M381 301603 OpM (Supplemental) NFPA Hood

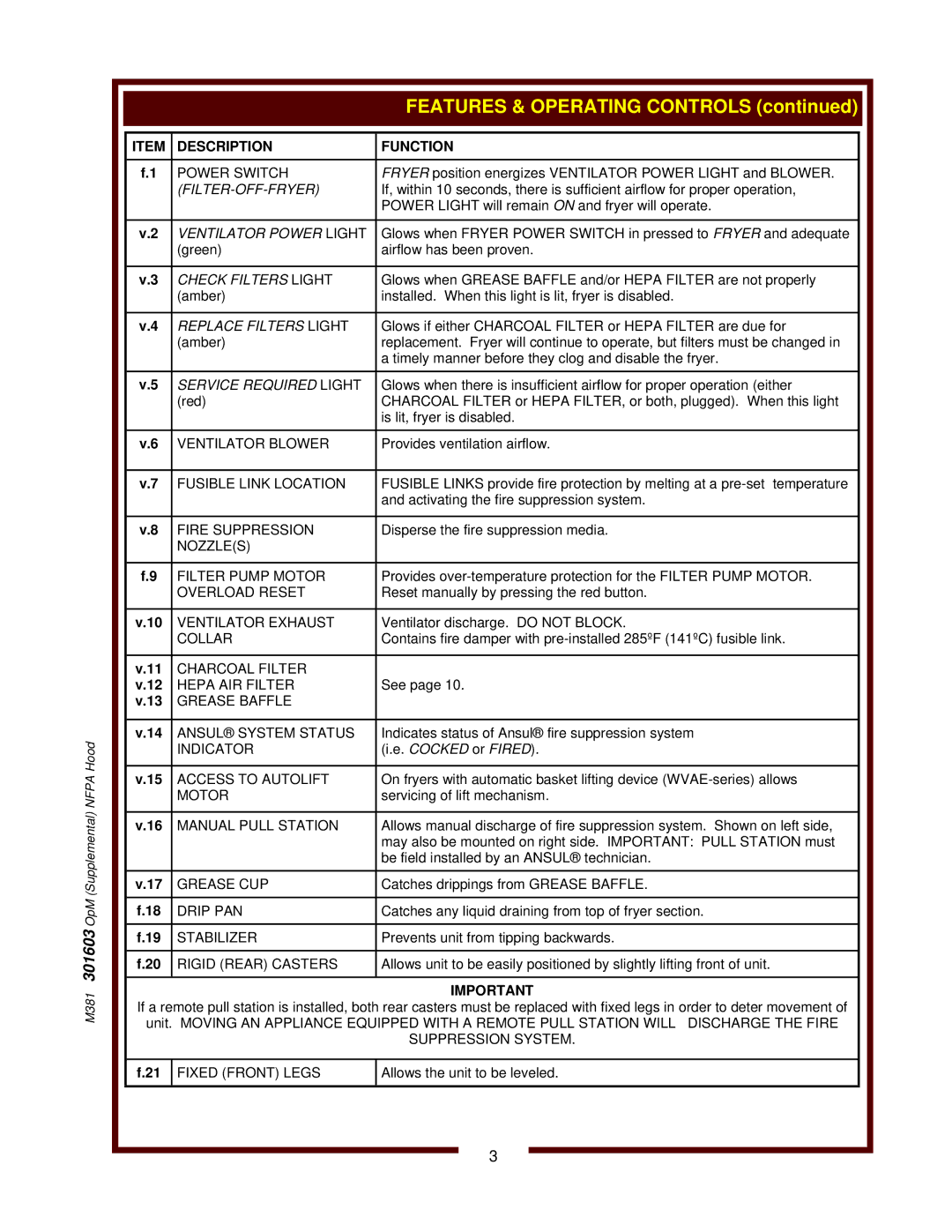

ITEM | DESCRIPTION | FUNCTION |

|

|

|

f.1 | POWER SWITCH | FRYER position energizes VENTILATOR POWER LIGHT and BLOWER. |

|

| If, within 10 seconds, there is sufficient airflow for proper operation, |

|

| POWER LIGHT will remain ON and fryer will operate. |

|

|

|

v.2 | VENTILATOR POWER LIGHT | Glows when FRYER POWER SWITCH in pressed to FRYER and adequate |

| (green) | airflow has been proven. |

|

|

|

v.3 | CHECK FILTERS LIGHT | Glows when GREASE BAFFLE and/or HEPA FILTER are not properly |

| (amber) | installed. When this light is lit, fryer is disabled. |

|

|

|

v.4 | REPLACE FILTERS LIGHT | Glows if either CHARCOAL FILTER or HEPA FILTER are due for |

| (amber) | replacement. Fryer will continue to operate, but filters must be changed in |

|

| a timely manner before they clog and disable the fryer. |

|

|

|

v.5 | SERVICE REQUIRED LIGHT | Glows when there is insufficient airflow for proper operation (either |

| (red) | CHARCOAL FILTER or HEPA FILTER, or both, plugged). When this light |

|

| is lit, fryer is disabled. |

|

|

|

v.6 | VENTILATOR BLOWER | Provides ventilation airflow. |

|

|

|

v.7 | FUSIBLE LINK LOCATION | FUSIBLE LINKS provide fire protection by melting at a |

|

| and activating the fire suppression system. |

|

|

|

v.8 | FIRE SUPPRESSION | Disperse the fire suppression media. |

| NOZZLE(S) |

|

|

|

|

f.9 | FILTER PUMP MOTOR | Provides |

| OVERLOAD RESET | Reset manually by pressing the red button. |

|

|

|

v.10 | VENTILATOR EXHAUST | Ventilator discharge. DO NOT BLOCK. |

| COLLAR | Contains fire damper with |

|

|

|

v.11 | CHARCOAL FILTER |

|

v.12 | HEPA AIR FILTER | See page 10. |

v.13 | GREASE BAFFLE |

|

|

|

|

v.14 | ANSUL® SYSTEM STATUS | Indicates status of Ansul® fire suppression system |

| INDICATOR | (i.e. COCKED or FIRED). |

|

|

|

v.15 | ACCESS TO AUTOLIFT | On fryers with automatic basket lifting device |

| MOTOR | servicing of lift mechanism. |

|

|

|

v.16 | MANUAL PULL STATION | Allows manual discharge of fire suppression system. Shown on left side, |

|

| may also be mounted on right side. IMPORTANT: PULL STATION must |

|

| be field installed by an ANSUL® technician. |

|

|

|

v.17 | GREASE CUP | Catches drippings from GREASE BAFFLE. |

|

|

|

f.18 | DRIP PAN | Catches any liquid draining from top of fryer section. |

|

|

|

f.19 | STABILIZER | Prevents unit from tipping backwards. |

|

|

|

f.20 | RIGID (REAR) CASTERS | Allows unit to be easily positioned by slightly lifting front of unit. |

|

|

|

IMPORTANT

If a remote pull station is installed, both rear casters must be replaced with fixed legs in order to deter movement of unit. MOVING AN APPLIANCE EQUIPPED WITH A REMOTE PULL STATION WILL DISCHARGE THE FIRE SUPPRESSION SYSTEM.

f.21 | FIXED (FRONT) LEGS | Allows the unit to be leveled. |

|

|

|

3