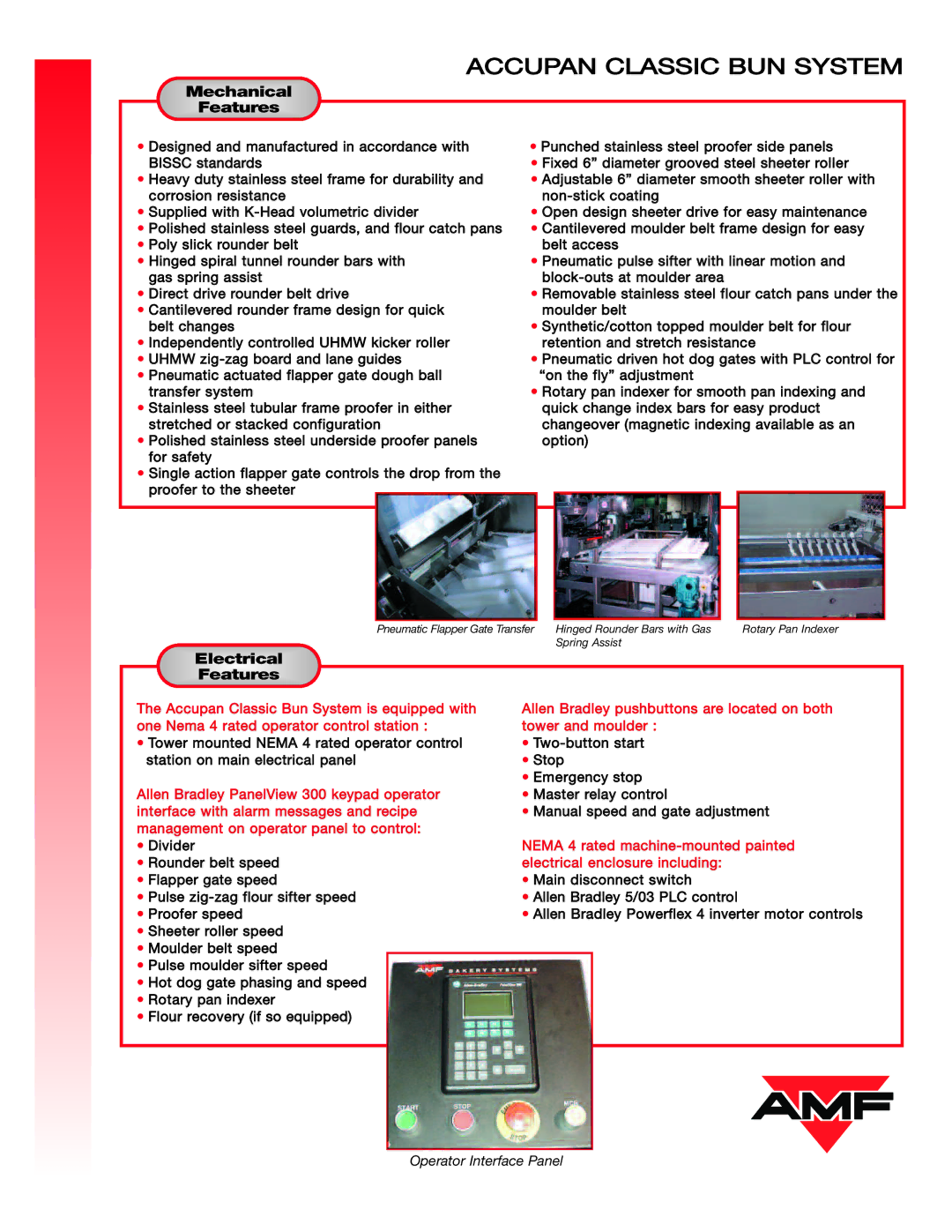

Accupan Classic Bun System specifications

The AMF Accupan Classic Bun System is an innovative solution designed specifically for bakery operations that prioritize efficiency, consistency, and quality. With a focus on automated processes, the system helps streamline production while maintaining the artisanal quality that customers expect from freshly baked goods.One of the standout features of the Accupan Classic Bun System is its precision in dough handling. Utilizing advanced technology, the system ensures uniform dough weights, which is essential for maintaining consistent product quality. It minimizes the manual labor involved in the dough portioning process, thereby reducing the risk of human error. The result is perfectly shaped buns that not only meet but exceed customer expectations.

Another key aspect of the Accupan Classic Bun System is its modular design. This allows bakeries to customize the system according to their specific production needs. Whether the operation is a small bakery or a large-scale production facility, the system can be adapted to fit various workflows. Its compact footprint is particularly advantageous for businesses with limited space, enabling them to maximize efficiency without sacrificing productivity.

The technology behind the AMF Accupan Classic Bun System includes intelligent control systems that monitor and adjust the production process in real-time. This feature enhances operational efficiency by allowing bakers to manage the system remotely. With user-friendly interfaces, operators can easily program production parameters, reducing the training time for staff and allowing for quicker setup between different product types.

Energy efficiency is another significant characteristic of the AMF Accupan Classic Bun System. By minimizing energy consumption during production, bakeries can reduce their operational costs while also contributing to sustainability efforts. The system's design focuses on minimizing waste, both in terms of ingredients and energy, aligning with modern industry standards for environmentally friendly practices.

In summary, the AMF Accupan Classic Bun System is a cutting-edge solution for bakeries aiming to elevate their production capabilities. With features such as precise dough handling, modular adaptability, real-time monitoring, and energy efficiency, it represents a significant advancement in bakery technology. By integrating this system, bakers can achieve high-quality output while optimizing their operations, ultimately contributing to increased profitability and customer satisfaction.