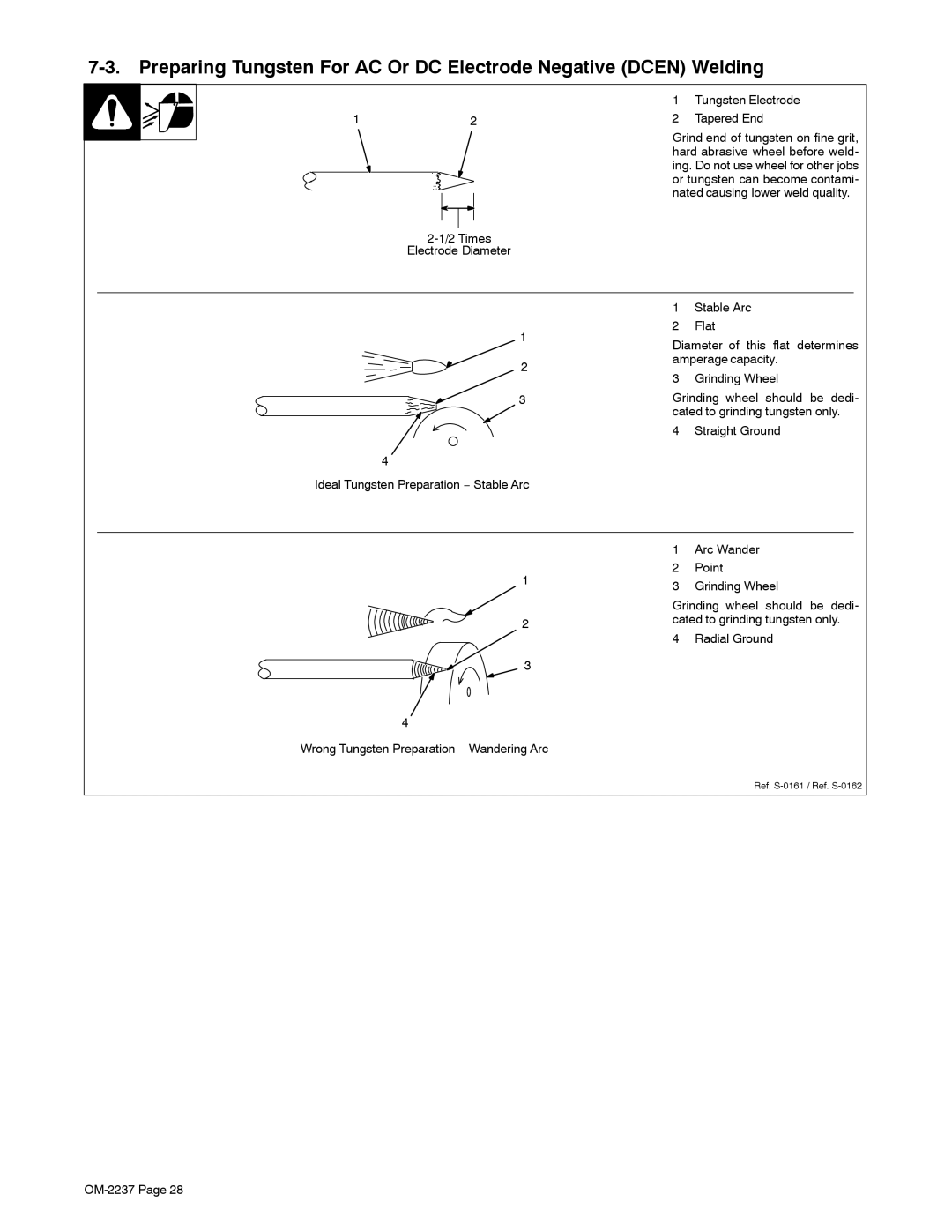

SECTION 7 − SELECTING AND PREPARING TUNGSTEN

ELECTRODE

gtaw 7/97

NOTE

For additional information, see your distributor for a handbook on the Gas Tungsten Arc Welding (GTAW) process.Wear clean gloves to prevent contamination of tungsten electrode.

7-1. Selecting Tungsten Electrode

|

| Amperage Range - Gas Type♦ - Polarity |

| |

|

|

|

|

|

Electrode Diameter | DC − Argon − Electrode | DC − Argon − Electrode | AC − Argon − Using | AC − Argon − Balanced |

| Negative/Straight Polarity | Positive/Reverse Polarity | High Frequency | Wave Using High Freq. |

|

|

|

|

|

2% Thorium Alloyed |

|

|

|

|

Tungsten (Red Band) |

|

|

|

|

|

|

|

|

|

.010” | Up to 25 | * | Up to 20 | Up to 15 |

.020” | * | |||

.040” | * | |||

1/16” | ||||

3/32” | ||||

1/8” | ||||

5/32” | ||||

3/16” | ||||

1/4” | ||||

|

|

|

|

|

♦Typical argon shielding gas flow rates are 15 to 35 cfh (cubic feet per hour).

