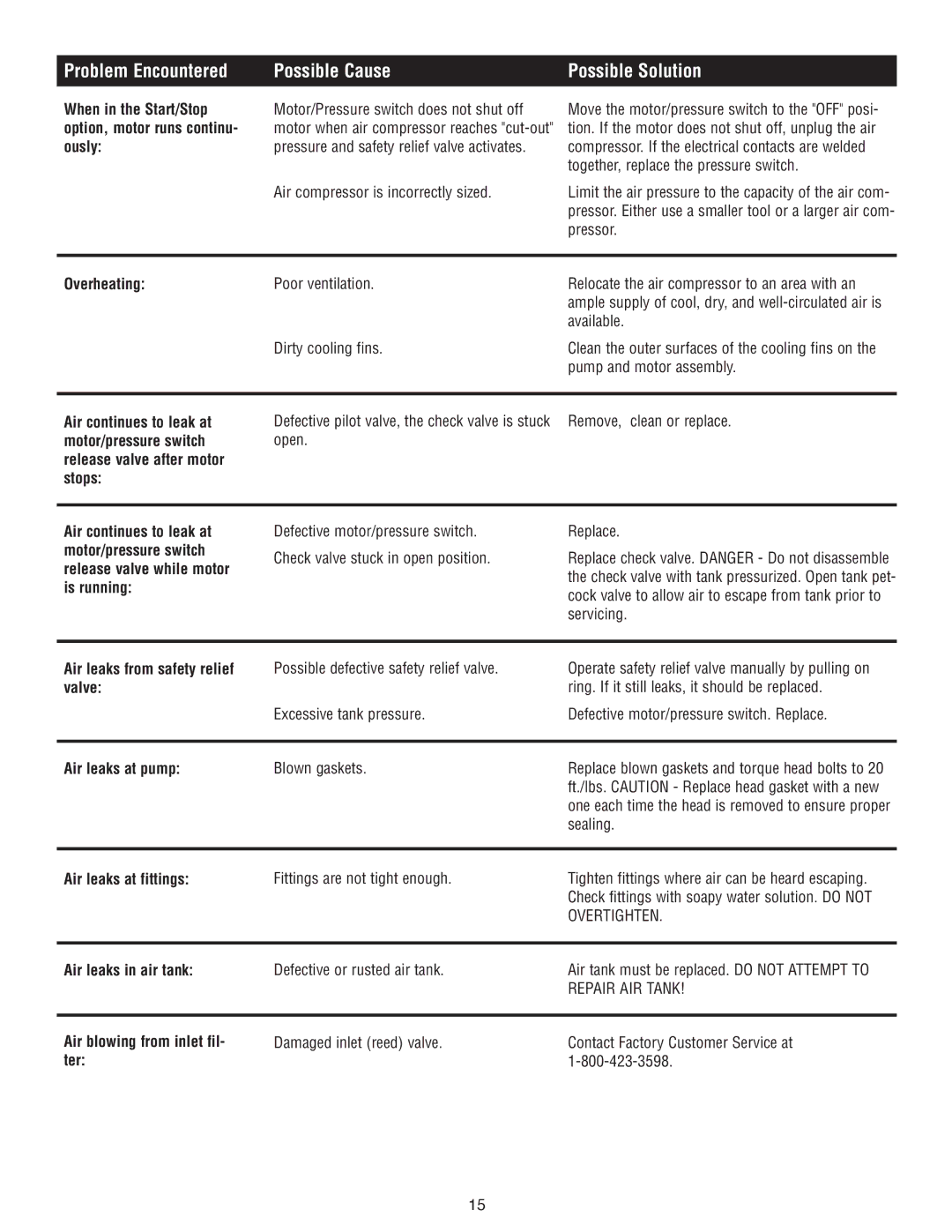

Problem Encountered | Possible Cause | Possible Solution |

|

|

|

When in the Start/Stop option, motor runs continu- ously:

Motor/Pressure switch does not shut off motor when air compressor reaches

Move the motor/pressure switch to the "OFF" posi- tion. If the motor does not shut off, unplug the air compressor. If the electrical contacts are welded together, replace the pressure switch.

Air compressor is incorrectly sized.

Limit the air pressure to the capacity of the air com- pressor. Either use a smaller tool or a larger air com- pressor.

Overheating: | Poor ventilation. | Relocate the air compressor to an area with an |

|

| ample supply of cool, dry, and |

|

| available. |

| Dirty cooling fins. | Clean the outer surfaces of the cooling fins on the |

|

| pump and motor assembly. |

|

|

|

Air continues to leak at motor/pressure switch release valve after motor stops:

Defective pilot valve, the check valve is stuck Remove, clean or replace. open.

Air continues to leak at motor/pressure switch release valve while motor is running:

Defective motor/pressure switch. | Replace. |

Check valve stuck in open position. | Replace check valve. DANGER - Do not disassemble |

| the check valve with tank pressurized. Open tank pet- |

| cock valve to allow air to escape from tank prior to |

| servicing. |

Air leaks from safety relief | Possible defective safety relief valve. | Operate safety relief valve manually by pulling on |

valve: |

| ring. If it still leaks, it should be replaced. |

| Excessive tank pressure. | Defective motor/pressure switch. Replace. |

|

|

|

Air leaks at pump: | Blown gaskets. | Replace blown gaskets and torque head bolts to 20 |

|

| ft./lbs. CAUTION - Replace head gasket with a new |

|

| one each time the head is removed to ensure proper |

|

| sealing. |

|

|

|

Air leaks at fittings: | Fittings are not tight enough. |

Tighten fittings where air can be heard escaping. Check fittings with soapy water solution. DO NOT OVERTIGHTEN.

Air leaks in air tank: | Defective or rusted air tank. |

Air tank must be replaced. DO NOT ATTEMPT TO REPAIR AIR TANK!

Air blowing from inlet fil- | Damaged inlet (reed) valve. | Contact Factory Customer Service at |

ter: |

|

15