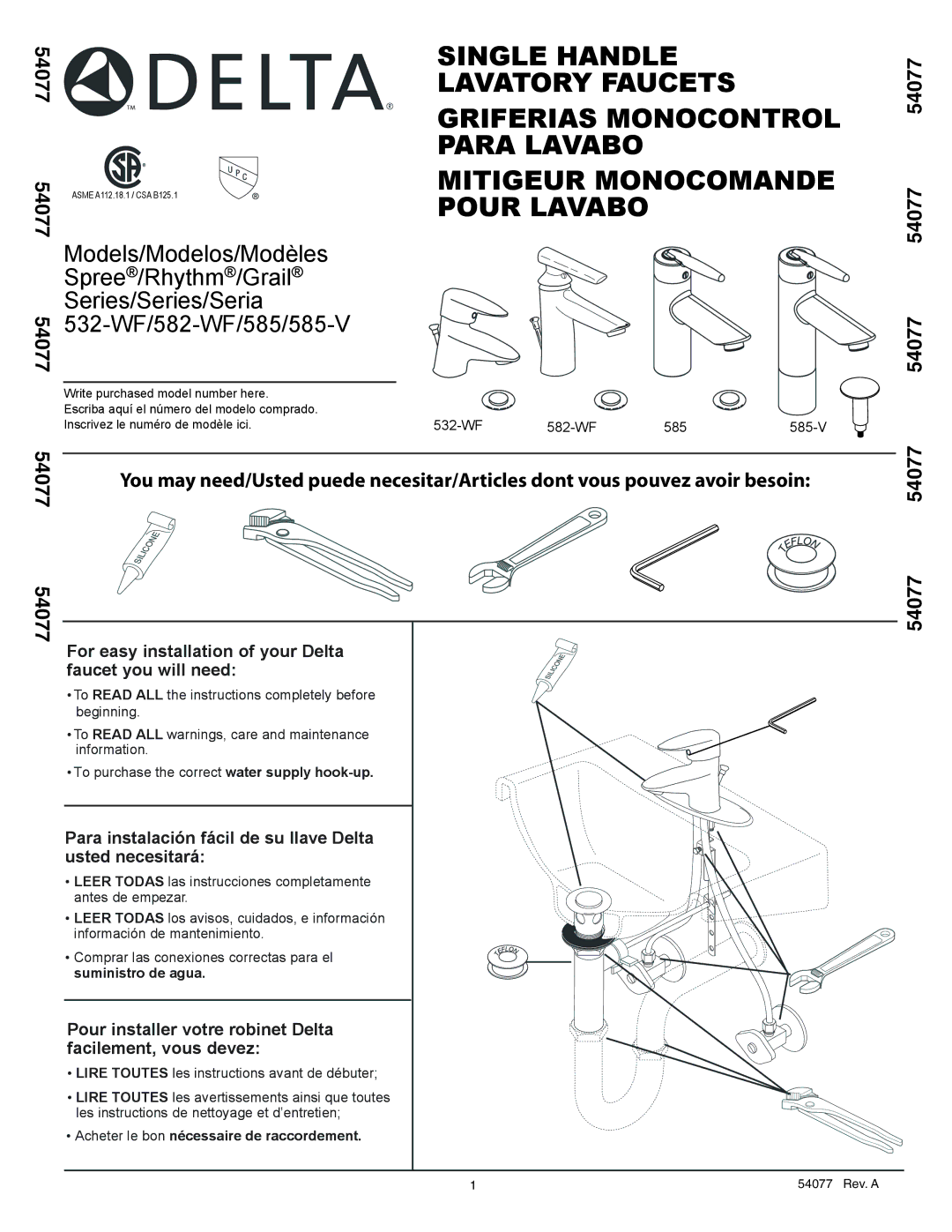

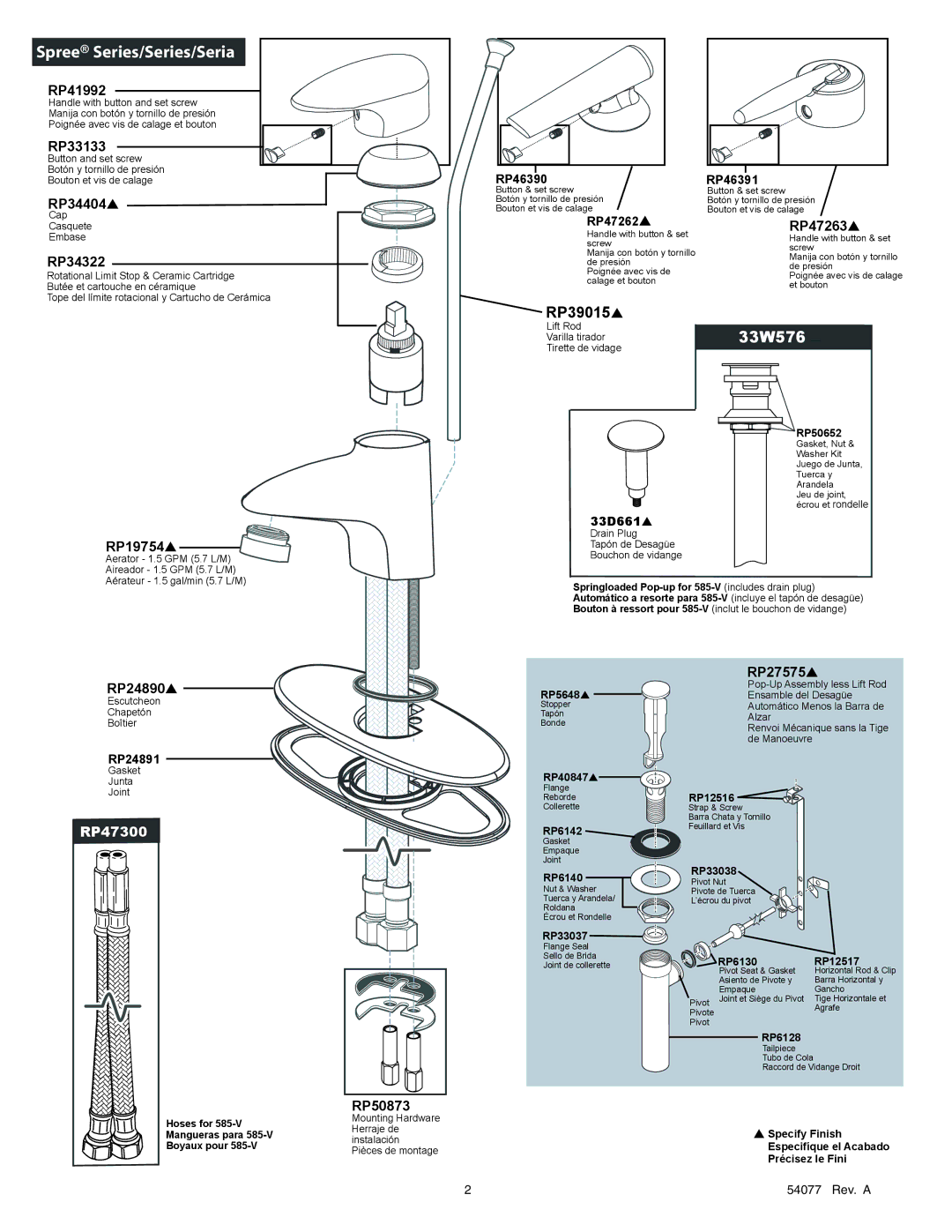

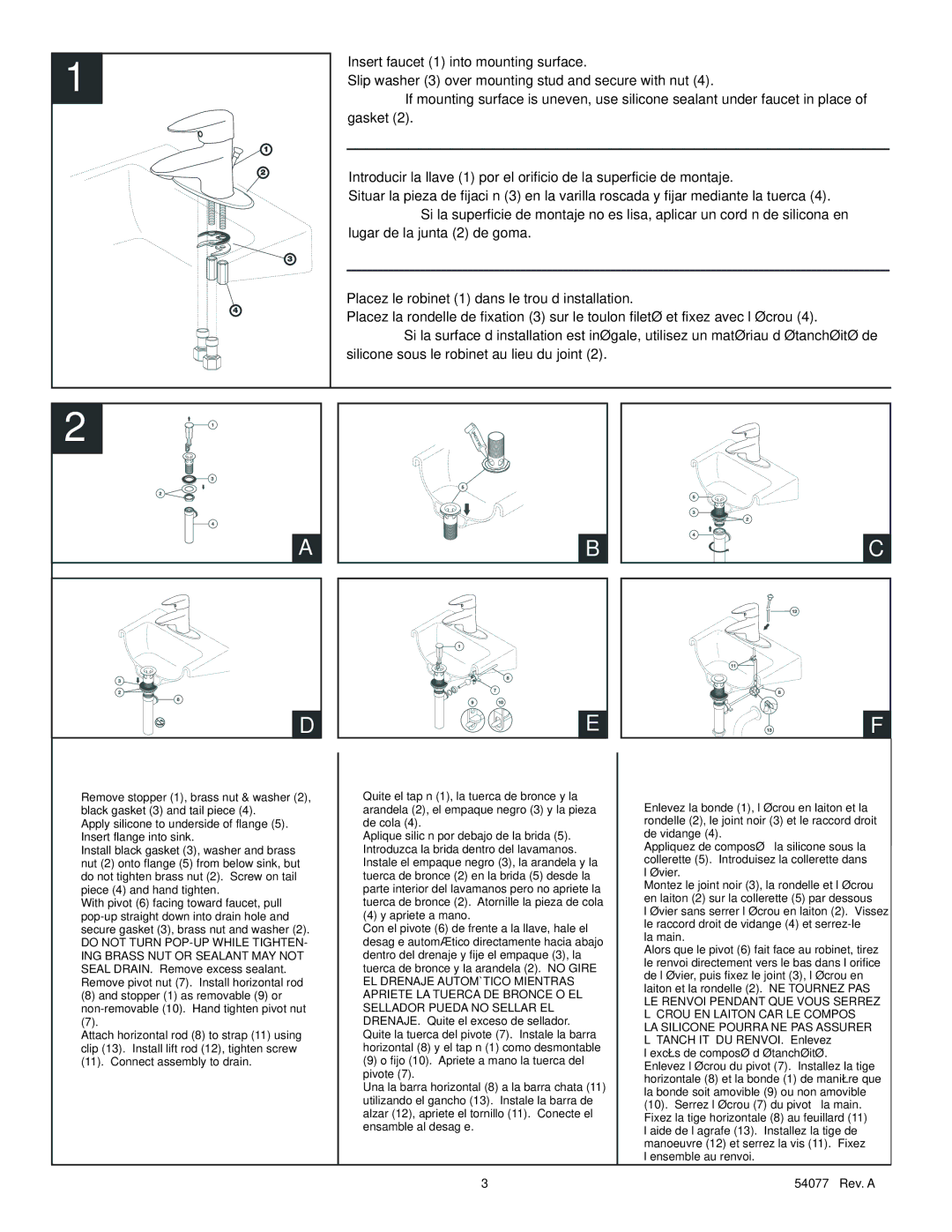

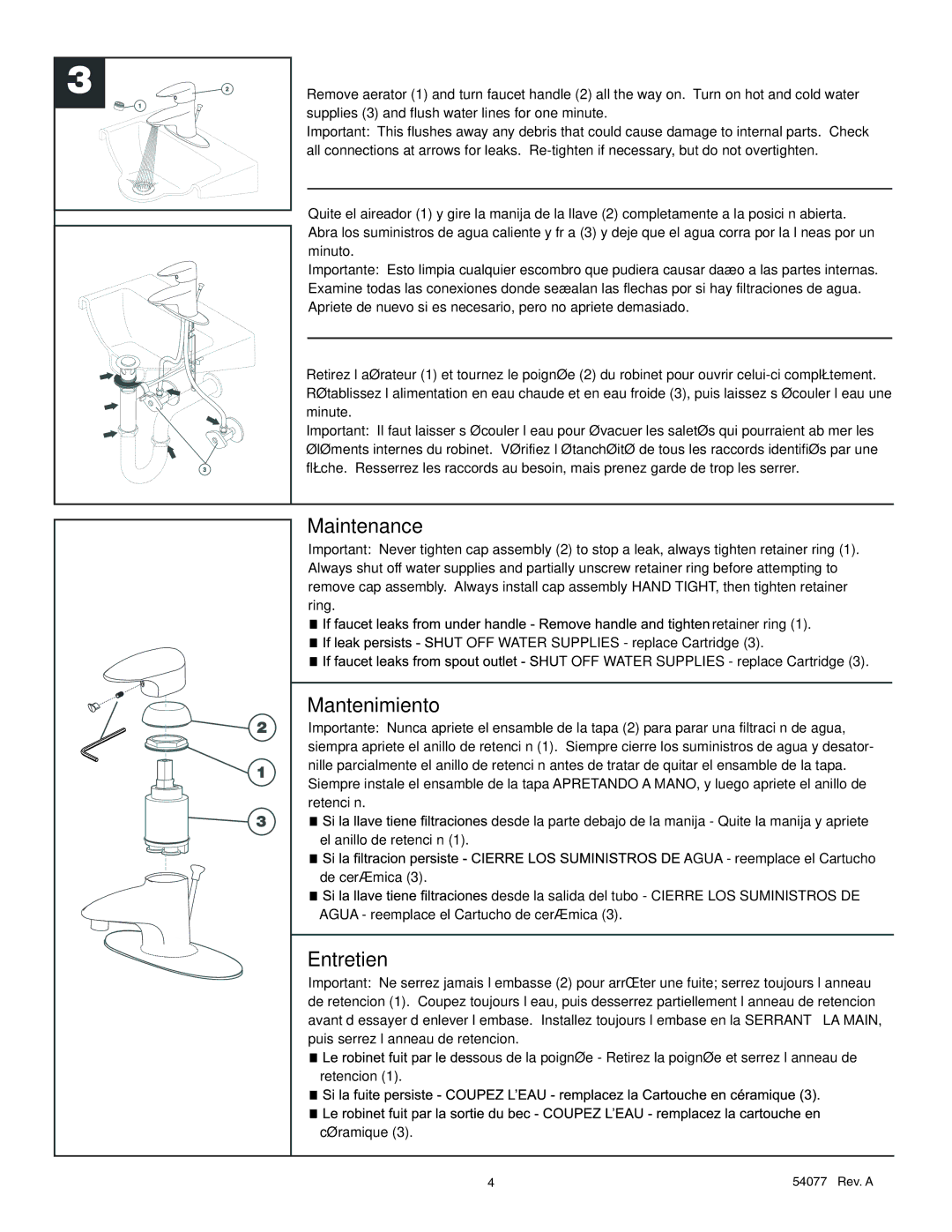

582-WF Series, 532-WF Series, 585 Series, 585-V Series specifications

The Delta 585 Series, 582-WF Series, 585-V Series, and 532-WF Series are renowned for their state-of-the-art design and innovative features that cater to a range of industrial and commercial applications. Each series incorporates advanced technologies to enhance performance, efficiency, and reliability.The Delta 585 Series is particularly notable for its high-speed operation and precision control. It utilizes cutting-edge servo technology, allowing for real-time adjustments and superior accuracy in various