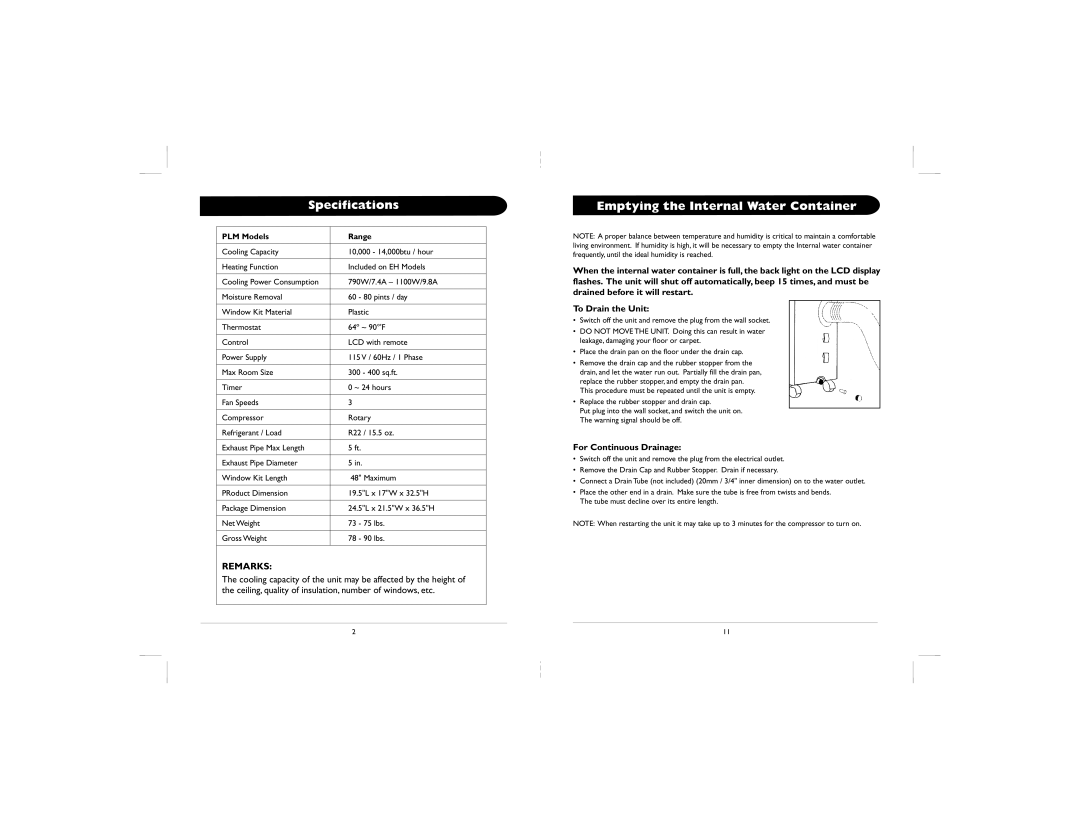

PLM specifications

Amcor PLM (Product Lifecycle Management) is an innovative solution designed specifically for the packaging industry, enabling businesses to efficiently manage their product development processes from inception to retirement. As a leader in global packaging solutions, Amcor leverages this technology to streamline operations, enhance collaboration, and drive sustainability efforts across the supply chain.One of the standout features of Amcor PLM is its ability to centralize product data and documentation. This means that all information related to products, from specifications and designs to compliance documents, can be stored in a single repository. This centralization not only reduces the risk of errors but also improves accessibility, allowing teams to collaborate effectively, regardless of geographical locations.

Amcor PLM is built on advanced cloud-based technologies, providing users with the flexibility to access the system from anywhere at any time. This cloud functionality ensures that real-time updates can be made easily, keeping all stakeholders informed and aligned throughout the product development lifecycle. The intuitive user interface is designed for ease of use, promoting quicker onboarding and adoption among team members.

Another key characteristic of Amcor PLM is its integration capabilities with other enterprise systems such as ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), and CAD (Computer-Aided Design) tools. This integration facilitates seamless data exchange, enabling cross-functional teams to work cohesively. For example, designers can easily share specifications with manufacturing, ensuring that products are produced according to the highest standards.

Amcor PLM also places a strong emphasis on sustainability. The platform includes features that allow users to assess the environmental impacts of their packaging choices. By analyzing materials, manufacturing processes, and end-of-life options, businesses can make informed decisions that align with their sustainability goals.

Additionally, Amcor PLM supports regulatory compliance by offering tools to help businesses navigate the complex landscape of packaging regulations. This functionality is particularly valuable in an era where compliance requirements are constantly evolving.

In conclusion, Amcor PLM stands out as a robust solution for the packaging industry, offering a combination of centralized data management, cloud-based accessibility, integration with existing systems, sustainability assessments, and regulatory compliance support. These features empower companies to innovate and respond rapidly to market demands while maintaining high standards and operational efficiency.