Insert the wiring from the two 120 volt 15 amp circuits (one for top tumbler and one for bottom tumbler) into the strain reliefs.

Determine the top pocket electrical connections by checking wire label, which will be marked “top”.

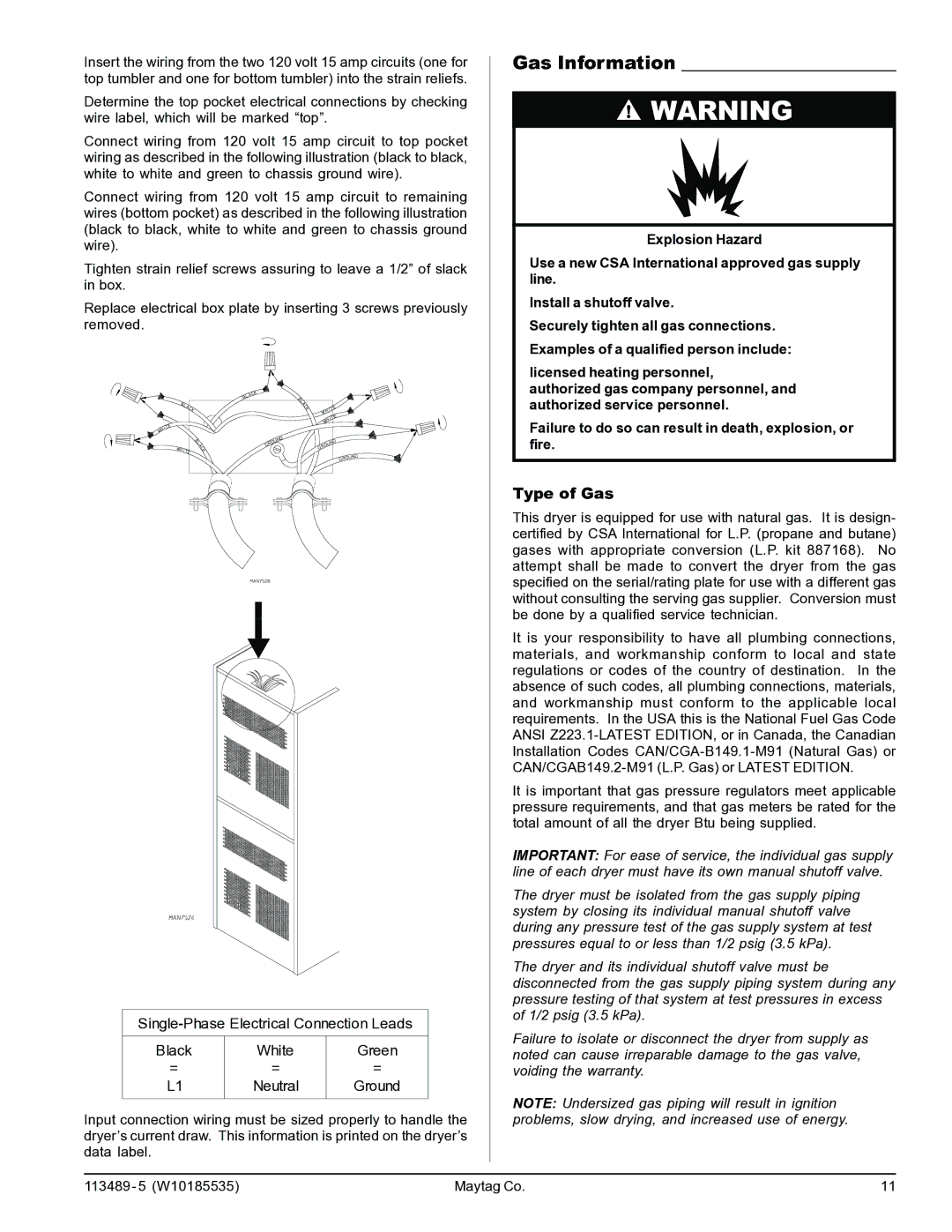

Connect wiring from 120 volt 15 amp circuit to top pocket wiring as described in the following illustration (black to black, white to white and green to chassis ground wire).

Connect wiring from 120 volt 15 amp circuit to remaining wires (bottom pocket) as described in the following illustration (black to black, white to white and green to chassis ground wire).

Tighten strain relief screws assuring to leave a 1/2” of slack in box.

Replace electrical box plate by inserting 3 screws previously removed.

Single-Phase Electrical Connection Leads

Black | White | Green |

= | = | = |

L1 | Neutral | Ground |

|

|

|

Input connection wiring must be sized properly to handle the dryer’s current draw. This information is printed on the dryer’s data label.

Gas Information _______________________

▲! WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shutoff valve.

Securely tighten all gas connections. Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Type of Gas

This dryer is equipped for use with natural gas. It is design- certified by CSA International for L.P. (propane and butane) gases with appropriate conversion (L.P. kit 887168). No attempt shall be made to convert the dryer from the gas specified on the serial/rating plate for use with a different gas without consulting the serving gas supplier. Conversion must be done by a qualified service technician.

It is your responsibility to have all plumbing connections, materials, and workmanship conform to local and state regulations or codes of the country of destination. In the absence of such codes, all plumbing connections, materials, and workmanship must conform to the applicable local requirements. In the USA this is the National Fuel Gas Code ANSI

It is important that gas pressure regulators meet applicable pressure requirements, and that gas meters be rated for the total amount of all the dryer Btu being supplied.

IMPORTANT: For ease of service, the individual gas supply line of each dryer must have its own manual shutoff valve.

The dryer must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure test of the gas supply system at test pressures equal to or less than 1/2 psig (3.5 kPa).

The dryer and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

Failure to isolate or disconnect the dryer from supply as noted can cause irreparable damage to the gas valve, voiding the warranty.

NOTE: Undersized gas piping will result in ignition problems, slow drying, and increased use of energy.

113489 - 5 (W10185535) | Maytag Co. | 11 |