ACGSS02407, BTH-120 through BTH-500 specifications

A.O. Smith is renowned for its innovative water heating solutions, and their BTH series, which ranges from BTH-120 to BTH-500, exemplifies this commitment to quality and efficiency. These models are designed for commercial applications, providing reliable performance for businesses in various industries.The BTH-120 to BTH-500 models feature a robust construction that ensures durability and longevity. Built with high-quality materials, these commercial water heaters are designed to withstand the rigors of heavy use. Their compact design makes them easy to install in limited spaces while maintaining high performance levels.

One of the standout features of the A.O. Smith BTH series is its advanced heating technology. These units utilize a high-efficiency gas burner system, providing rapid heating capabilities that ensure hot water is readily available when needed. This is particularly beneficial for businesses requiring consistent hot water supply, such as hotels, restaurants, and hospitals.

The BTH series also includes sophisticated controls that enhance user convenience and operational efficiency. With intuitive digital displays, operators can easily monitor temperature settings and operational status. This allows for precise control over heating schedules, which can lead to energy savings and improved operational effectiveness.

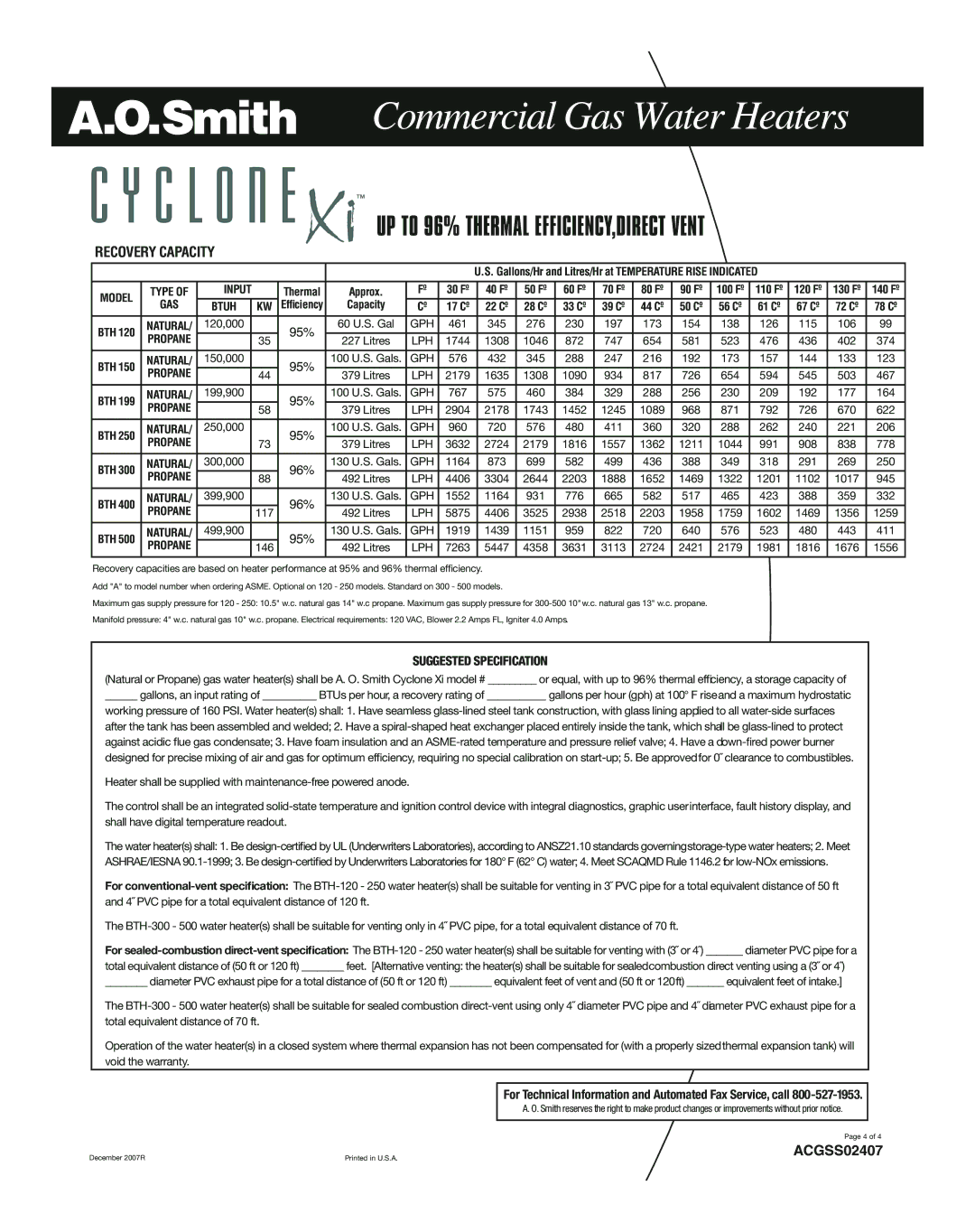

Another significant characteristic of the BTH models is their energy efficiency. These water heaters meet or exceed the latest energy standards, ensuring businesses can reduce their operational costs while being mindful of environmental impact. The high recovery rates of these units mean that they can provide substantial amounts of hot water without excessive energy consumption, making them a cost-effective option for any commercial setting.

Safety is also a paramount consideration in the design of the BTH series. These water heaters are equipped with multiple safety features, including thermal overload protection and integrated safety shut-off valves. This ensures peace of mind for operators, knowing that the system is designed to function safely under high demands.

In summary, A.O. Smith’s BTH-120 through BTH-500 models offer a combination of durability, advanced heating technology, user-friendly controls, energy efficiency, and safety features. These characteristics make them an ideal choice for various commercial applications, delivering performance and reliability that businesses can count on for their hot water needs.