INSTRUCTIONS & RECOMMENDATIONS

FOR SAFE USE OF LARGE DIAMETER AND ASSEMBLY TYPE ROUTER BITS

THANK YOU FOR PURCHASING ANOTHER

1. Routers Only | Router bits are designed to use in portable or stationary routing machines |

only. Do not use router bits in any other equipment such as drill press, | |

| portable electric drill, cordless drill, die grinder, milling machine, etc. |

8. | Router Table |

9. | Start up |

10. | Vibration |

11. Power Off | |

Where applicable, it is recommended that you use a high quality router table. This is especially useful and safer for panel raising, stile & rail door cutting, etc. Except when securely fastened to a sturdy,

Never start nor stop the router while the cutting tool is touching anything, including the workpiece.

If there is any indication of vibration, immediately turn off and unplug the router and carefully inspect the router, spindle, collet, cutting tool, table, clamps, etc. Do not proceed until the condition has been properly identified and corrected.

Unplug router and or machine before changing tooling.

2. Inspection |

You should always inspect any cutting tool (new or used) before using. Ensure that all hardware (allen screws, hex nuts, collars, etc.) are properly tightened and that ball bearings (if so equipped) rotate freely. Do not use any cutting tool if there is evidence that the carbide is chipped or cracked or if the tool appears imbalanced. This procedure is especially important after

