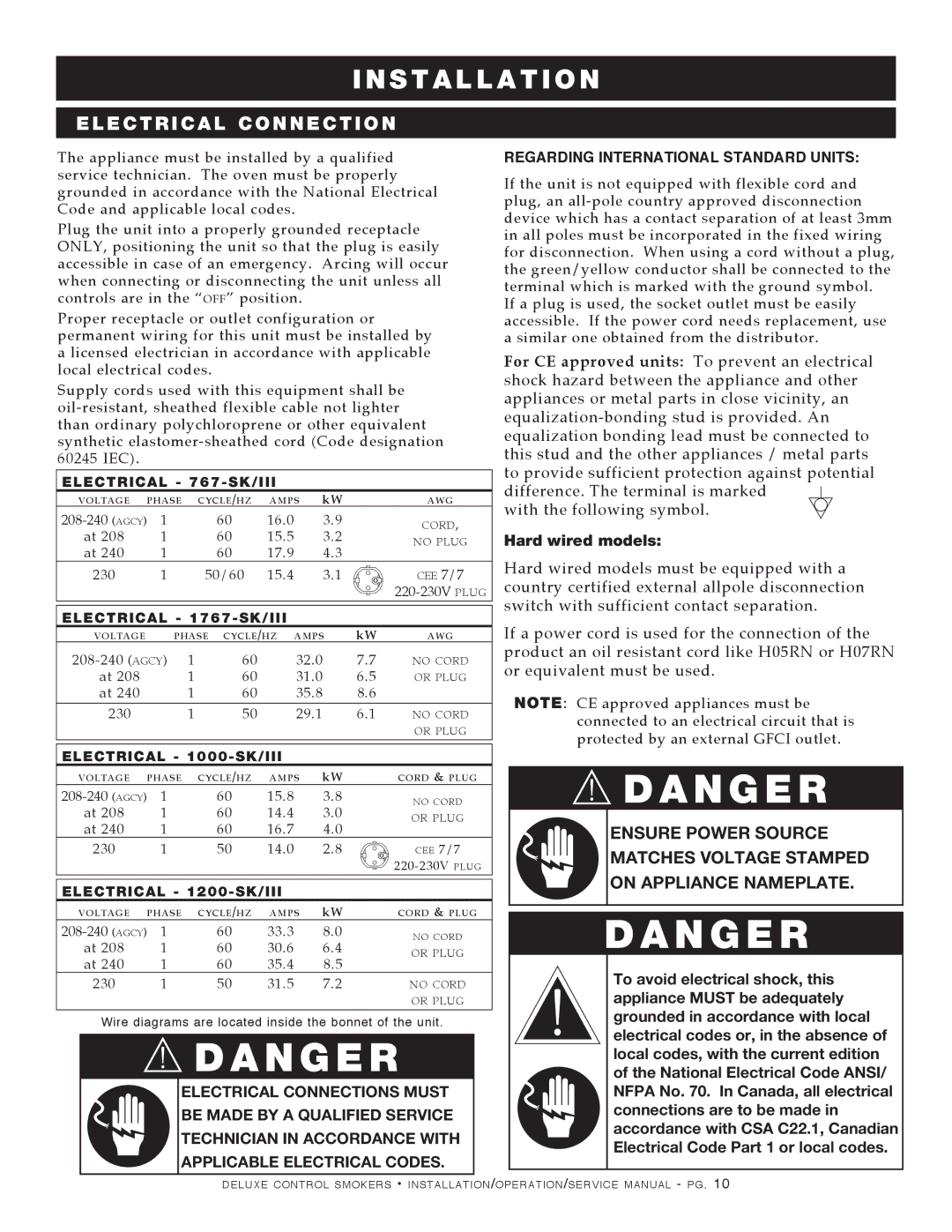

1000-SK/III, 1200-SK/III specifications

Alto-Shaam 1200-SK/III and 1000-SK/III are innovative cooking solutions designed for food service operations seeking efficiency, versatility, and quality. These heated holding cabinets are uniquely constructed to manage food temperature and quality, ensuring that meals remain hot and fresh for extended periods without compromising taste or texture.One of the standout features of the Alto-Shaam 1200-SK/III is its patented Halo Heat technology. This technology provides consistent heat distribution throughout the cabinet, minimizing the risk of overcooking or drying out food. Halo Heat creates a gentle, even warmth that preserves food quality by maintaining the natural moisture levels. Additionally, it eliminates the need for water pans, simplifying the operating process and reducing maintenance tasks.

On the other hand, the 1000-SK/III model showcases similar capabilities but in a more compact size, making it ideal for establishments with limited space. Both models are designed with a digital control panel that allows for precise temperature adjustments from 80°F to 200°F, accommodating various food holding requirements and settings. This control feature not only streamlines operation but also enhances user experience, making it easy to monitor and maintain optimal food temperatures.

The construction of both models emphasizes durability and ease of use. They are built with stainless steel exteriors and interiors, ensuring long-lasting performance and easy cleaning. The accessibility of the interior space also allows for convenient loading and unloading of food pans, enhancing workflow in busy kitchen environments.

Energy efficiency is another important characteristic of the Alto-Shaam 1200-SK/III and 1000-SK/III. They are designed to consume less electricity while delivering exceptional performance. This not only helps businesses save on energy costs but also aligns with the growing emphasis on sustainability within the food service industry.

In summary, the Alto-Shaam 1200-SK/III and 1000-SK/III boast an array of essential features including innovative Halo Heat technology, adjustable temperature controls, durable construction, and energy efficiency. Together, these models provide a reliable solution for food service operators looking to maintain the integrity of their dishes while enhancing overall operational efficiency. Whether for high-capacity operations or smaller kitchens, these heated holding cabinets are valuable assets in delivering high-quality dining experiences.