3. PRE-INSTALLATION CHECKLIST

IMPORTANT STEPS AND DECISIONS REQUIRED BEFORE INSTALLATION

j THIS PRODUCT MUST BE INSTALLED AND MAINTAINED BY A LICENSED PROFESSIONAL. IN ADDITION TO THE INSTRUCTIONS IN THIS MANUAL, FOLLOW ALL APPLICABLE LOCAL AND STATE CODES OR IN THE ABSENCE OF SUCH CODES, THE CURRENT EDITIONS OF THE NATIONAL PLUMBING CODE AND THE NATIONAL ELECTRIC CODE.

jDRIP PAN AND DRAIN: To avoid leaking and/or flooding damage, install with a drip pan connected to an adequate working drain kept clear at all times.

4.REQUIRED COMPONENTS AND ACCESSORIES CHECKLIST

VERTICAL STAND MODELS

j 1. PRESSURE SWITCH | j 5. VALVE DRAIN | |

j 2. | RELIEF VALVE | j 6. PRESSURE GAUGE |

j 3. | 1 UNION | j 7. |

j4. 1 SHUT OFF VALVE

MAXIMUM WORKING PRESSURES

![]() Every well tank is air tested to 100 psig, the maximum working pressure for the well tank line.

Every well tank is air tested to 100 psig, the maximum working pressure for the well tank line.

RELIEF VALVE RECOMMENDED

![]() It is recommended that a relief valve be installed which is set to open at excessive pressures (75 psig or more). This will protect your well tank and other system components should the pressure switch malfunction and fail to shut the pump off. The relief valve should be installed at the connection of your well tank to the system piping and have a discharge equal to the pump’s capacity at 75 psig.

It is recommended that a relief valve be installed which is set to open at excessive pressures (75 psig or more). This will protect your well tank and other system components should the pressure switch malfunction and fail to shut the pump off. The relief valve should be installed at the connection of your well tank to the system piping and have a discharge equal to the pump’s capacity at 75 psig.

5. INSTALLATION INSTRUCTIONS

Location

Proper well tank Location

The well tank should be installed as close as possible to the pressure switch. This will reduce the adverse effects of added friction loss and pressure switch bouncing, and the difference in elevation between well tank and switch.

![]() DANGER! EXPLOSION HAZARD. WHEN THE WELL

DANGER! EXPLOSION HAZARD. WHEN THE WELL ![]() TANK HAS BEEN IN SERVICE AND A CHANGE TO A HIGHER

TANK HAS BEEN IN SERVICE AND A CHANGE TO A HIGHER

CHANGE IN THE PRESSURE SWITCH SETTING, FAILURE TO FOLLOW INSTRUCTIONS BELOW CAN CAUSE A RUPTURE OR EXPLOSION, POSSIBLY CAUSING SERIOUS OR FATAL INJURY, AND/OR PROPERTY DAMAGE.

•DO NOT ADJUST OR ADD PRESSURE IF THERE HAS BEEN A LOSS OF

AIR.

•DO NOT ADJUST THE

EXTERIOR CORROSION.

•DO NOT ADJUST THE

REDUCTION OF THE PUMP CYCLE TIME OR THE

Explosion Hazard. Failure to follow ![]() these instructions can cause a rupture or explosion possibly causing serious or fatal injury, flooding, and / or property damage.

these instructions can cause a rupture or explosion possibly causing serious or fatal injury, flooding, and / or property damage.

System Connection

1.Locate your well tank in the final desired location.

2.Level as necessary.

3.To eliminate friction loss, do not reduce the pipe size from the pump to the well tank.

Start Up

Fine Tuning Procedures

Many times the actual pressure switch will vary from the standard pressure range indicated. These variations could cause a momentary lag of water delivery, as the pressure switch is not “tuned to the well tank precharge pressure”.

1.Fill the system and well tank until pump cuts off.

2.Open one or more fixtures to drain the well tank.

