40KMC------301, 40KMQ------301 specifications

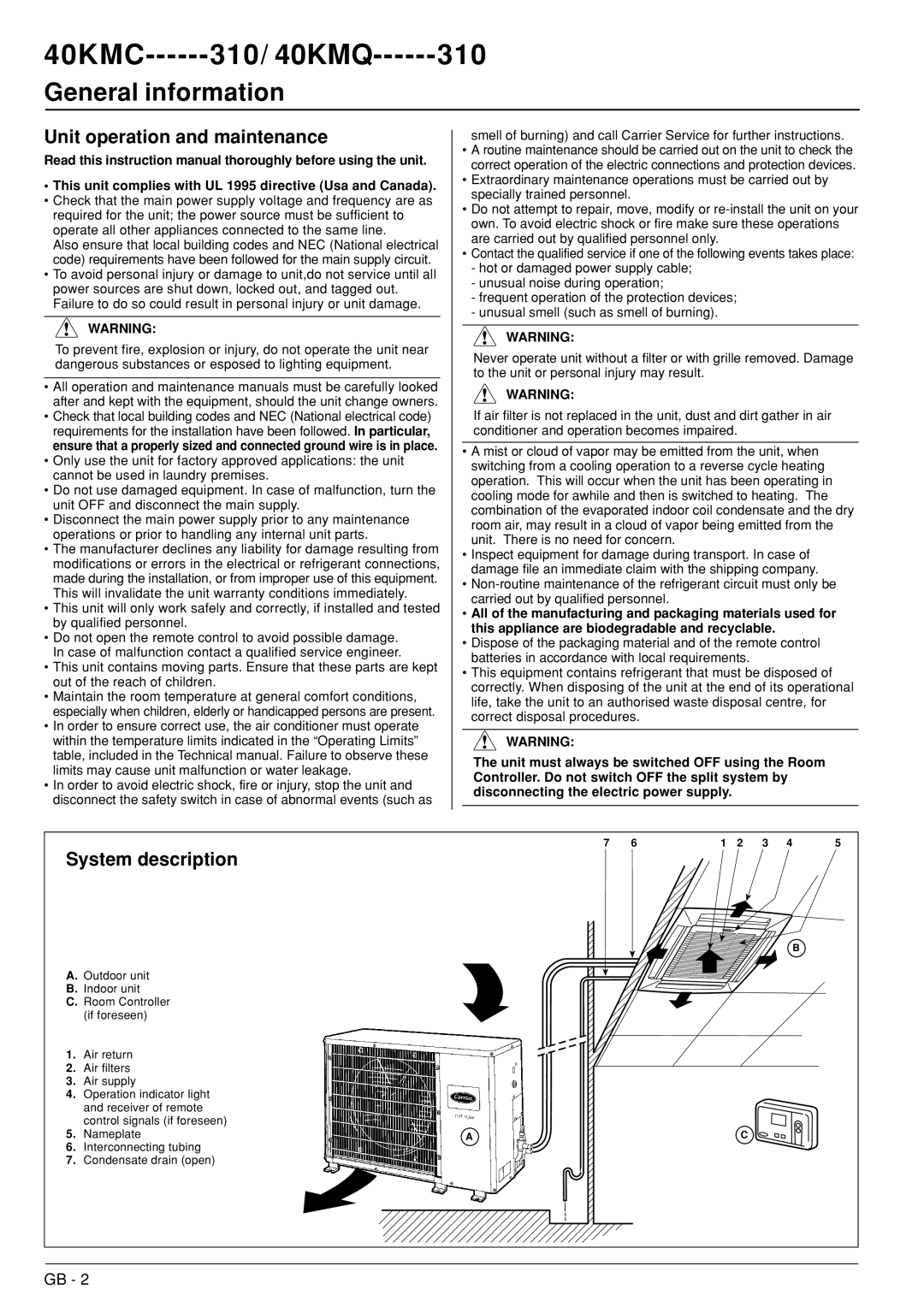

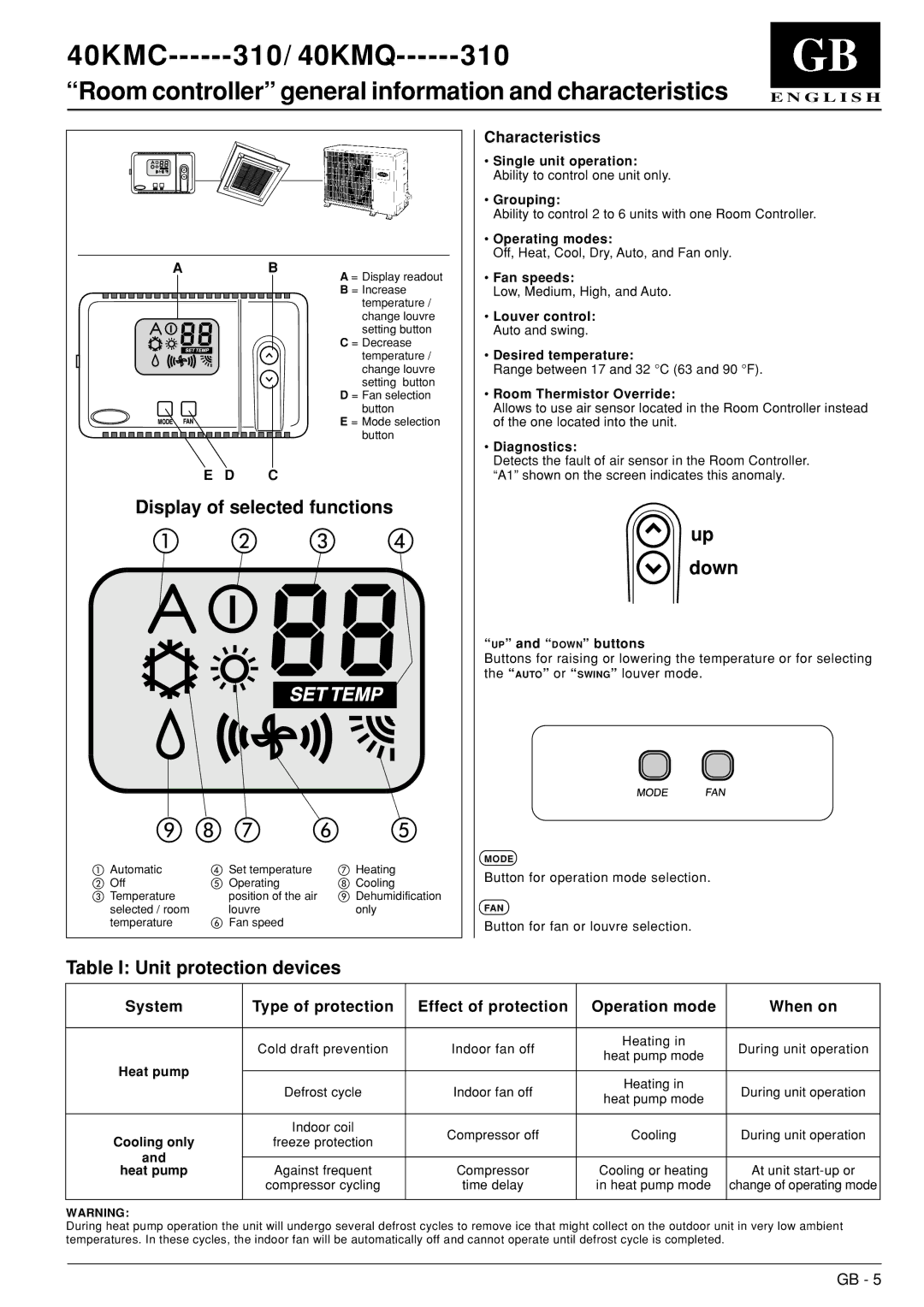

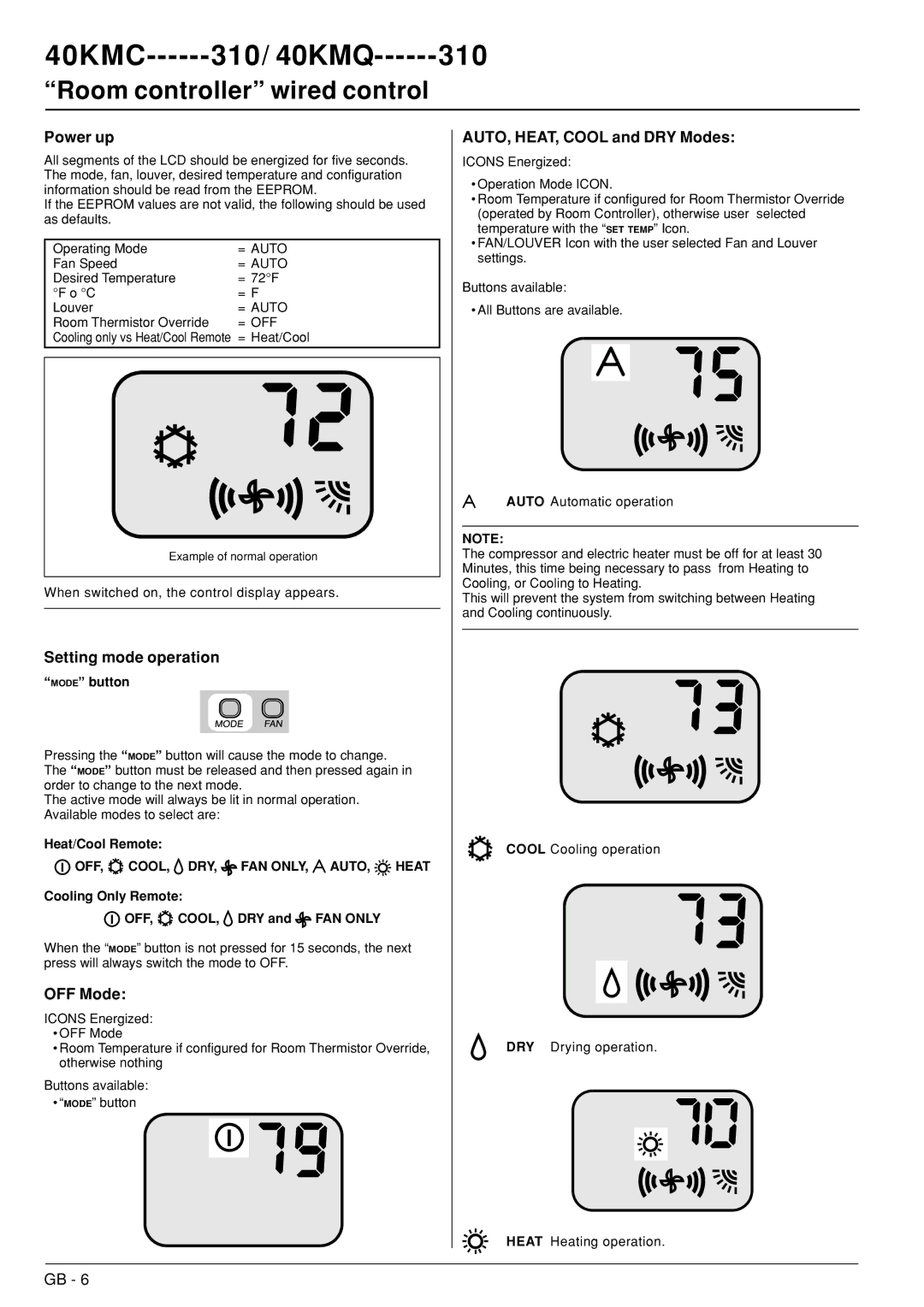

Carrier has been a pioneer in the HVAC industry, consistently delivering innovative solutions that prioritize energy efficiency and performance. Among its notable offerings are the Carrier 40KMQ-301 and 40KMC-301 models, which exemplify advanced technologies designed to meet diverse cooling needs.The Carrier 40KMQ-301 is part of Carrier's ducted split systems, designed primarily for commercial applications. This model boasts a robust cooling capacity, making it suitable for larger spaces that demand efficient climate control. Its key feature includes a high-efficiency scroll compressor, which enhances energy performance while reducing operational noise. Additionally, the 40KMQ-301 includes an advanced microprocessor control system, allowing for precise temperature management and real-time monitoring.

