Model SB1263 | I N S T R U C T I O N S | Mfg. Since 9/11 |

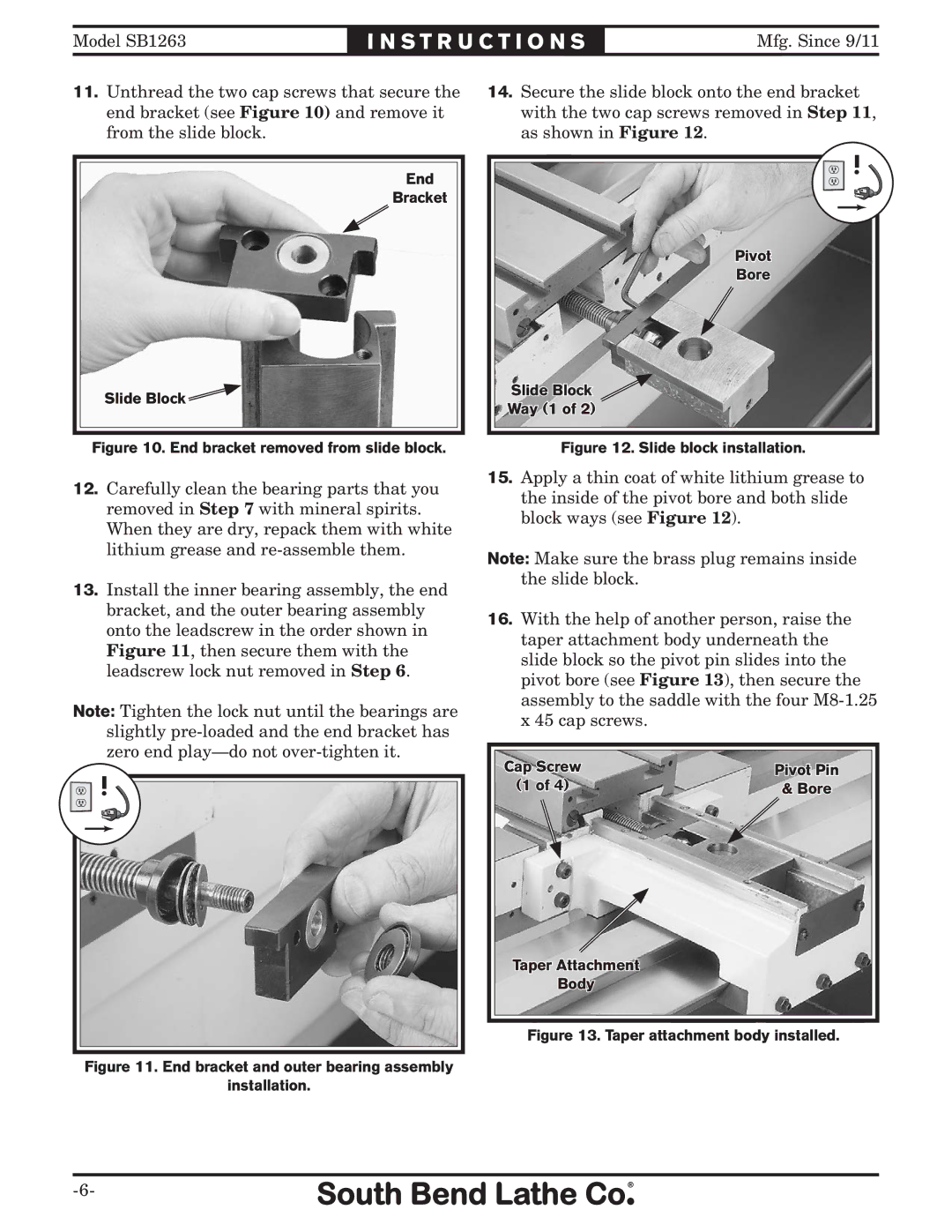

11.Unthread the two cap screws that secure the end bracket (see Figure 10) and remove it from the slide block.

End

Bracket

Slide Block ![]()

Figure 10. End bracket removed from slide block.

12.Carefully clean the bearing parts that you removed in Step 7 with mineral spirits. When they are dry, repack them with white lithium grease and

13.Install the inner bearing assembly, the end bracket, and the outer bearing assembly onto the leadscrew in the order shown in Figure 11, then secure them with the leadscrew lock nut removed in Step 6.

Note: Tighten the lock nut until the bearings are slightly

!

Figure 11. End bracket and outer bearing assembly

installation.

14.Secure the slide block onto the end bracket with the two cap screws removed in Step 11, as shown in Figure 12.

!

Pivot

Bore

Slide Block ![]()

Way (1 of 2)

Figure 12. Slide block installation.

15.Apply a thin coat of white lithium grease to the inside of the pivot bore and both slide block ways (see Figure 12).

Note: Make sure the brass plug remains inside the slide block.

16.With the help of another person, raise the taper attachment body underneath the slide block so the pivot pin slides into the pivot bore (see Figure 13), then secure the assembly to the saddle with the four

Cap Screw | Pivot Pin |

(1 of 4) | & Bore |

Taper Attachment

Body