User’s Information

Proper Maintenance

Reduces Energy Use

Oil Supply

•If available, the use of

•DO NOT allow the fuel tank to run completely dry during the heating season. If the fuel tank runs completely dry, it may be necessary to purge the oil lines of trapped air. If necessary, contact a qualified heating dealer to bleed the oil lines and restart the burner.

•During the warmer weather, keep the tank full to prevent condensation of moisture on the inside surface of the tank. The presence of moisture in the tank supports the growth of biologi cal fuel contaminants (bacteria, mold, fungus, yeast, etc.).

•Keep the cap on the fuel tank fill pipe tightly closed at all times to prevent the entrance of moisture, foreign matter, insects, etc. Consider adding a guard or filter to the tank vent pipe to reduce the entrance of water and foreign matter into the tank. Also, check the tank, vent, and fill pipe for cracks and leaks. Have any necessary tank repairs performed as soon as possible.

•Annually, have a bottom sample from the fuel oil tank taken for analysis. If present in excessive quantities, sludge and water should be removed. Fuel oil additives may be of benefit in helping to resolve some problems that are indicated by the analysis. In severe cases, tank cleaning may be required. Consult your fuel oil supplier for recommendations.

A clean filter saves money.

When the furnace circulates and filters the air in your home, dust and dirt particles build up on the filter. Excessive accumulation can block the airflow, forcing the unit to work harder to maintain desired temperatures.

The harder your unit has to work, the more energy it uses. You pay more any time your system is running with a dirty filter.

▲! CAUTION

BURN HAZARD - ROTATING FAN BLADES

To avoid injury from moving parts, hot surfaces, or electri- cal shock, shut off the power to the furnace and allow the furnace to cool BEFORE removing any furnace access doors to service air filters.

▲! CAUTION

Never operate your unit for either heating or cooling with filters removed.

Help ensure top efficiency by replacing disposable filters once a month.

Replacing your filter.

When replacing your furnace filters, always use the same size and type as originally supplied. Filters are available from your dealer.

▲! WARNING

Disconnect power to unit before removing blower door.

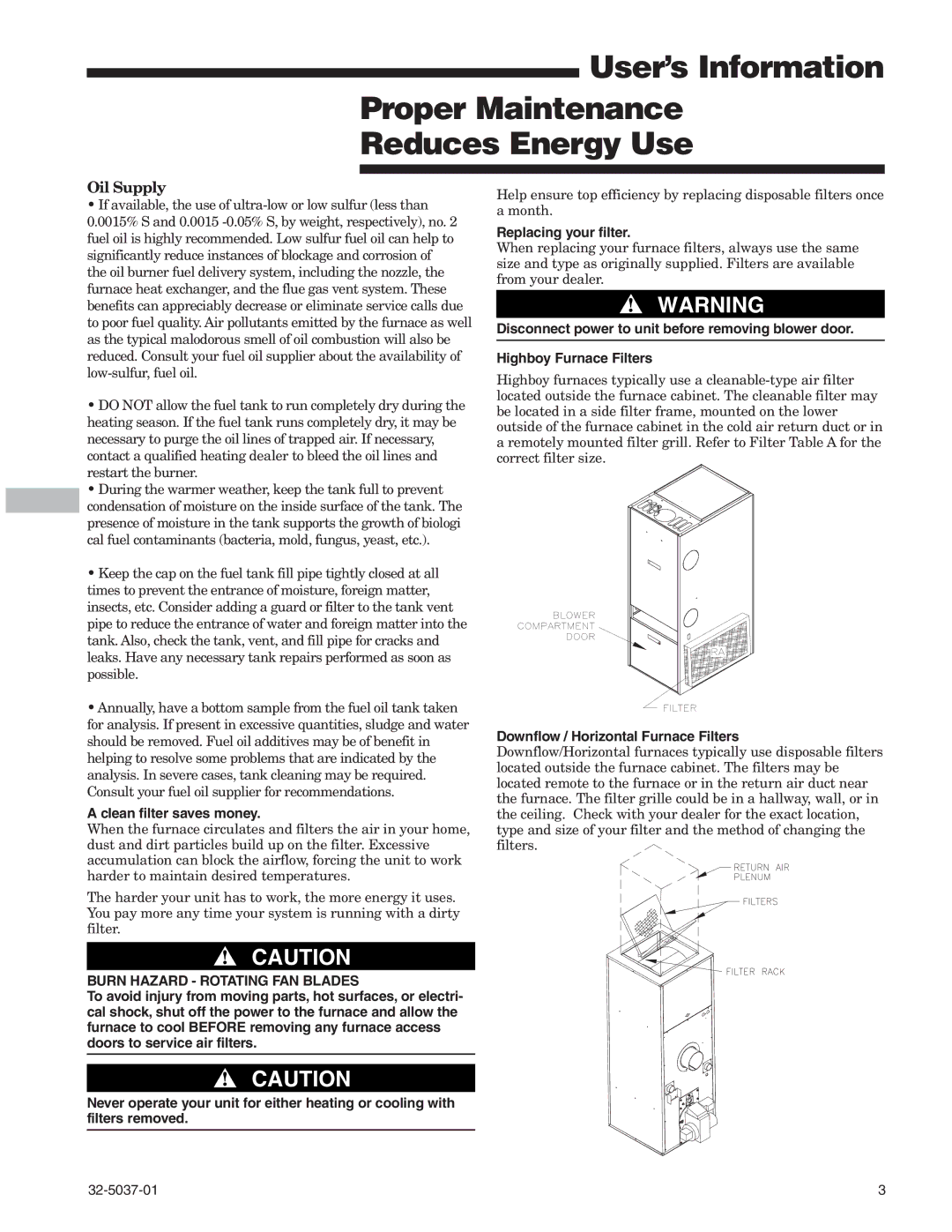

Highboy Furnace Filters

Highboy furnaces typically use a

Downflow / Horizontal Furnace Filters

Downflow/Horizontal furnaces typically use disposable filters located outside the furnace cabinet. The filters may be located remote to the furnace or in the return air duct near the furnace. The filter grille could be in a hallway, wall, or in the ceiling. Check with your dealer for the exact location, type and size of your filter and the method of changing the filters.

3 |