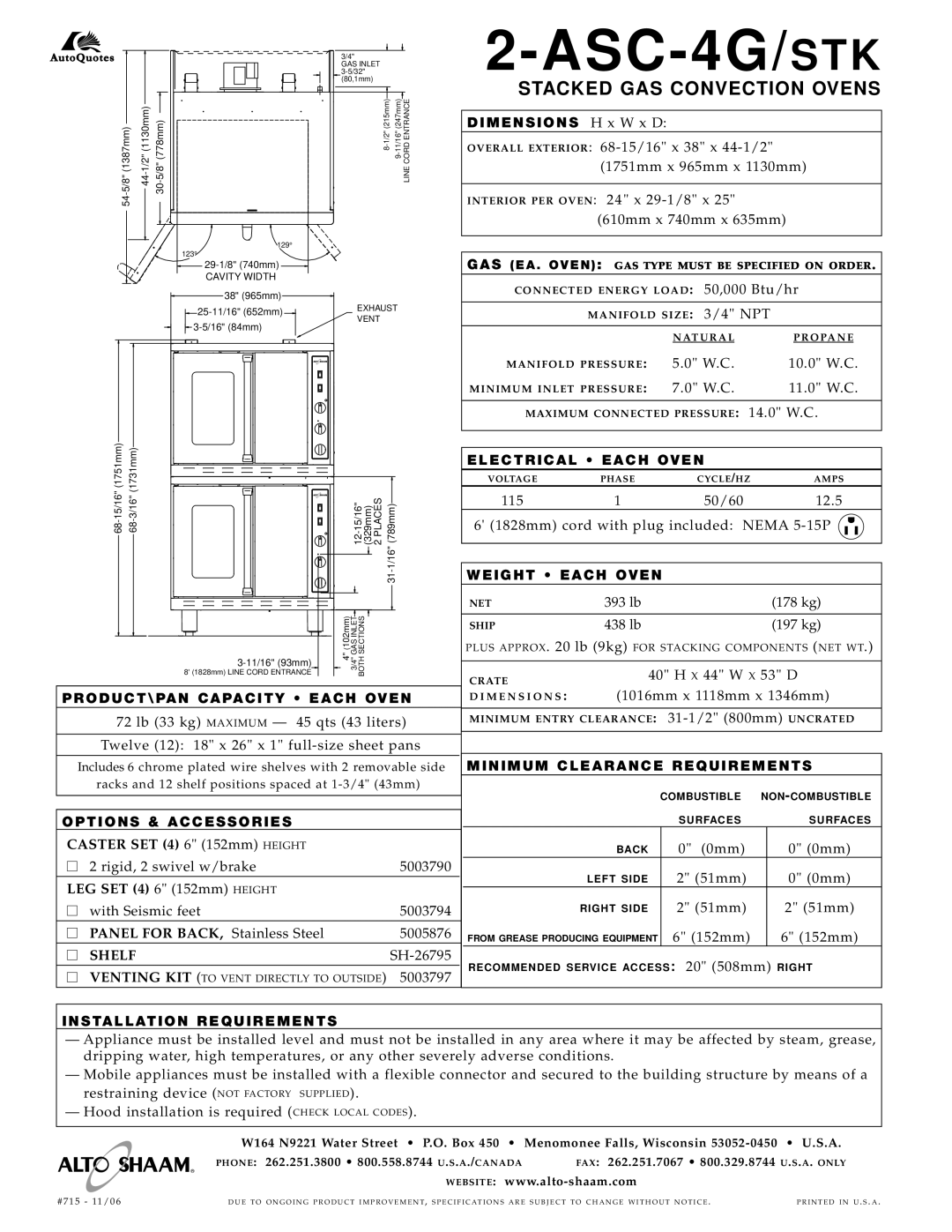

2-ASC-4G/STK specifications

The Alto-Shaam 2-ASC-4G/STK is a versatile and innovative cooking solution designed for commercial kitchens that prioritize efficiency, consistency, and quality. This unit exemplifies state-of-the-art technology, making it an essential asset for restaurants, hotels, and catering services.One of the main features of the Alto-Shaam 2-ASC-4G/STK is its advanced multi-cook technology. This allows operators to prepare a variety of dishes simultaneously, each at different temperatures and cooking times. The unit is equipped with four distinct cooking chambers, enabling chefs to maximize workflow and minimize the wait time for customers. This feature is particularly beneficial during peak service hours, boosting productivity in high-volume environments.

The cooking technology employed by the Alto-Shaam 2-ASC-4G/STK includes a combination of convection and steam modes, providing operators the flexibility to choose the best cooking method for each dish. The steam mode enhances moisture retention, making it ideal for delicate items like fish and vegetables, while the convection mode ensures even browning and crisping for baked goods and roasted meats. This dual functionality simplifies preparation processes and broadens menu options.

Another key characteristic of the Alto-Shaam 2-ASC-4G/STK is its user-friendly digital control panel. This system enables precise temperature control and allows for programming of cooking cycles, reducing the risk of human error in busy kitchens. Chefs can easily monitor and adjust cooking parameters, ensuring that every dish meets exact specifications. Additionally, the programmable settings facilitate consistency across multiple service periods, vital for maintaining high quality and customer satisfaction.

Energy efficiency is a highlighted feature of the Alto-Shaam 2-ASC-4G/STK. The unit is designed to minimize energy consumption without compromising performance, making it more environmentally friendly and cost-effective. This translates into significant savings on utility bills over time, adding value to the kitchen operation.

In terms of design, the Alto-Shaam 2-ASC-4G/STK is constructed from durable stainless steel, ensuring longevity and resistance to wear and tear in a demanding kitchen environment. Its compact design makes it an excellent choice for establishments with limited space, while still providing ample cooking capacity.

Overall, the Alto-Shaam 2-ASC-4G/STK stands out in the commercial kitchen landscape for its advanced features, innovative technologies, and high-quality construction, making it an indispensable tool for modern culinary operations.