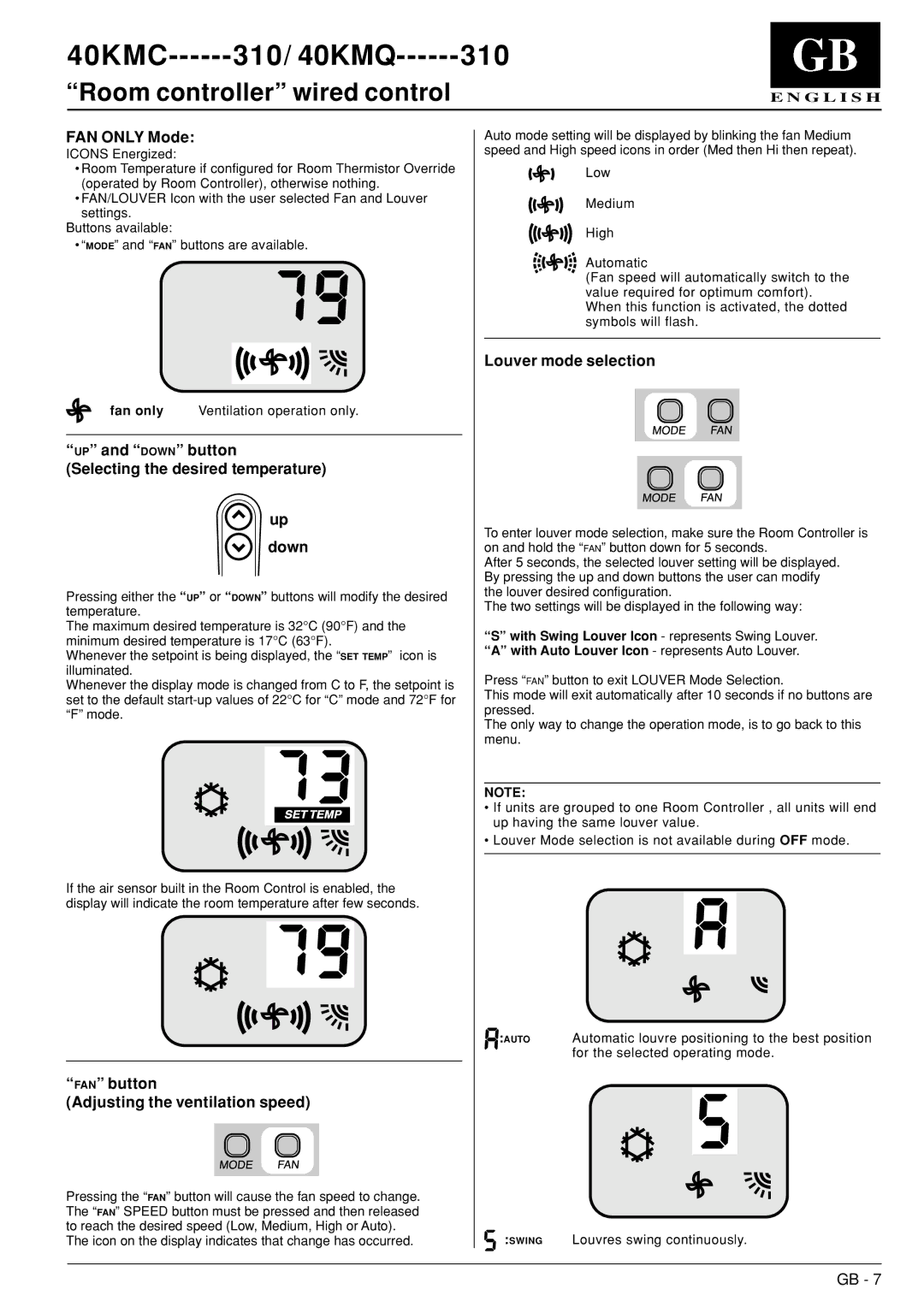

On the other hand, the Carrier 40KMC-301 operates as a multi-split system, providing flexible cooling options for various configurations. This model allows for multiple indoor units to be connected to a single outdoor condenser, optimizing space without compromising performance. The 40KMC-301 emphasizes energy saving, achieving high SEER (Seasonal Energy Efficiency Ratio) ratings, which reflects its efficiency in both cooling and heating modes.