3.If there is a momentary pause in the water flow from the time the well tank is emptied and the pump starts, adjust pump

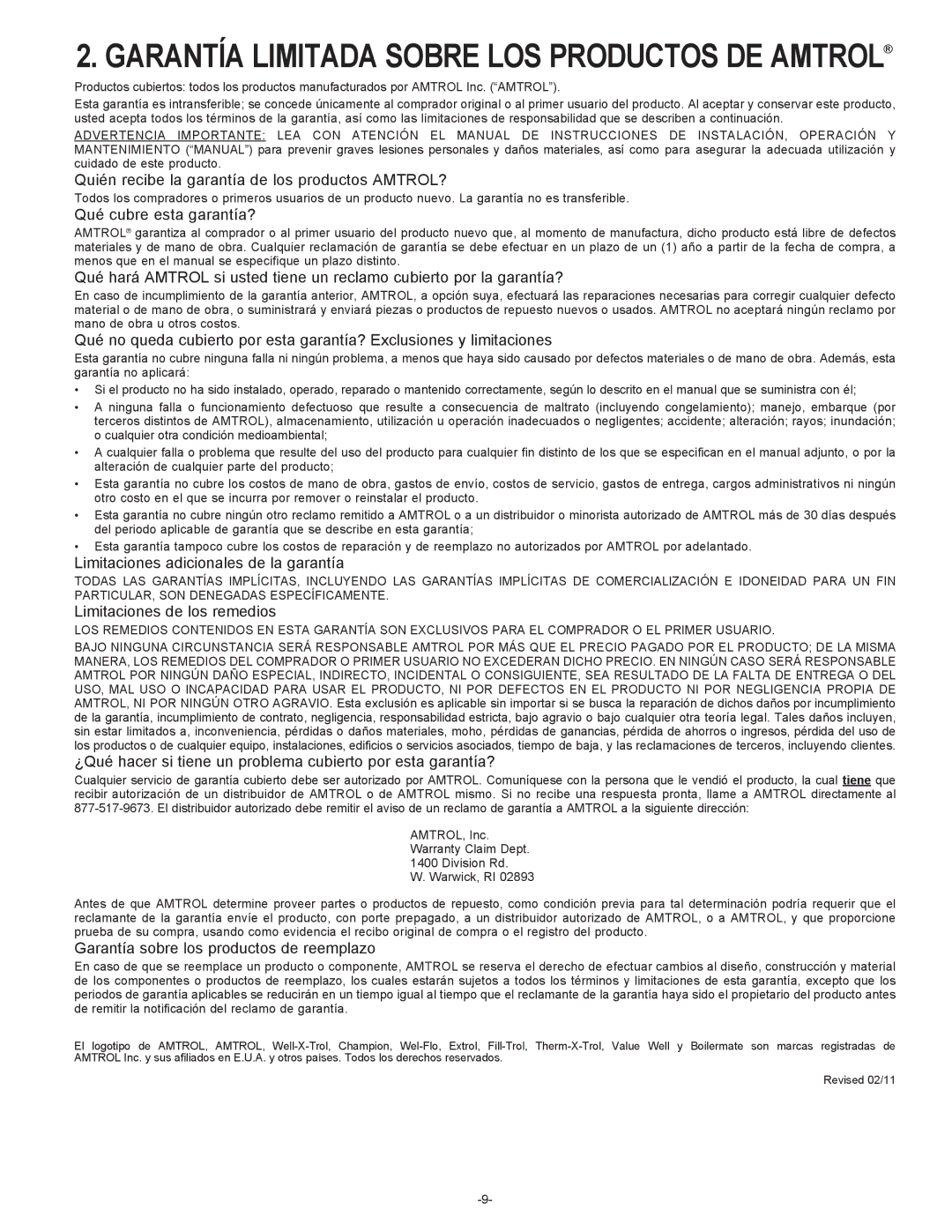

Adjusting Precharge

Prior to Installation

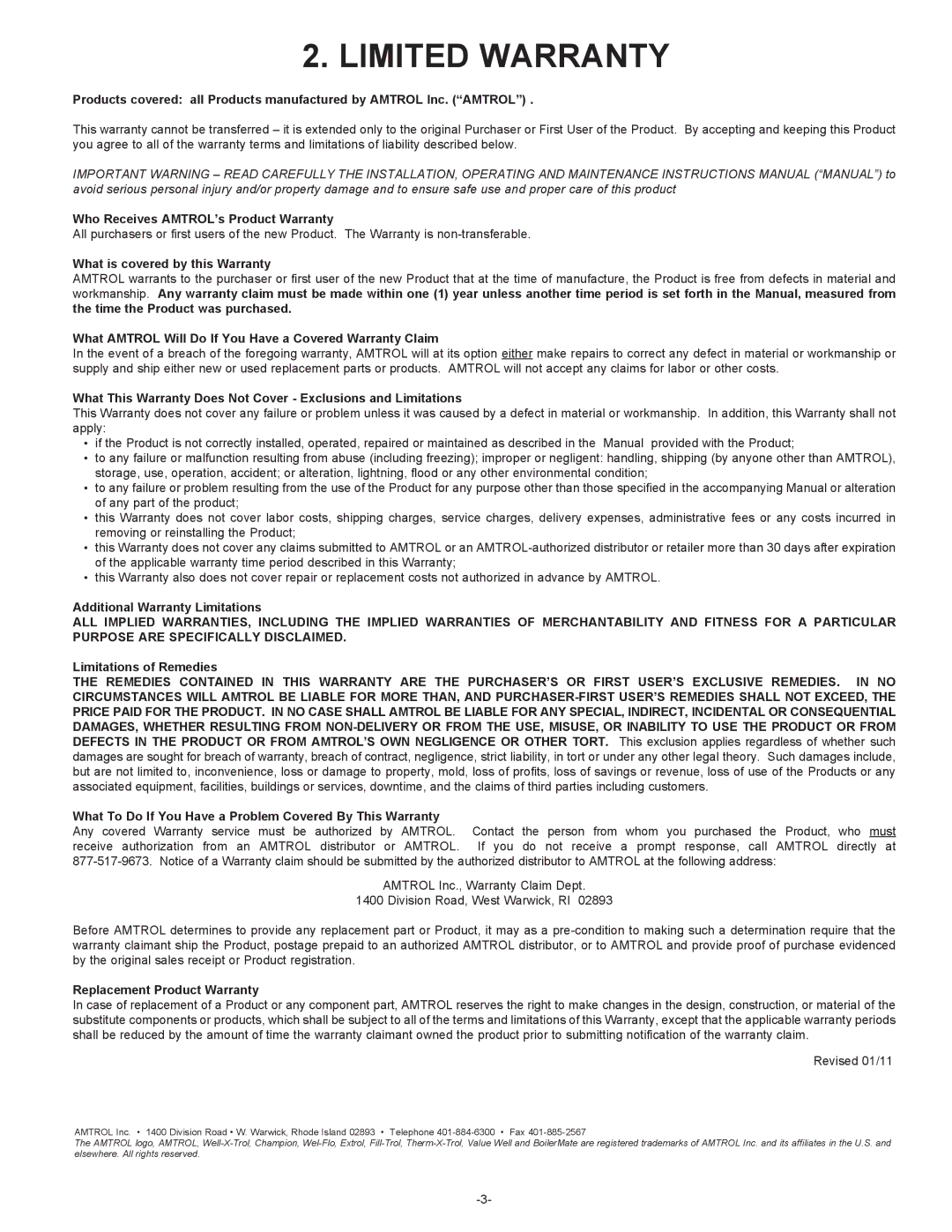

All well tanks are shipped with a standard precharge of 38 psig.

Step 1. Remove protective air valve cap

Step 2. Check precharge pressure should be + or - 10% of the factory setting)

Step 3. Release or add air as necessary to make the precharge pressure 2 psig below the pressure switch pump

Step 4. Replace protective air valve cap. Peel off backing of label and apply over air valve cap.

