MAINTENANCE

For average industrial applications involving 3 or 4 starts a day of not more than 6 seconds acceleration time each, the flow charge should be changed every 10,000 hours of operation. For more severe conditions, visually inspect flow charge at more frequent intervals; it should be changed when it has deteriorated to a half powder, half granular condition. Visual inspections should continue until enough flow charge changes have been made to adequately establish a schedule for renewing FLEXIDYNE flow charge.

The FLEXIDYNE has been lubricated at the factory and no further lubrication is required. Never apply grease, oil or any other foreign material to the flow charge.

OVERLOAD PROTECTION

A Thermal Cutout is available from Dodge and is recommended for FLEXIDYNE Size 9 where slippage (due to overloads, starting or reversing) is frequent or prolonged. Its function is to protect against excessive heat which may be generated by the FLEXIDYNE, A Speed Drop Cutout is available from Dodge for FLEXIDYNE Size 11 for installation where overloads or jamming may occur.

Either unit can be installed to send a signal to interrupt the motor current and, if desired, activate a bell, light or other warning device. Cutout switches are intended for use in control circuits only and are not recommended for dc current nor should they be used directly in the line to the motor. Both units are available in special explosion- proof models for hazardous atmospheres.

THERMAL CAPACITY

Since there is slippage within the flow charge during acceleration, heat is generated from friction. The thermal capacity of the FLEXIDYNE is based on balancing this heat generated during acceleration against the cooling time between accelerations. The amount of heat generated is determined by the amount of horsepower dissipated by slipping and the duration of each acceleration. If the flow charge weight is light, the heat generated will not be as great as that which would be generated with a heavier flow charge, when compared at

the same acceleration time. A longer time between starts will dissipate more heat; therefore, higher starting horsepowers may be transmitted, or longer acceleration times may be allowable. (See Starting Cycle)

