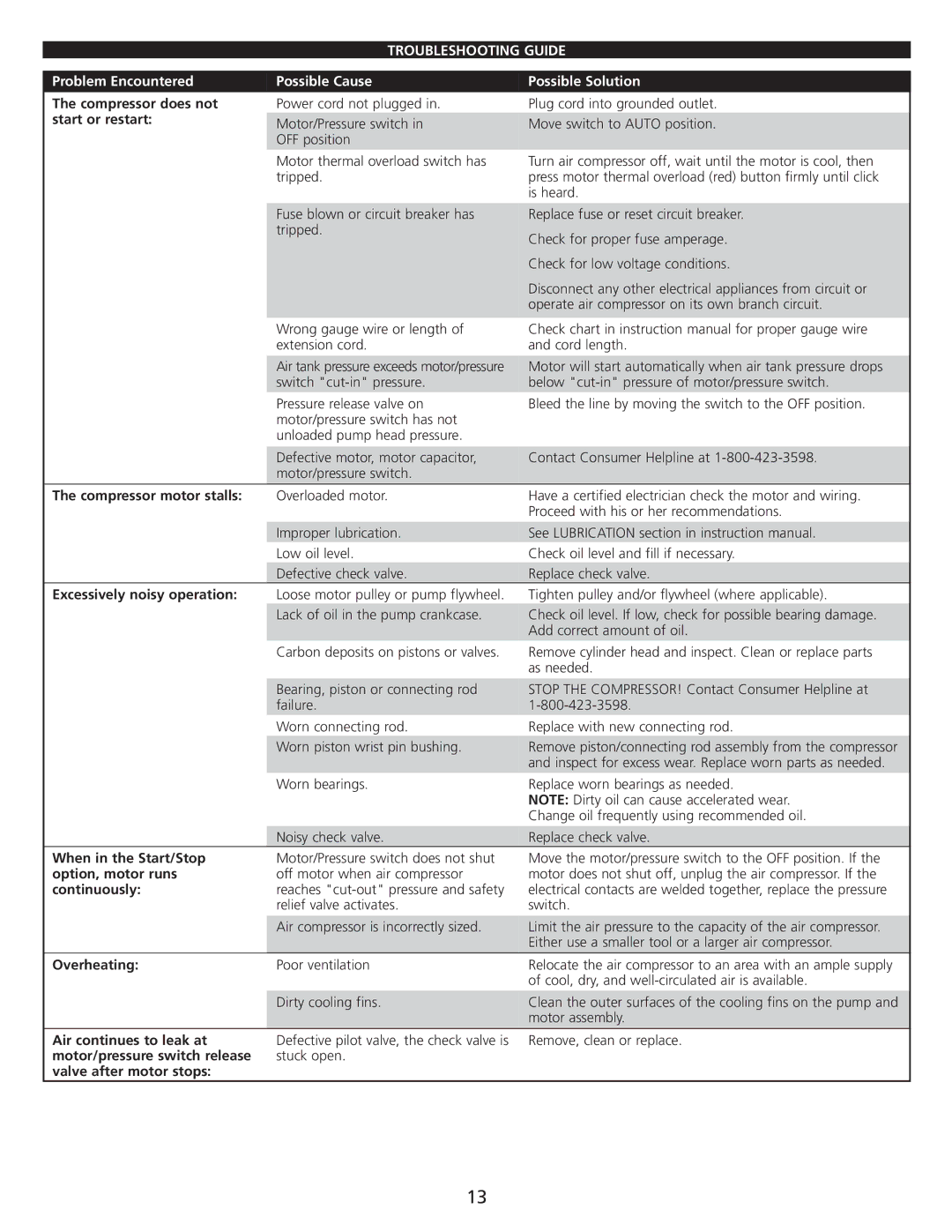

| TROUBLESHOOTING GUIDE | |

|

|

|

Problem Encountered | Possible Cause | Possible Solution |

The compressor does not | Power cord not plugged in. | Plug cord into grounded outlet. |

start or restart: | Motor/Pressure switch in | Move switch to AUTO position. |

| ||

OFF position

Motor thermal overload switch has tripped.

Turn air compressor off, wait until the motor is cool, then press motor thermal overload (red) button firmly until click is heard.

| Fuse blown or circuit breaker has | Replace fuse or reset circuit breaker. |

| tripped. | Check for proper fuse amperage. |

|

| |

|

| Check for low voltage conditions. |

|

| Disconnect any other electrical appliances from circuit or |

|

| operate air compressor on its own branch circuit. |

|

|

|

| Wrong gauge wire or length of | Check chart in instruction manual for proper gauge wire |

| extension cord. | and cord length. |

|

|

|

| Air tank pressure exceeds motor/pressure | Motor will start automatically when air tank pressure drops |

| switch | below |

| Pressure release valve on | Bleed the line by moving the switch to the OFF position. |

| motor/pressure switch has not |

|

| unloaded pump head pressure. |

|

|

|

|

| Defective motor, motor capacitor, | Contact Consumer Helpline at |

| motor/pressure switch. |

|

The compressor motor stalls: | Overloaded motor. | Have a certified electrician check the motor and wiring. |

|

| Proceed with his or her recommendations. |

| Improper lubrication. | See LUBRICATION section in instruction manual. |

| Low oil level. | Check oil level and fill if necessary. |

| Defective check valve. | Replace check valve. |

Excessively noisy operation: | Loose motor pulley or pump flywheel. | Tighten pulley and/or flywheel (where applicable). |

| Lack of oil in the pump crankcase. | Check oil level. If low, check for possible bearing damage. |

|

| Add correct amount of oil. |

Carbon deposits on pistons or valves.

Remove cylinder head and inspect. Clean or replace parts as needed.

Bearing, piston or connecting rod | STOP THE COMPRESSOR! Contact Consumer Helpline at |

failure. | |

Worn connecting rod. | Replace with new connecting rod. |

Worn piston wrist pin bushing. | Remove piston/connecting rod assembly from the compressor |

| and inspect for excess wear. Replace worn parts as needed. |

Worn bearings. | Replace worn bearings as needed. |

| NOTE: Dirty oil can cause accelerated wear. |

| Change oil frequently using recommended oil. |

|

|

Noisy check valve. | Replace check valve. |

When in the Start/Stop | Motor/Pressure switch does not shut |

option, motor runs | off motor when air compressor |

continuously: | reaches |

| relief valve activates. |

| Air compressor is incorrectly sized. |

Move the motor/pressure switch to the OFF position. If the motor does not shut off, unplug the air compressor. If the electrical contacts are welded together, replace the pressure switch.

Limit the air pressure to the capacity of the air compressor. Either use a smaller tool or a larger air compressor.

Overheating: | Poor ventilation | Relocate the air compressor to an area with an ample supply |

|

| of cool, dry, and |

| Dirty cooling fins. | Clean the outer surfaces of the cooling fins on the pump and |

|

| motor assembly. |

|

|

|

Air continues to leak at motor/pressure switch release valve after motor stops:

Defective pilot valve, the check valve is Remove, clean or replace. stuck open.

13