AIR VALVE

LABEL

AIR

VALVE

CAP

AIR VALVE LABEL

IN POSITION

OVER CAP

FIGURE 1

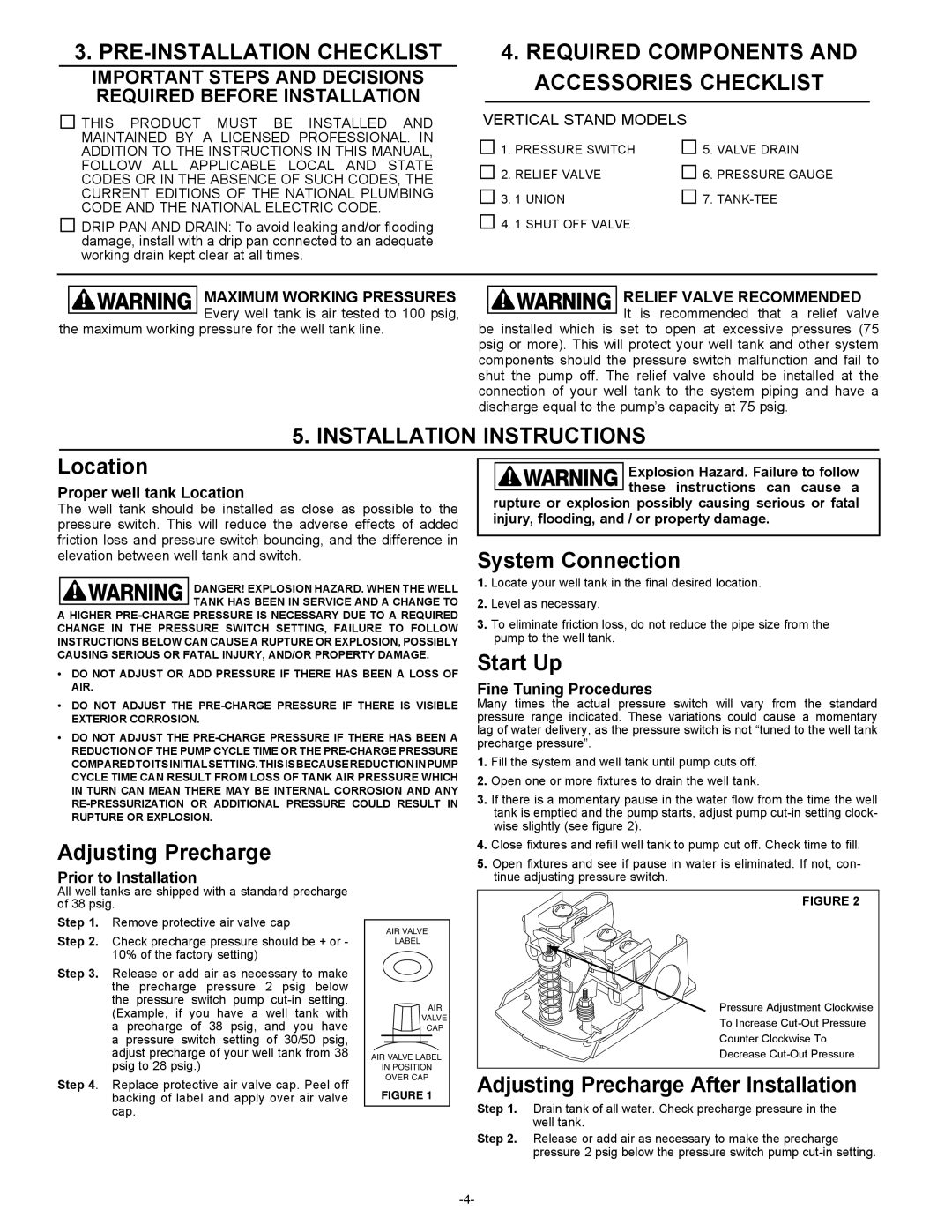

4.Close fixtures and refill well tank to pump cut off. Check time to fill.

5.Open fixtures and see if pause in water is eliminated. If not, con- tinue adjusting pressure switch.

FIGURE 2

Pressure Adjustment Clockwise

To Increase

Counter Clockwise To

Decrease

Adjusting Precharge After Installation

Step 1. Drain tank of all water. Check precharge pressure in the well tank.

Step 2. Release or add air as necessary to make the precharge pressure 2 psig below the pressure switch pump