MAINTENANCE

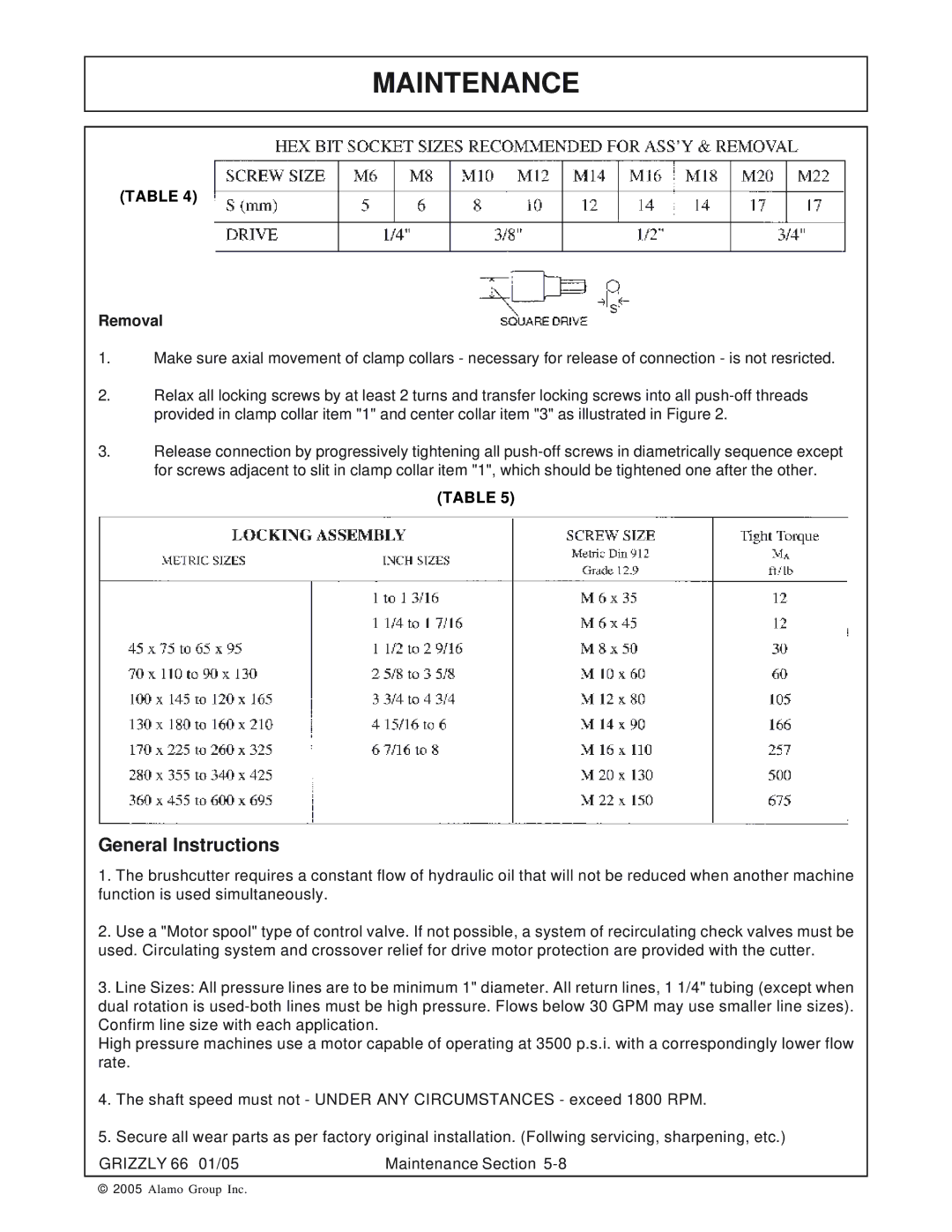

(TABLE 4)

Removal

1.Make sure axial movement of clamp collars - necessary for release of connection - is not resricted.

2.Relax all locking screws by at least 2 turns and transfer locking screws into all

3.Release connection by progressively tightening all

(TABLE 5)

General Instructions

1.The brushcutter requires a constant flow of hydraulic oil that will not be reduced when another machine function is used simultaneously.

2.Use a "Motor spool" type of control valve. If not possible, a system of recirculating check valves must be used. Circulating system and crossover relief for drive motor protection are provided with the cutter.

3.Line Sizes: All pressure lines are to be minimum 1" diameter. All return lines, 1 1/4" tubing (except when dual rotation is

High pressure machines use a motor capable of operating at 3500 p.s.i. with a correspondingly lower flow rate.

4.The shaft speed must not - UNDER ANY CIRCUMSTANCES - exceed 1800 RPM.

5.Secure all wear parts as per factory original installation. (Follwing servicing, sharpening, etc.)

GRIZZLY 66 01/05 | Maintenance Section |

© 2005 Alamo Group Inc.