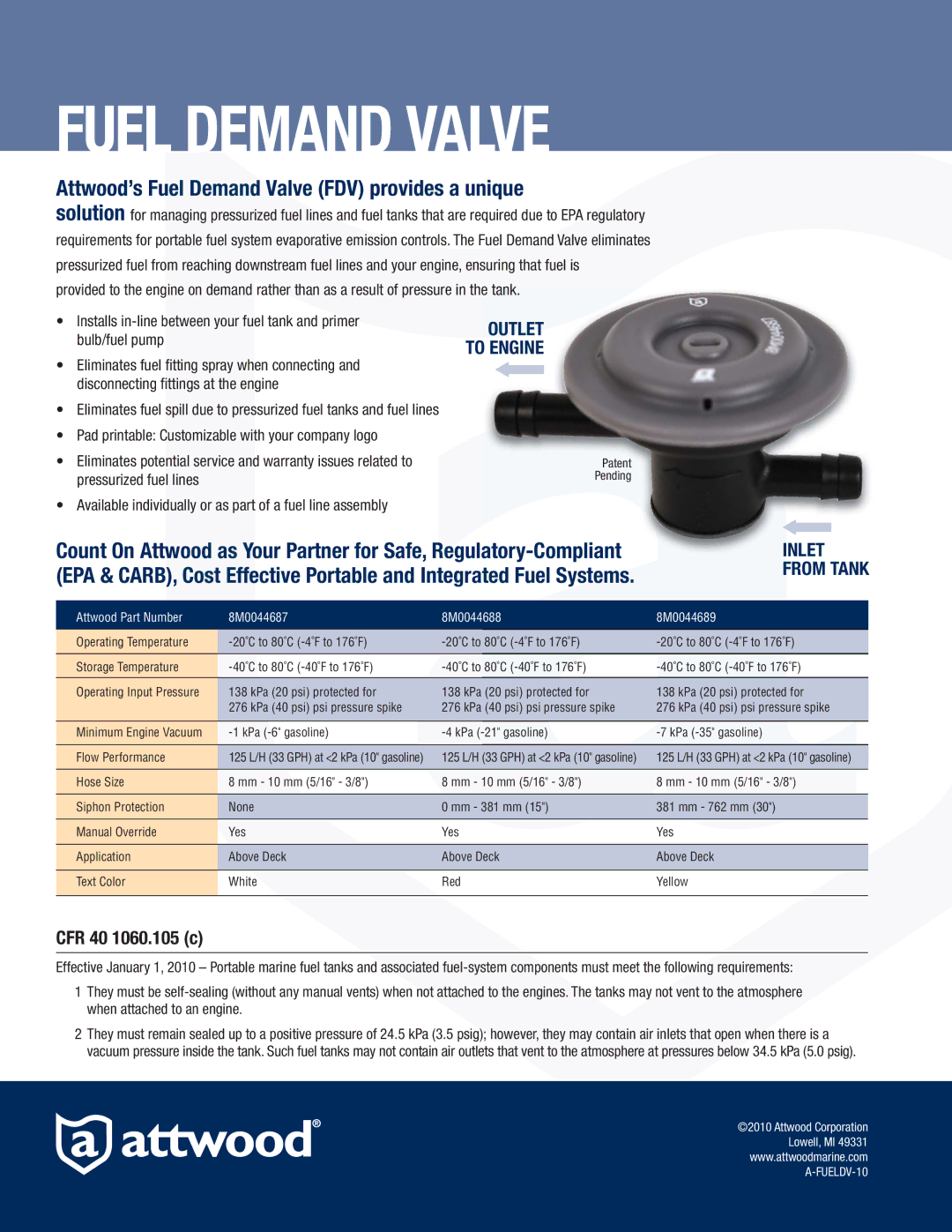

8M0044687, 8M0044688, 8M004689 specifications

The Attwood 8M004689, 8M0044688, and 8M0044687 models are renowned products within the marine industry, each designed to enhance the boating experience through innovative engineering and advanced technology. These models are specifically developed to cater to the needs of boaters, ensuring that both safety and convenience are prioritized.The Attwood 8M004689 serves as a heavy-duty bilge pump, recognized for its reliability and efficiency. It features a powerful motor that provides robust water displacement capability, allowing users to effectively manage bilge water in various boating conditions. A key element of this model is its superior build quality, which includes a corrosion-resistant housing that withstands the harsh marine environment. The automatic operation feature coupled with a built-in float switch ensures that the pump activates only when needed, conserving battery power and extending the lifespan of the pump.

On the other hand, the 8M0044688 is an advanced livewell aerator pump. This model promotes optimal aeration in livewells, helping to maintain a healthy environment for live bait. With a compact design, it fits seamlessly within various boat designs without compromising space. The aerator features a unique dual-chamber technology that maximizes water flow and oxygenation, crucial for keeping bait lively and active while you fish. This model is engineered for quiet operation, minimizing disturbances to the aquatic environment while ensuring the bait is well taken care of.

Lastly, the 8M0044687 model is celebrated for its superior fuel system components, ensuring efficiency in fuel delivery for outboard engines. It utilizes advanced materials and precision engineering to prevent fuel leaks and ensure reliable performance. This model is designed with versatility in mind, making it suitable for a variety of boat types and marine engines. Enhanced filteration systems within the fuel system help to keep the engine clean and running smoothly, which is vital for optimizing performance and extending the engine's life.

In summary, the Attwood 8M004689, 8M0044688, and 8M0044687 products each offer unique features tailored to enhance the boating experience. From efficient bilge pumping to aeration for live bait and superior fuel systems, these models embody durability, performance, and cutting-edge technology necessary for today's boating enthusiasts.