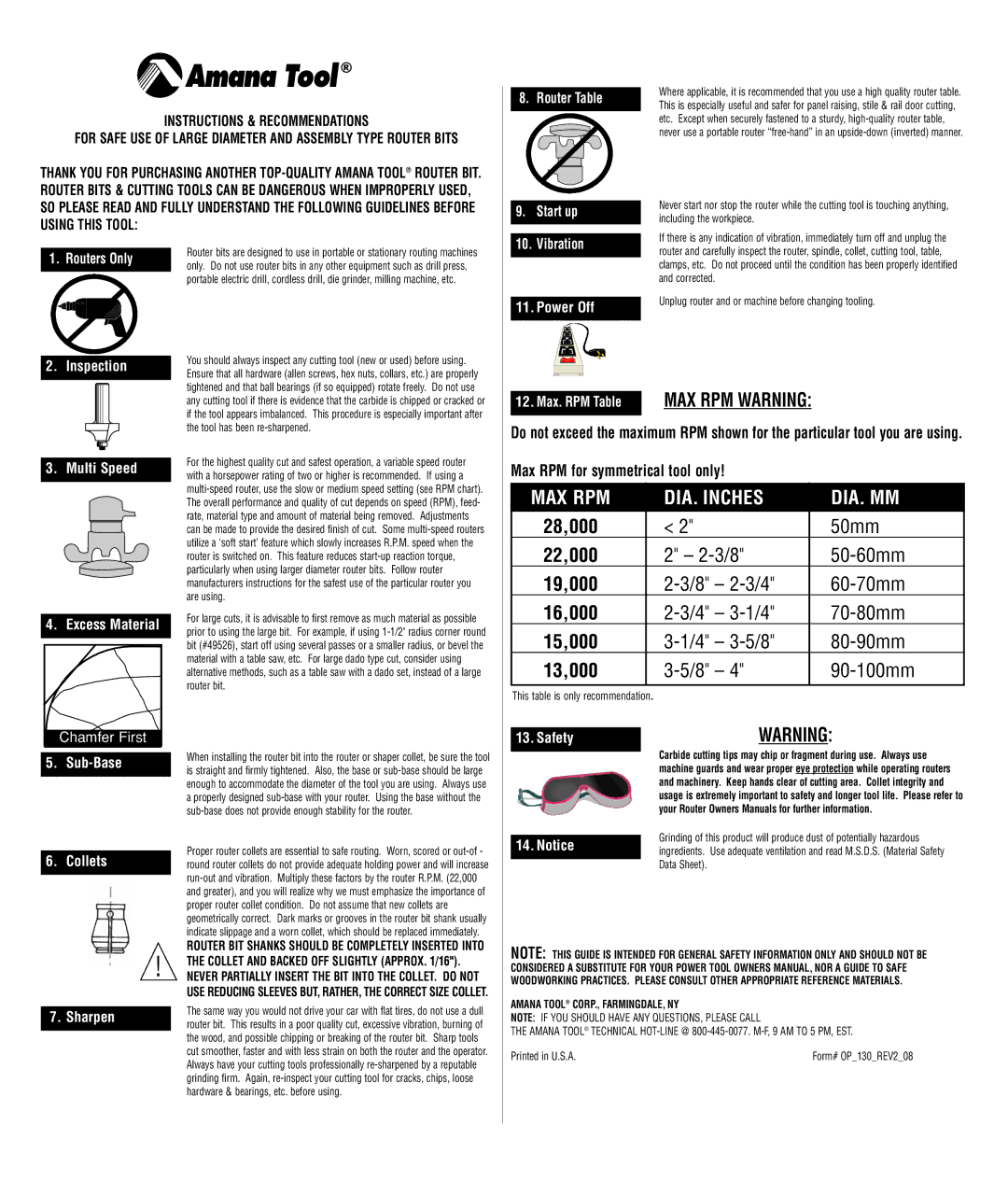

12. Max. RPM Table |

MAX RPM WARNING:

3. Multi Speed |

4. Excess Material

Chamfer First

5. Sub-Base

the tool has been re-sharpened.

For the highest quality cut and safest operation, a variable speed router with a horsepower rating of two or higher is recommended. If using a

For large cuts, it is advisable to first remove as much material as possible prior to using the large bit. For example, if using

When installing the router bit into the router or shaper collet, be sure the tool is straight and firmly tightened. Also, the base or

Do not exceed the maximum RPM shown for the particular tool you are using.

Max RPM for symmetrical tool only!

MAX RPM | DIA. INCHES | DIA. MM |

28,000 | < 2" | 50mm |

22,000 | 2" – | |

19,000 | ||

16,000 | ||

15,000 | ||

13,000 |

| |

|

|

|

This table is only recommendation.

13. Safety | WARNING: |

| Carbide cutting tips may chip or fragment during use. Always use |

| machine guards and wear proper eye protection while operating routers |

| and machinery. Keep hands clear of cutting area. Collet integrity and |

| usage is extremely important to safety and longer tool life. Please refer to |

| your Router Owners Manuals for further information. |

Grinding of this product will produce dust of potentially hazardous

Proper router collets are essential to safe routing. Worn, scored or

6. Colletsround router collets do not provide adequate holding power and will increase

ROUTER BIT SHANKS SHOULD BE COMPLETELY INSERTED INTO

!THE COLLET AND BACKED OFF SLIGHTLY (APPROX. 1/16").

NEVER PARTIALLY INSERT THE BIT INTO THE COLLET. DO NOT USE REDUCING SLEEVES BUT,RATHER, THE CORRECT SIZE COLLET.

7. Sharpen | The same way you would not drive your car with flat tires, do not use a dull | |

router bit. This results in a poor quality cut, excessive vibration, burning of | ||

| ||

| the wood, and possible chipping or breaking of the router bit. Sharp tools | |

| cut smoother, faster and with less strain on both the router and the operator. | |

| Always have your cutting tools professionally | |

| grinding firm. Again, | |

| hardware & bearings, etc. before using. |

14. Noticeingredients. Use adequate ventilation and read M.S.D.S. (Material Safety Data Sheet).

NOTE: THIS GUIDE IS INTENDED FOR GENERAL SAFETY INFORMATION ONLY AND SHOULD NOT BE CONSIDERED A SUBSTITUTE FOR YOUR POWER TOOL OWNERS MANUAL, NOR A GUIDE TO SAFE WOODWORKING PRACTICES. PLEASE CONSULT OTHER APPROPRIATE REFERENCE MATERIALS.

AMANA TOOL® CORP., FARMINGDALE, NY

NOTE: IF YOU SHOULD HAVE ANY QUESTIONS, PLEASE CALL

THE AMANA TOOL® TECHNICAL

Printed in U.S.A. | Form# OP_130_REV2_08 |