These include push sticks, feather boards, filler pieces, fixtures, jigs and any other appropriate device that can be utilized to keep operator's hands away from the blade. Upon completion of the operation requiring removal of the guard, the entire guard assembly must be placed back on the machine in its proper working order.

![]() Never use a dado head in a tilted position. Never operate the saw without the blade guard, splitter and

Never use a dado head in a tilted position. Never operate the saw without the blade guard, splitter and

Safety Devices

Feather Board

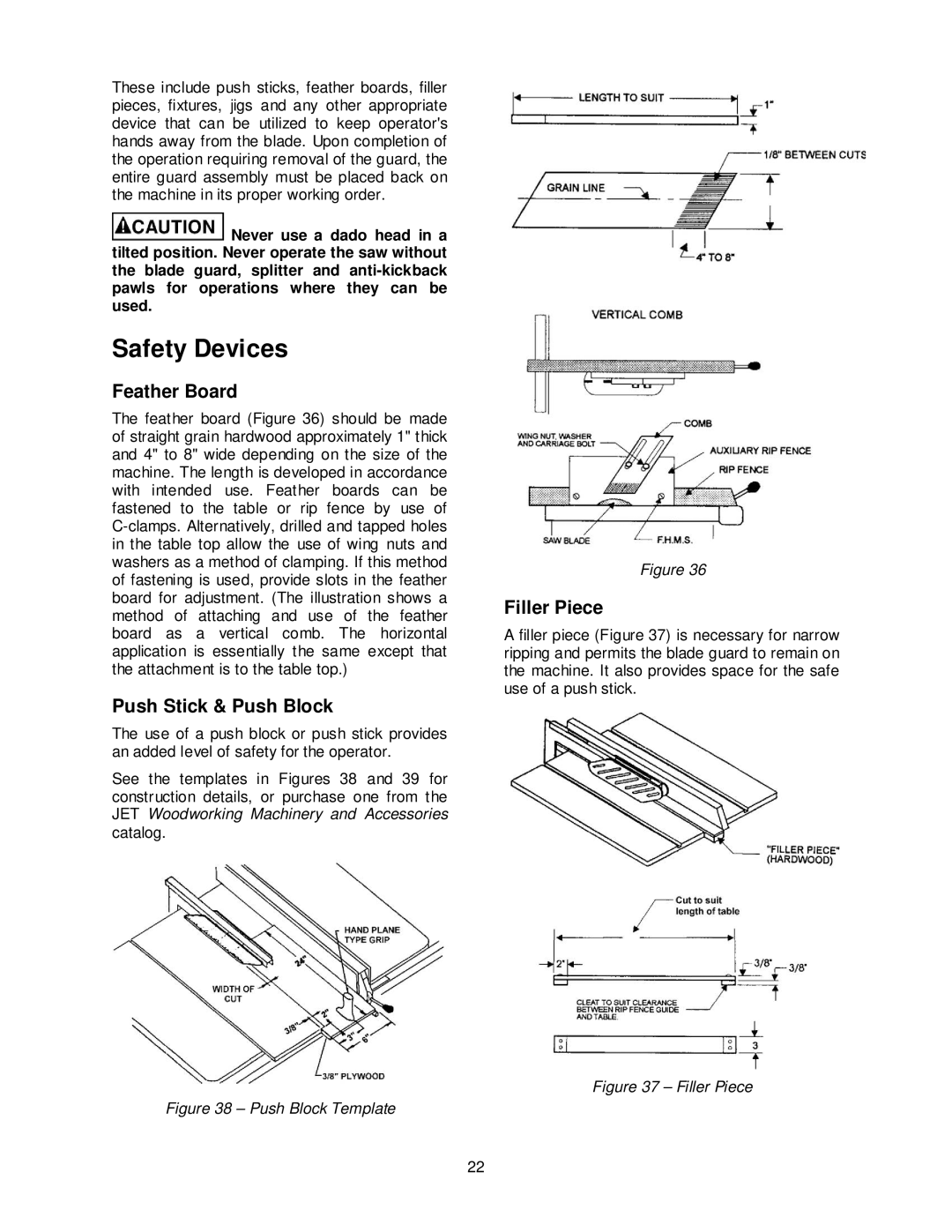

The feather board (Figure 36) should be made of straight grain hardwood approximately 1" thick and 4" to 8" wide depending on the size of the machine. The length is developed in accordance with intended use. Feather boards can be fastened to the table or rip fence by use of

Push Stick & Push Block

The use of a push block or push stick provides an added level of safety for the operator.

See the templates in Figures 38 and 39 for construction details, or purchase one from the JET Woodworking Machinery and Accessories catalog.

Figure 38 – Push Block Template

Figure 36

Filler Piece

A filler piece (Figure 37) is necessary for narrow ripping and permits the blade guard to remain on the machine. It also provides space for the safe use of a push stick.

Figure 37 – Filler Piece

22