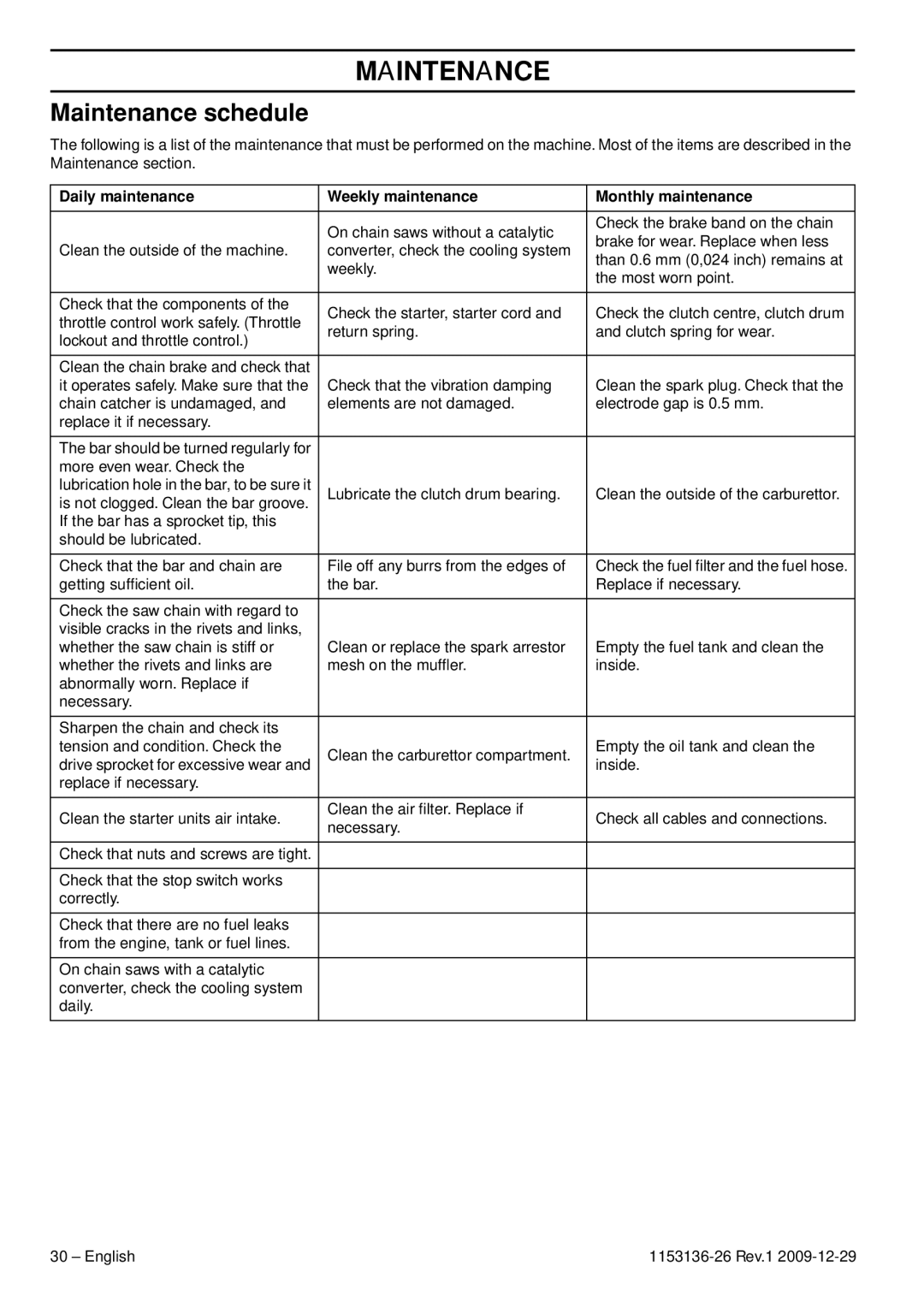

MAINTENANCE

General

The user must only carry out the maintenance and service work described in this Operator’s Manual. More extensive work must be carried out by an authorized service workshop.

Carburettor adjustment

Your Husqvarna product has been designed and manufactured to specifications that reduce harmful emissions.

Function

•The carburettor governs the engine’s speed via the throttle control. Air and fuel are mixed in the carburettor. The air/fuel mixture is adjustable. Correct adjustment is essential to get the best performance from the machine.

•The

Basic settings and running in

The basic carburettor settings are adjusted during testing at the factory. Fine adjustment should be carried out by a skilled technician.

Rec. idle speed: See the Technical data section.

Fine adjustment of the idle speed T

Adjust the idle speed with the

WARNING! Contact your servicing

! dealer, if the idle speed setting cannot be adjusted so that the chain stops. Do not use the chain saw until it has been properly adjusted or repaired.

Correctly adjusted carburettor

When the carburettor is correctly adjusted the machine accelerates without hesitation and

Checking, maintaining and servicing chain saw safety equipment

Note! All service and repair work on the machine demands special training. This is especially true of the machine’s safety equipment. If your machine fails any of the checks described below we recommend that you take it to your service workshop.

Chain brake and front hand guard

Checking brake band wear

Brush off any wood dust, resin and dirt from the chain brake and clutch drum. Dirt and wear can impair operation of the brake. (91)

Regularly check that the brake band is at least 0.6 mm thick at its thinnest point.

Checking the front hand guard

Make sure the front hand guard is not damaged and that there are no visible defects such as cracks.

Move the front hand guard forwards and back to make sure it moves freely and that it is securely anchored to the clutch cover.

Checking the inertia brake release

Place the chain saw, with the engine switched off, on a stump or other stable surface. Release the front handle and let the saw fall by its own weight, rotating around the rear handle towards the stump. (92)

When the bar hits the stump the brake should be applied. (93)

Checking the brake trigger

Place the chain saw on firm ground and start it. Make sure the chain does not touch the ground or any other object. See the instructions under the heading Start and stop.

(94)

Grasp the chain saw firmly, wrapping your fingers and thumbs around the handles. (56)

Apply full throttle and activate the chain brake by tilting your left wrist forward onto the front hand guard. Do not let go of the front handle. The chain should stop

immediately. (52)

26 – English |