*Not Recommended.

The figures listed are intended as a guide and are a composite of recommendations from American Welding Society (AWS) and electrode manufacturers.

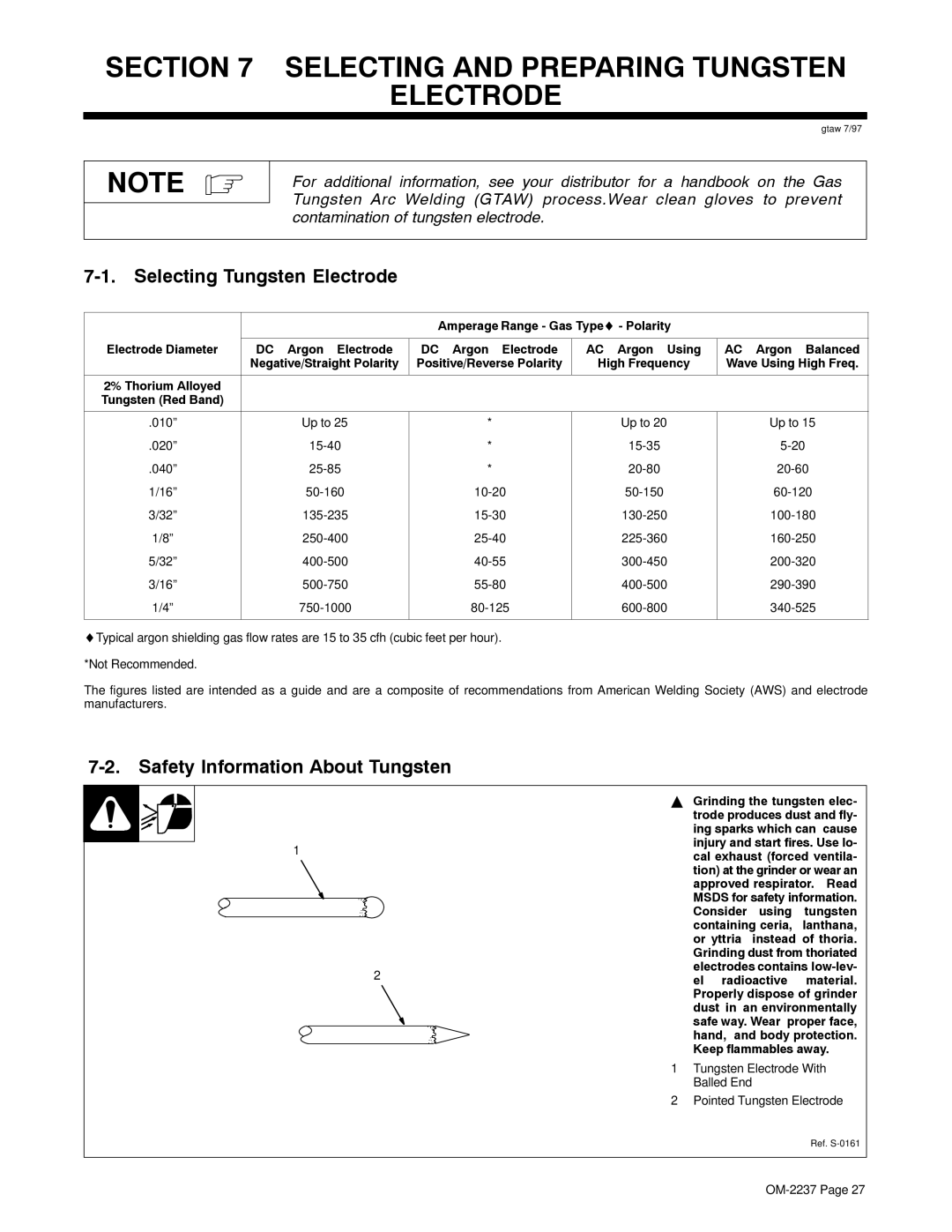

7-2. Safety Information About Tungsten

Y Grinding the tungsten elec-

| trode produces dust and fly- | |||

| ing sparks which can cause | |||

1 | injury and start fires. Use lo- | |||

cal exhaust (forced ventila- | ||||

| ||||

| tion) at the grinder or wear an | |||

| approved respirator. Read | |||

| MSDS for safety information. | |||

| Consider | using | tungsten | |

| containing ceria, | lanthana, | ||

| or yttria | instead of thoria. | ||

| Grinding dust from thoriated | |||

2 | electrodes contains | |||

el radioactive | material. | |||

| ||||

| Properly dispose of grinder | |||

| dust in an environmentally | |||

| safe way. Wear proper face, | |||

| hand, and body protection. | |||

| Keep flammables away. | |||

1 | Tungsten Electrode With | |||

| Balled End |

|

| |

2 | Pointed Tungsten Electrode | |||

Ref.