Calibration -

The Answer to Reliable Detection

Ei CO alarms made to exceed BS EN 50291: 2001 -

Precise and reliable calibration is now even more important

The BS EN 50291 British and European Standard for CO Alarms requires a much lower trigger level than the previous BS 7860, which it supersedes. This is designed to give added protection to the more vulnerable members of society: the very young and the elderly. However, this can mean that nuisance alarm from very low levels of CO can occur if the sensor is not very accurately calibrated. To minimise this risk:

•Prior to alarm assembly every Ei CO sensor is independently calibrated at the factory in CO gas

•After alarm assembly every Ei CO Alarm is further tested in CO gas at the factory

These facts, coupled with sustained levels of quality throughout the manufacturing process ensure the very highest standard of reliability and immunity from nuisance alarm.

Comprehensive Precision Calibration and Testing at 5 stages of the

Manufacturing Process

1 2 3 4 5

Sensors mounted on bespoke calibration circuits are loaded into the CO enclosure, where the CO gas exposure program can be run.

As the CO gas exposure program is run, the sensors are subject to precise CO levels for set times with each sensor’s individual response being recorded by the calibration circuitry.

Once recorded, the sensors are loaded into a custom interface to extract data on each individual sensor’s response.

The sensors are analysed and are grouped according to their response. Each group is then installed into a specifically calibrated circuit within the alarm, ensuring that all alarms accurately respond when subjected to CO gas.

Following assembly, all finished alarms are functionally checked for response and accuracy in CO gas before despatch.

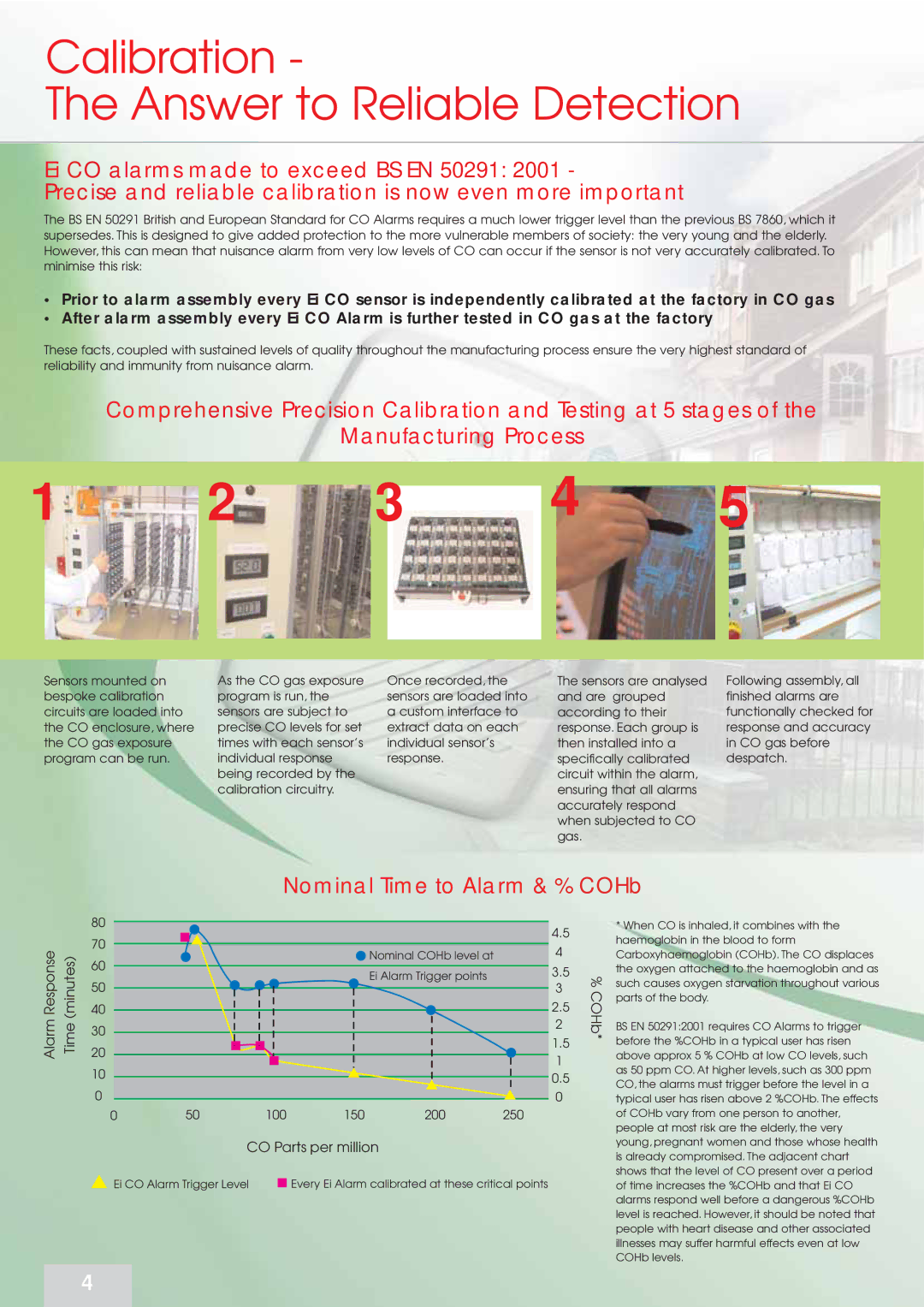

Nominal Time to Alarm & % COHb

80

70![]() ▲

▲

4.5

* When CO is inhaled, it combines with the haemoglobin in the blood to form

Response | (minutes) |

arm | Time |

60

50

40

30

![]() Nominal COHb level at

Nominal COHb level at

Ei Alarm Trigger points

Al |

20 |

|

|

|

|

|

|

|

|

|

|

|

|

| ▲ |

|

| |

10 |

|

|

|

|

|

|

| |

|

|

|

|

|

| ▲ | ▲ | |

0 |

|

|

|

|

|

| ||

|

|

|

|

|

|

| ||

| 50 | 100 | 150 | 200 | 250 | |||

0 | ||||||||

|

| CO Parts per million |

|

| ||||

▲ Ei CO Alarm Trigger Level |

|

|

| Every Ei Alarm calibrated at these critical points | ||||

|

|

| ||||||

|

|

| ||||||

3.5 | % | the oxygen attached to the haemoglobin and as | |

3 | such causes oxygen starvation throughout various | ||

COHb | parts of the body. | ||

2.5 | |||

| |||

2 | BS EN 50291:2001 requires CO Alarms to trigger | ||

1.5 | * | before the %COHb in a typical user has risen | |

|

1 | above approx 5 % COHb at low CO levels, such | |

as 50 ppm CO. At higher levels, such as 300 ppm | ||

0.5 | ||

CO, the alarms must trigger before the level in a | ||

|

0typical user has risen above 2 %COHb. The effects of COHb vary from one person to another, people at most risk are the elderly, the very young, pregnant women and those whose health is already compromised. The adjacent chart shows that the level of CO present over a period of time increases the %COHb and that Ei CO alarms respond well before a dangerous %COHb level is reached. However, it should be noted that people with heart disease and other associated illnesses may suffer harmful effects even at low COHb levels.

4