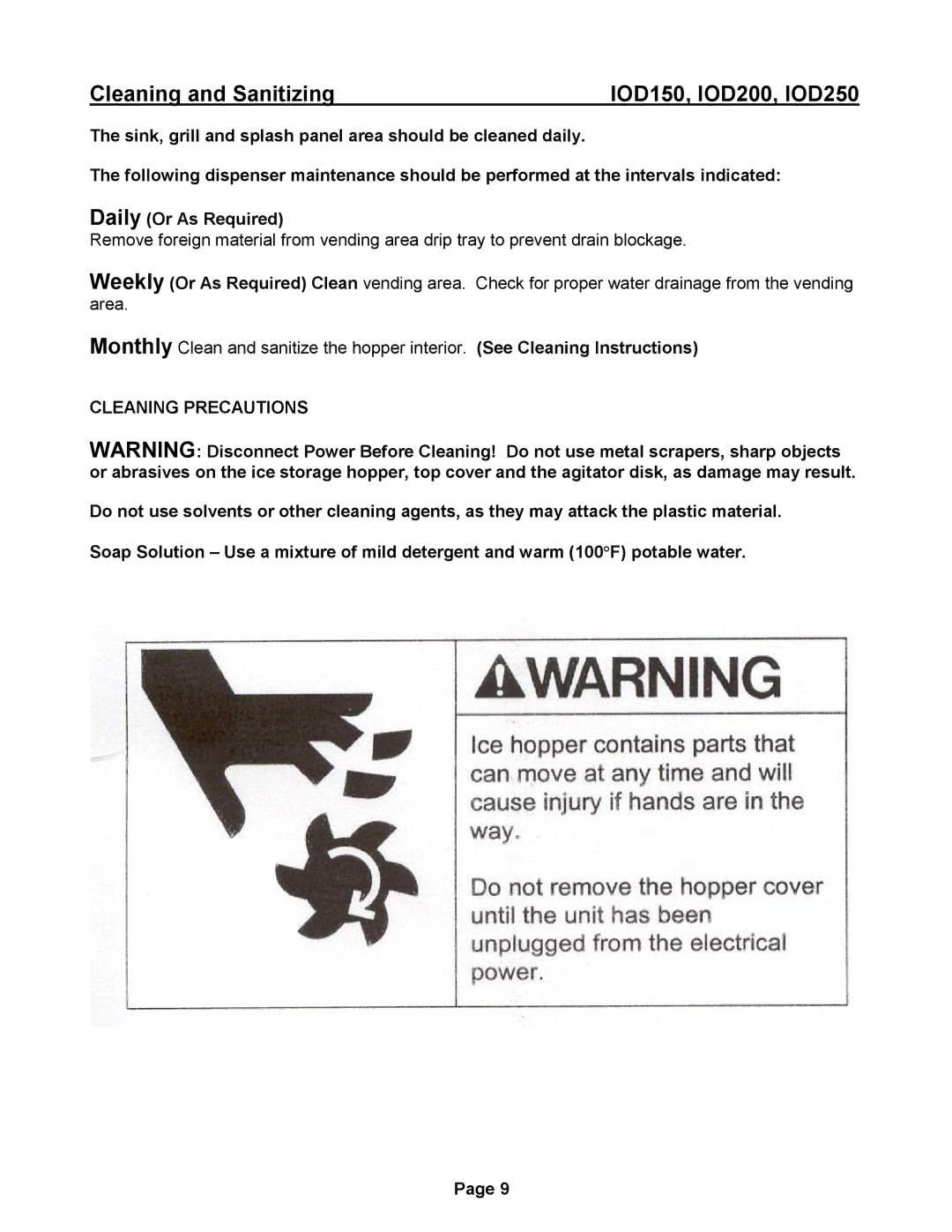

In addition to performance and efficiency, hygiene and cleanliness are paramount in ice production. Ice-O-Matic has integrated a sanitation design in both models, which includes anti-microbial materials. This helps maintain the highest standards of cleanliness, minimizing the risk of contamination.

The IOD150 and IOD200 models represent Ice-O-Matic’s dedication to providing high-quality ice solutions that meet the diverse demands of commercial operations. With their robust features, advanced technology, and focus on efficiency, these machines stand out as top choices for any business seeking reliable ice generation.