4.Mark screw positions for front and rear connectors and

tape ¼" from drill tip to set drilling depth. Use care not to drill through tabletop.

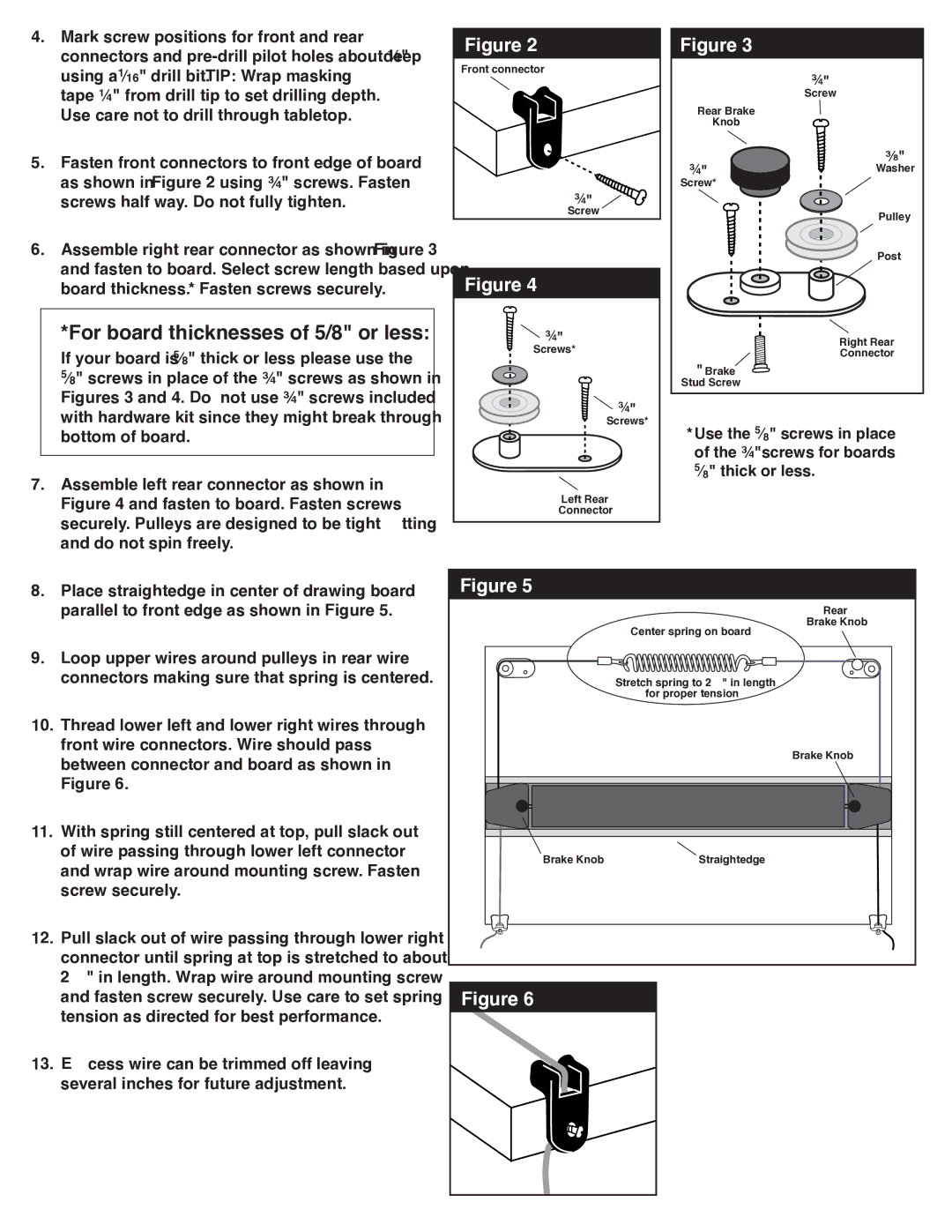

5.Fasten front connectors to front edge of board as shown in Figure 2 using ¾" screws. Fasten screws half way. Do not fully tighten.

6.Assemble right rear connector as shown in Figure 3 and fasten to board. Select screw length based upon board thickness.* Fasten screws securely.

*For board thicknesses of 5/8" or less:

If your board is 5⁄8" thick or less please use the

5⁄8" screws in place of the ¾" screws as shown in Figures 3 and 4. Do not use ¾" screws included with hardware kit since they might break through bottom of board.

7.Assemble left rear connector as shown in Figure 4 and fasten to board. Fasten screws securely. Pulleys are designed to be tight fitting and do not spin freely.

Figure 2

Front connector

¾"

Screw

Figure 4

![]()

![]() ¾"

¾"

Screws*

![]()

![]() ¾"

¾"

Screws*

Left Rear

Connector

Figure 3

| ¾" |

| Screw |

Rear Brake |

|

Knob |

|

¾" | 3⁄8" |

Washer | |

Screw* |

|

| Pulley |

| Post |

Right Rear

Connector

½" Brake

Stud Screw

*Use the 5⁄8" screws in place of the ¾"screws for boards 5⁄8" thick or less.

8. | Place straightedge in center of drawing board |

| parallel to front edge as shown in Figure 5. |

9. | Loop upper wires around pulleys in rear wire |

| connectors making sure that spring is centered. |

Figure 5

Center spring on board

Rear

Brake Knob

10. | Thread lower left and lower right wires through |

| front wire connectors. Wire should pass |

| between connector and board as shown in |

| Figure 6. |

11. | With spring still centered at top, pull slack out |

| of wire passing through lower left connector |

| and wrap wire around mounting screw. Fasten |

| screw securely. |

12. | Pull slack out of wire passing through lower right |

| connector until spring at top is stretched to about |

| 2½" in length. Wrap wire around mounting screw |

| and fasten screw securely. Use care to set spring |

| tension as directed for best performance. |

13. | Excess wire can be trimmed off leaving |

| several inches for future adjustment. |

Stretch spring to 2½" in length

for proper tension

Brake Knob

Brake Knob | Straightedge |

Figure 6