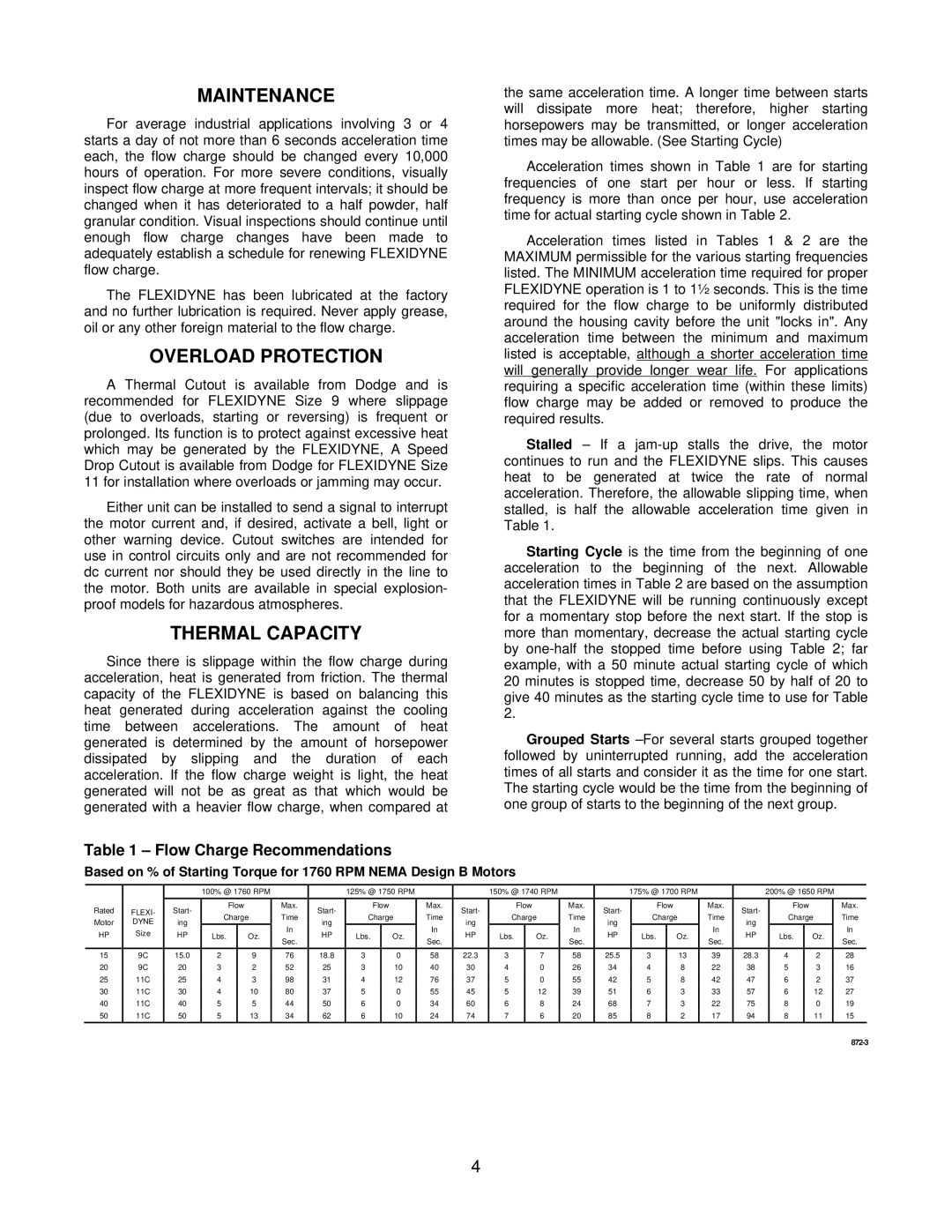

Acceleration times shown in Table 1 are for starting frequencies of one start per hour or less. If starting frequency is more than once per hour, use acceleration time for actual starting cycle shown in Table 2.

Acceleration times listed in Tables 1 & 2 are the MAXIMUM permissible for the various starting frequencies listed. The MINIMUM acceleration time required for proper FLEXIDYNE operation is 1 to 1½ seconds. This is the time required for the flow charge to be uniformly distributed around the housing cavity before the unit "locks in". Any acceleration time between the minimum and maximum listed is acceptable, although a shorter acceleration time will generally provide longer wear life. For applications requiring a specific acceleration time (within these limits) flow charge may be added or removed to produce the required results.

Stalled – If a

Starting Cycle is the time from the beginning of one acceleration to the beginning of the next. Allowable acceleration times in Table 2 are based on the assumption that the FLEXIDYNE will be running continuously except for a momentary stop before the next start. If the stop is more than momentary, decrease the actual starting cycle by

Grouped Starts

Table 1 – Flow Charge Recommendations

Based on % of Starting Torque for 1760 RPM NEMA Design B Motors

|

|

| 100% | @ 1760 RPM |

|

| 125% @ 1750 RPM |

|

| 150% | @ 1740 RPM |

|

| 175% @ 1700 RPM |

|

| 200% @ 1650 RPM |

| ||||||||||||

Rated | FLEXI- | Start- |

|

| Flow | Max. | Start- |

| Flow | Max. | Start- |

|

| Flow | Max. | Start- |

| Flow | Max. | Start- |

| Flow |

|

| Max. | |||||

| Charge | Time | Charge | Time |

| Charge | Time | Charge | Time |

| Charge |

| Time | |||||||||||||||||

Motor | DYNE | ing |

| ing | ing |

| ing | ing |

|

| ||||||||||||||||||||

HP | Size | HP | Lbs. |

| Oz. | In | HP | Lbs. |

| Oz. | In | HP | Lbs. |

| Oz. | In | HP | Lbs. |

| Oz. | In | HP |

| Lbs. |

| Oz. |

| In | ||

| Sec. |

| Sec. |

| Sec. |

| Sec. |

|

|

| Sec. | |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

15 | 9C | 15.0 | 2 |

|

| 9 | 76 | 18.8 | 3 |

| 0 | 58 | 22.3 | 3 |

|

| 7 | 58 | 25.5 | 3 |

| 13 | 39 | 28.3 |

| 4 |

| 2 |

| 28 |

20 | 9C | 20 | 3 |

|

| 2 | 52 | 25 | 3 |

| 10 | 40 | 30 | 4 |

|

| 0 | 26 | 34 | 4 |

| 8 | 22 | 38 |

| 5 |

| 3 |

| 16 |

25 | 11C | 25 | 4 |

|

| 3 | 98 | 31 | 4 |

| 12 | 76 | 37 | 5 |

|

| 0 | 55 | 42 | 5 |

| 8 | 42 | 47 |

| 6 |

| 2 |

| 37 |

30 | 11C | 30 | 4 |

|

| 10 | 80 | 37 | 5 |

| 0 | 55 | 45 | 5 |

|

| 12 | 39 | 51 | 6 |

| 3 | 33 | 57 |

| 6 |

| 12 |

| 27 |

40 | 11C | 40 | 5 |

|

| 5 | 44 | 50 | 6 |

| 0 | 34 | 60 | 6 |

|

| 8 | 24 | 68 | 7 |

| 3 | 22 | 75 |

| 8 |

| 0 |

| 19 |

50 | 11C | 50 | 5 |

|

| 13 | 34 | 62 | 6 |

| 10 | 24 | 74 | 7 |

|

| 6 | 20 | 85 | 8 |

| 2 | 17 | 94 |

| 8 |

| 11 |

| 15 |

4