Memory

The

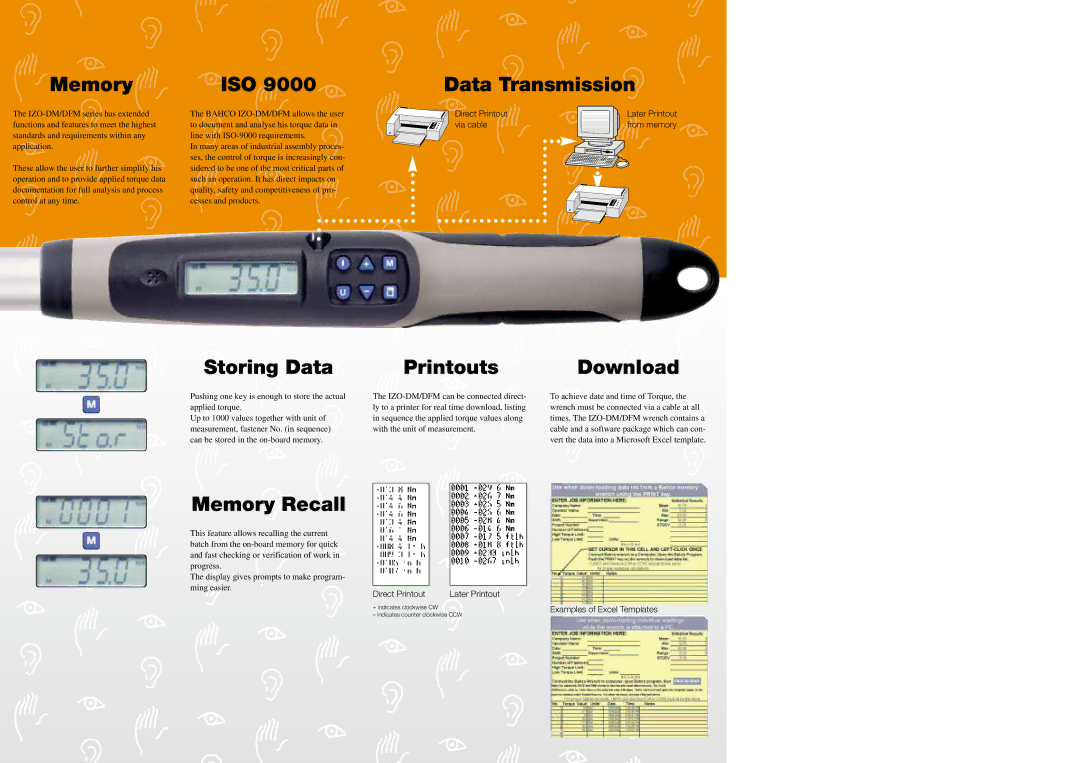

These allow the user to further simplify his operation and to provide applied torque data documentation for full analysis and process control at any time.

ISO 9000 | Data Transmission | |

The BAHCO | Direct Printout | Later Printout |

to document and analyse his torque data in | via cable | from memory |

line with |

|

|

In many areas of industrial assembly proces- |

|

|

ses, the control of torque is increasingly con- |

|

|

sidered to be one of the most critical parts of |

|

|

such an operation. It has direct impacts on |

|

|

quality, safety and competitiveness of pro- |

|

|

cesses and products. |

|

|

Storing Data | Printouts | Download |

Pushing one key is enough to store the actual applied torque.

Up to 1000 values together with unit of measurement, fastener No. (in sequence) can be stored in the

The

To achieve date and time of Torque, the wrench must be connected via a cable at all times. The

Memory Recall

This feature allows recalling the current batch from the

The display gives prompts to make program- ming easier.

Direct Printout | Later Printout |

+ indicates clockwise CW | Examples of Excel Templates |

|

– indicates counter clockwise CCW