processes. The series also integrates advanced motion control features, enabling smooth operation even in demanding environments. Key characteristics include a robust construction that ensures durability and minimal maintenance, making it suitable for prolonged use in challenging conditions.

In contrast, the Delta 582-WF Series focuses on energy efficiency and environmental sustainability. This series is designed with intelligent power management systems that significantly reduce energy consumption without compromising performance. The 582-WF Series is particularly advantageous for applications where operational costs are a concern. Additionally, it features compact designs that facilitate easy installation and integration into existing systems, making it a popular choice among businesses looking to upgrade their machinery.

The Delta 585-V Series stands out for its versatility and modularity. This series allows users to tailor configurations to meet specific operational requirements, whether in manufacturing, packaging, or logistics. With features like adaptive learning algorithms, the 585-V Series optimizes performance based on real-time data feedback, thus enhancing productivity. Its user-friendly interface makes it accessible for operators, reducing training time and increasing overall effectiveness.

Lastly, the Delta 532-WF Series boasts remarkable robustness, making it ideal for heavy-duty applications. This series is engineered to handle extreme conditions, including temperature variations and heavy loads. It incorporates advanced safety features that protect the machinery and personnel alike. The 532-WF Series is designed for easy maintenance, with replaceable parts that contribute to lower downtime and operational interruptions.

In summary, the Delta 585 Series, 582-WF Series, 585-V Series, and 532-WF Series offer a range of features and technologies that cater to diverse industrial needs. From high-speed precision control to energy efficiency and robust durability, each series is designed to maximize productivity while minimizing operational costs. These characteristics make Delta products a preferred choice among professionals in various industries looking for reliable and advanced solutions.