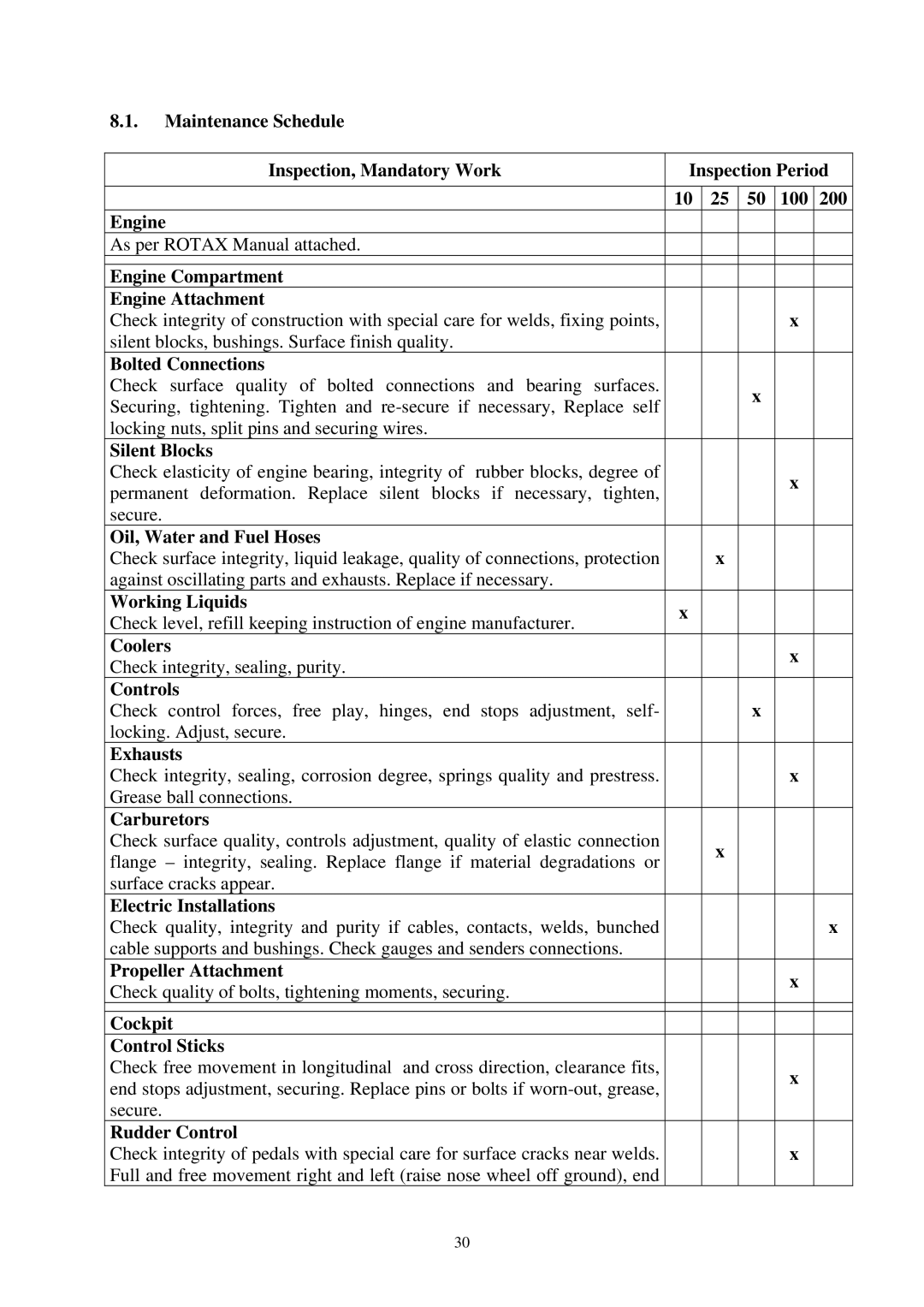

8.1. | Maintenance Schedule |

|

|

|

|

|

|

|

|

|

|

|

|

| Inspection, Mandatory Work | Inspection Period | ||||

|

|

|

|

|

|

|

|

| 10 | 25 | 50 | 100 | 200 |

Engine |

|

|

|

|

| |

As per ROTAX Manual attached. |

|

|

|

|

| |

|

|

|

|

|

| |

Engine Compartment |

|

|

|

|

| |

Engine Attachment |

|

|

| x |

| |

Check integrity of construction with special care for welds, fixing points, |

|

|

|

| ||

silent blocks, bushings. Surface finish quality. |

|

|

|

|

| |

Bolted Connections |

|

|

|

|

| |

Check | surface quality of bolted connections and bearing surfaces. |

|

| x |

|

|

Securing, tightening. Tighten and |

|

|

|

| ||

|

|

|

|

| ||

locking nuts, split pins and securing wires. |

|

|

|

|

| |

Silent Blocks |

|

|

|

|

| |

Check elasticity of engine bearing, integrity of rubber blocks, degree of |

|

|

| x |

| |

permanent deformation. Replace silent blocks if necessary, tighten, |

|

|

|

| ||

|

|

|

|

| ||

secure. |

|

|

|

|

|

|

Oil, Water and Fuel Hoses |

| x |

|

|

| |

Check surface integrity, liquid leakage, quality of connections, protection |

|

|

|

| ||

against oscillating parts and exhausts. Replace if necessary. |

|

|

|

|

| |

Working Liquids | x |

|

|

|

| |

Check level, refill keeping instruction of engine manufacturer. |

|

|

|

| ||

|

|

|

|

| ||

Coolers |

|

|

| x |

| |

Check integrity, sealing, purity. |

|

|

|

| ||

|

|

|

|

| ||

Controls |

|

| x |

|

| |

Check control forces, free play, hinges, end stops adjustment, self- |

|

|

|

| ||

locking. Adjust, secure. |

|

|

|

|

| |

Exhausts |

|

|

| x |

| |

Check integrity, sealing, corrosion degree, springs quality and prestress. |

|

|

|

| ||

Grease ball connections. |

|

|

|

|

| |

Carburetors |

|

|

|

|

| |

Check surface quality, controls adjustment, quality of elastic connection |

| x |

|

|

| |

flange – integrity, sealing. Replace flange if material degradations or |

|

|

|

| ||

|

|

|

|

| ||

surface cracks appear. |

|

|

|

|

| |

Electric Installations |

|

|

|

| x | |

Check quality, integrity and purity if cables, contacts, welds, bunched |

|

|

|

| ||

cable supports and bushings. Check gauges and senders connections. |

|

|

|

|

| |

Propeller Attachment |

|

|

| x |

| |

Check quality of bolts, tightening moments, securing. |

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

|

| |

Cockpit |

|

|

|

|

| |

Control Sticks |

|

|

|

|

| |

Check free movement in longitudinal and cross direction, clearance fits, |

|

|

| x |

| |

end stops adjustment, securing. Replace pins or bolts if |

|

|

|

| ||

|

|

|

|

| ||

secure. |

|

|

|

|

|

|

Rudder Control |

|

|

| x |

| |

Check integrity of pedals with special care for surface cracks near welds. |

|

|

|

| ||

Full and free movement right and left (raise nose wheel off ground), end |

|

|

|

|

| |

30