Inner Adpater Pipe | |

| |

3/8” Phil- |

|

lips Screws |

|

ST649

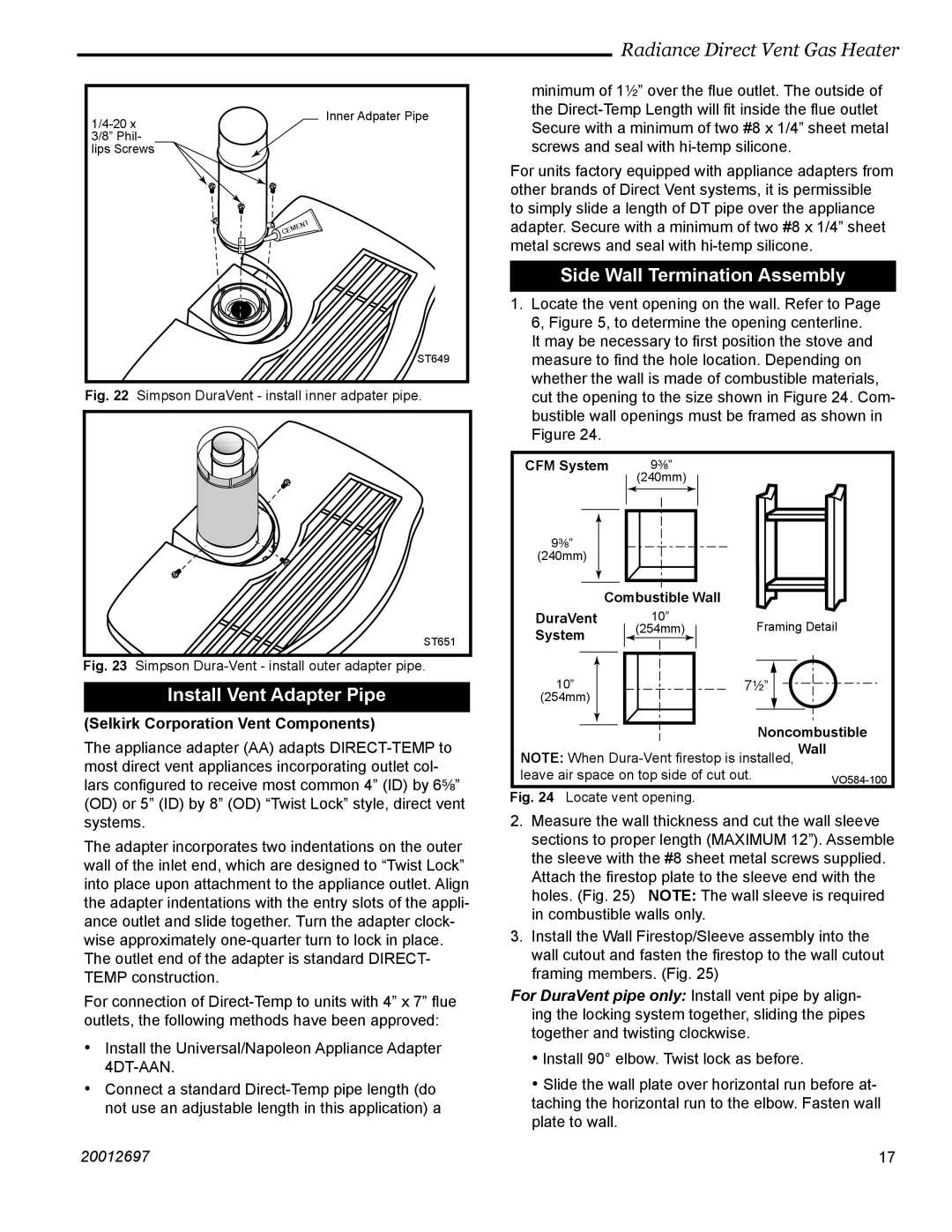

Fig. 22 Simpson DuraVent - install inner adpater pipe.

ST651

Fig. 23 Simpson Dura-Vent - install outer adapter pipe.

Install Vent Adapter Pipe

(Selkirk Corporation Vent Components)

The appliance adapter (AA) adapts

The adapter incorporates two indentations on the outer wall of the inlet end, which are designed to “Twist Lock” into place upon attachment to the appliance outlet. Align the adapter indentations with the entry slots of the appli- ance outlet and slide together. Turn the adapter clock- wise approximately

For connection of

•Install the Universal/Napoleon Appliance Adapter

•Connect a standard

Radiance Direct Vent Gas Heater

minimum of 1¹⁄₂” over the flue outlet. The outside of the

For units factory equipped with appliance adapters from other brands of Direct Vent systems, it is permissible to simply slide a length of DT pipe over the appliance adapter. Secure with a minimum of two #8 x 1/4” sheet metal screws and seal with

Side Wall Termination Assembly

1.Locate the vent opening on the wall. Refer to Page 6, Figure 5, to determine the opening centerline.

It may be necessary to first position the stove and measure to find the hole location. Depending on whether the wall is made of combustible materials, cut the opening to the size shown in Figure 24. Com- bustible wall openings must be framed as shown in Figure 24.

CFM System | 9³⁄₈” |

|

| (240mm) |

|

9³⁄₈” |

|

|

(240mm) |

|

|

Combustible Wall |

| |

DuraVent | 10” | Framing Detail |

System | (254mm) | |

|

| |

10” |

| 7¹⁄₂” |

(254mm) |

|

|

Noncombustible

NOTE: When

Fig. 24 Locate vent opening.

2.Measure the wall thickness and cut the wall sleeve sections to proper length (MAXIMUM 12”). Assemble the sleeve with the #8 sheet metal screws supplied. Attach the firestop plate to the sleeve end with the holes. (Fig. 25) NOTE: The wall sleeve is required in combustible walls only.

3.Install the Wall Firestop/Sleeve assembly into the wall cutout and fasten the firestop to the wall cutout framing members. (Fig. 25)

For DuraVent pipe only: Install vent pipe by align- ing the locking system together, sliding the pipes together and twisting clockwise.

•Install 90° elbow. Twist lock as before.

•Slide the wall plate over horizontal run before at- taching the horizontal run to the elbow. Fasten wall plate to wall.

20012697 | 17 |