TOC

TOC

OPERATION

PULSE WELDING

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

Pulse welding procedures are set by controlling an overall “arc length” variable. When pulse welding, the arc voltage is highly dependent upon the waveform. The peak current, background current, rise time, fall time and pulse frequency all affect the voltage. The exact voltage for a given wire feed speed can only be predicted when all the pulsing waveform parameters are known. Using a preset voltage becomes impracti- cal, and instead the arc length is set by adjusting “trim.”

Trim adjusts the arc length and ranges from 0.50 to 1.50, with a nominal value of 1.00. Trim values greater than 1.00 increase the arc length, while values less than 1.00 decrease the arc length.

Most pulse welding programs are synergic. As the wire feed speed is adjusted, the Power Wave will automati- cally recalculate the waveform parameters to maintain similar arc properties.

The Power Wave utilizes “adaptive control” to compen- sate for changes in electrical

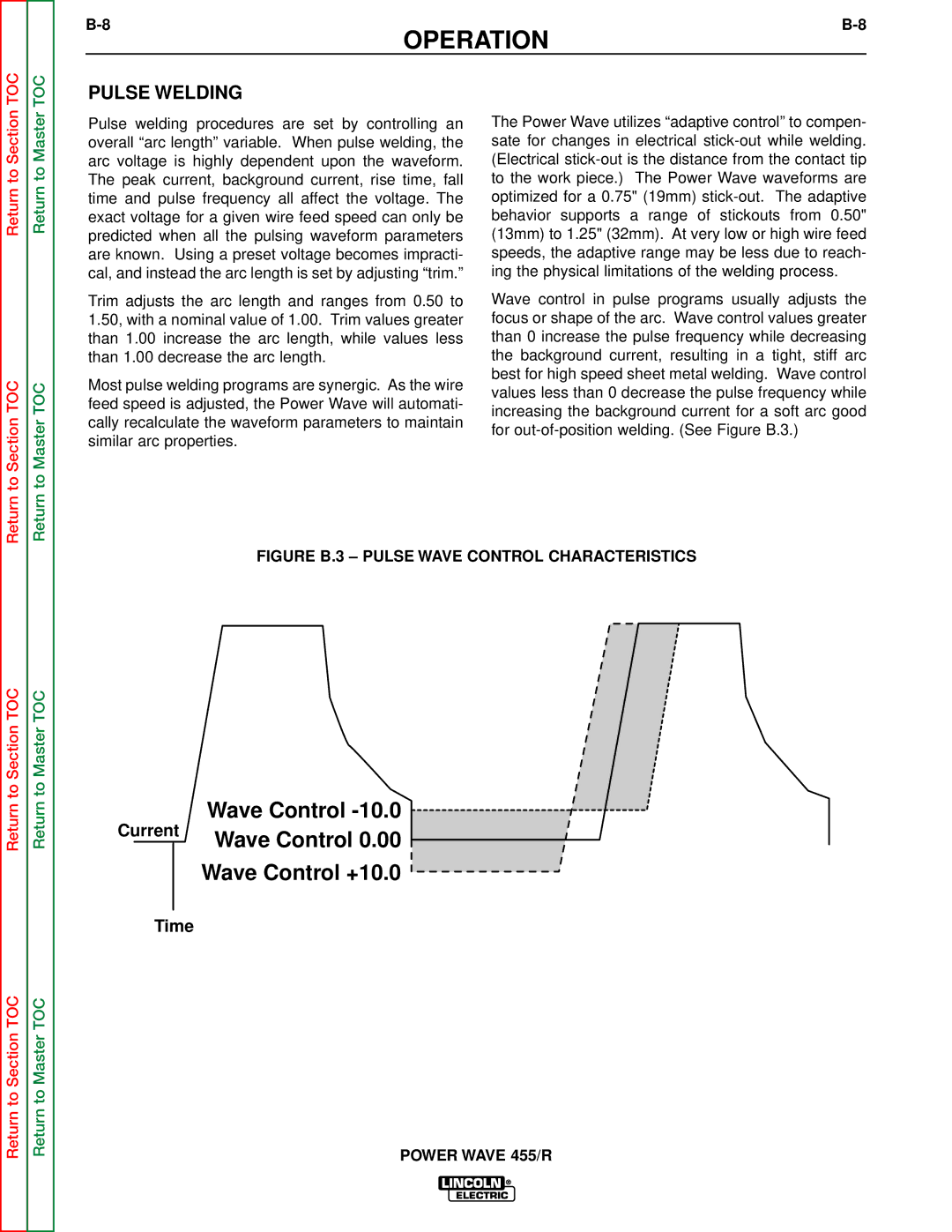

Wave control in pulse programs usually adjusts the focus or shape of the arc. Wave control values greater than 0 increase the pulse frequency while decreasing the background current, resulting in a tight, stiff arc best for high speed sheet metal welding. Wave control values less than 0 decrease the pulse frequency while increasing the background current for a soft arc good for

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

FIGURE B.3 – PULSE WAVE CONTROL CHARACTERISTICS

Wave Control

Current | Wave Control 0.00 | |

|

| |

|

| Wave Control +10.0 |

|

|

|

Time