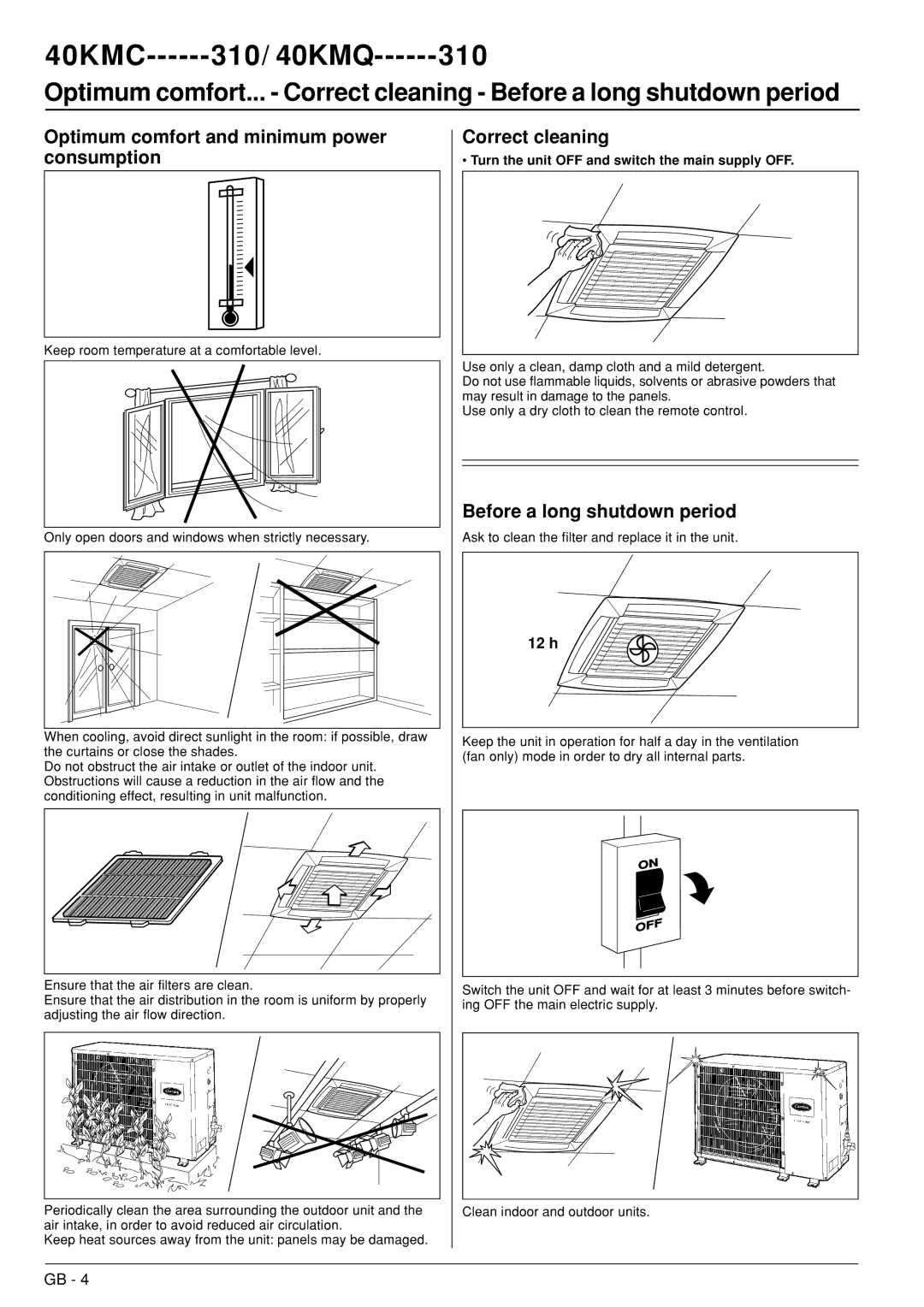

Both models incorporate Carrier's innovative environmentally friendly refrigerants, ensuring less impact on the ozone layer while maintaining high thermal efficiency. Furthermore, they come equipped with a range of airflow configurations, allowing users to tailor the distribution of air according to their unique layout and design requirements.

Durability is another hallmark of these models; they feature corrosion-resistant cabinets that withstand harsh environmental conditions, ensuring longevity and reducing maintenance costs. Integration with smart building technologies is also a highlight, allowing for seamless connectivity with building management systems.

In conclusion, the Carrier 40KMQ-301 and 40KMC-301 represent the forefront of HVAC technology, characterized by high efficiency, flexibility, and advanced control systems. These models not only provide reliable cooling solutions but also contribute to overall energy savings, positioning Carrier as a leader in the sustainable HVAC market.