Detector Switches

Soldering Conditions

Soldering Conditions

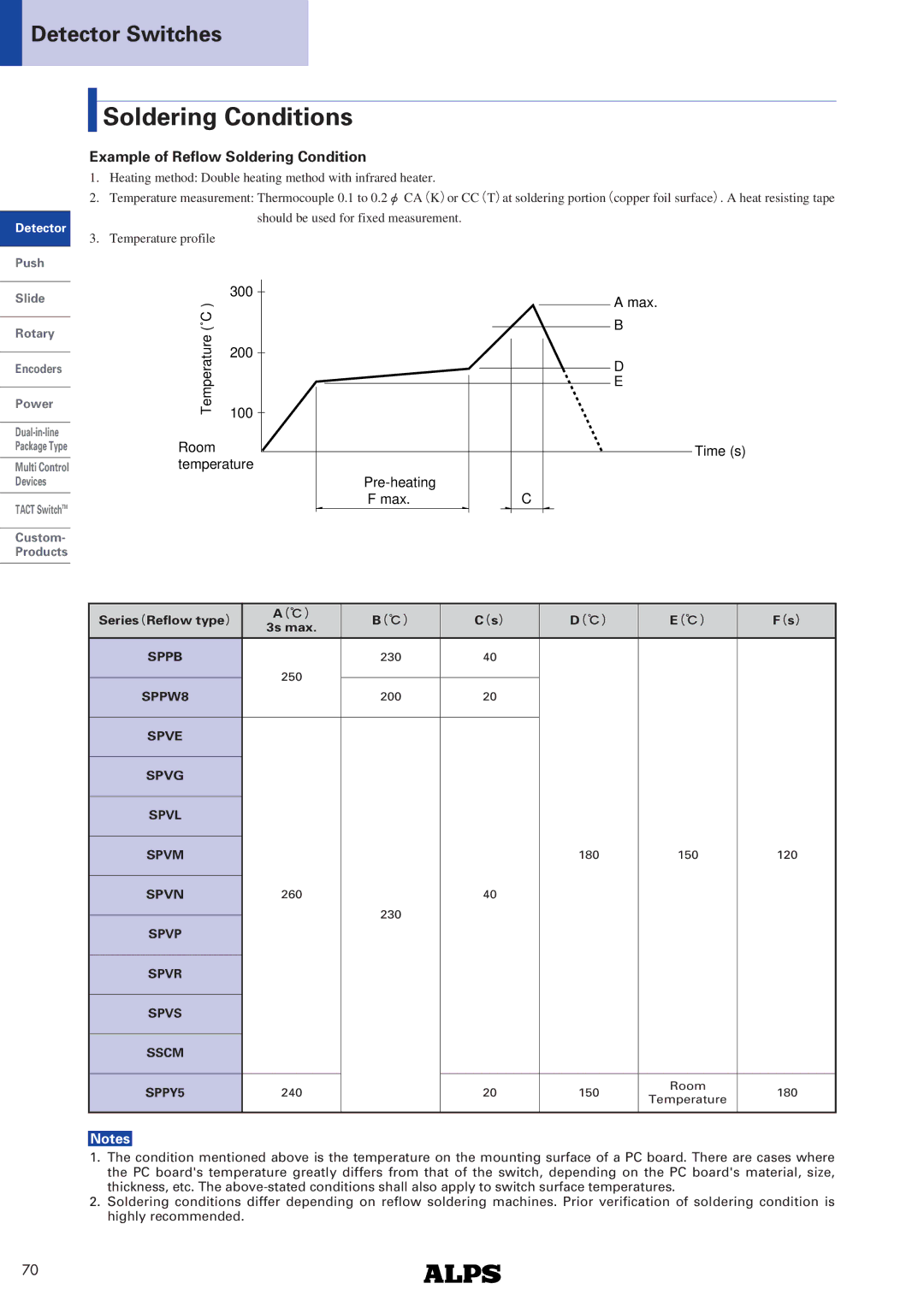

Example of Reflow Soldering Condition

1.Heating method: Double heating method with infrared heater.

2.Temperature measurement: Thermocouple 0.1 to 0.2φ CA(K)or CC(T)at soldering portion(copper foil surface). A heat resisting tape should be used for fixed measurement.

Detector

3. Temperature profile

Push |

|

|

|

|

Slide |

| 300 |

| A max. |

) |

|

| ||

Rotary | (˚C |

|

| B |

Temperature |

|

|

| |

| 200 |

| D | |

|

|

| ||

Encoders |

|

|

| |

|

|

|

| E |

Power |

| 100 |

|

|

|

|

|

| |

|

|

|

| |

Package Type | Room |

|

| Time (s) |

Multi Control | temperature |

|

| |

Devices |

|

|

| |

TACT SwitchTM |

|

| F max. | C |

|

|

|

| |

Custom- |

|

|

|

|

Products |

|

|

|

|

Series(Reflow type) | A(℃) | B(℃) | C(s) | D(℃) | E(℃) | F(s) | |

3s max. | |||||||

|

|

|

|

|

| ||

SPPB |

| 230 | 40 |

|

|

| |

| 250 |

|

|

|

|

| |

SPPW8 | 200 | 20 |

|

|

| ||

|

|

|

| ||||

|

|

|

|

|

|

| |

SPVE |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

SPVG |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

SPVL |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

SPVM |

|

|

| 180 | 150 | 120 | |

|

|

|

|

|

|

| |

SPVN | 260 |

| 40 |

|

|

| |

|

| 230 |

|

|

|

| |

SPVP |

|

|

|

|

| ||

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

SPVR |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

SPVS |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

SSCM |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

SPPY5 | 240 |

| 20 | 150 | Room | 180 | |

| Temperature | ||||||

|

|

|

|

|

| ||

|

|

|

|

|

|

|

Notes

1.The condition mentioned above is the temperature on the mounting surface of a PC board. There are cases where the PC board's temperature greatly differs from that of the switch, depending on the PC board's material, size, thickness, etc. The

2.Soldering conditions differ depending on reflow soldering machines. Prior verification of soldering condition is highly recommended.

70