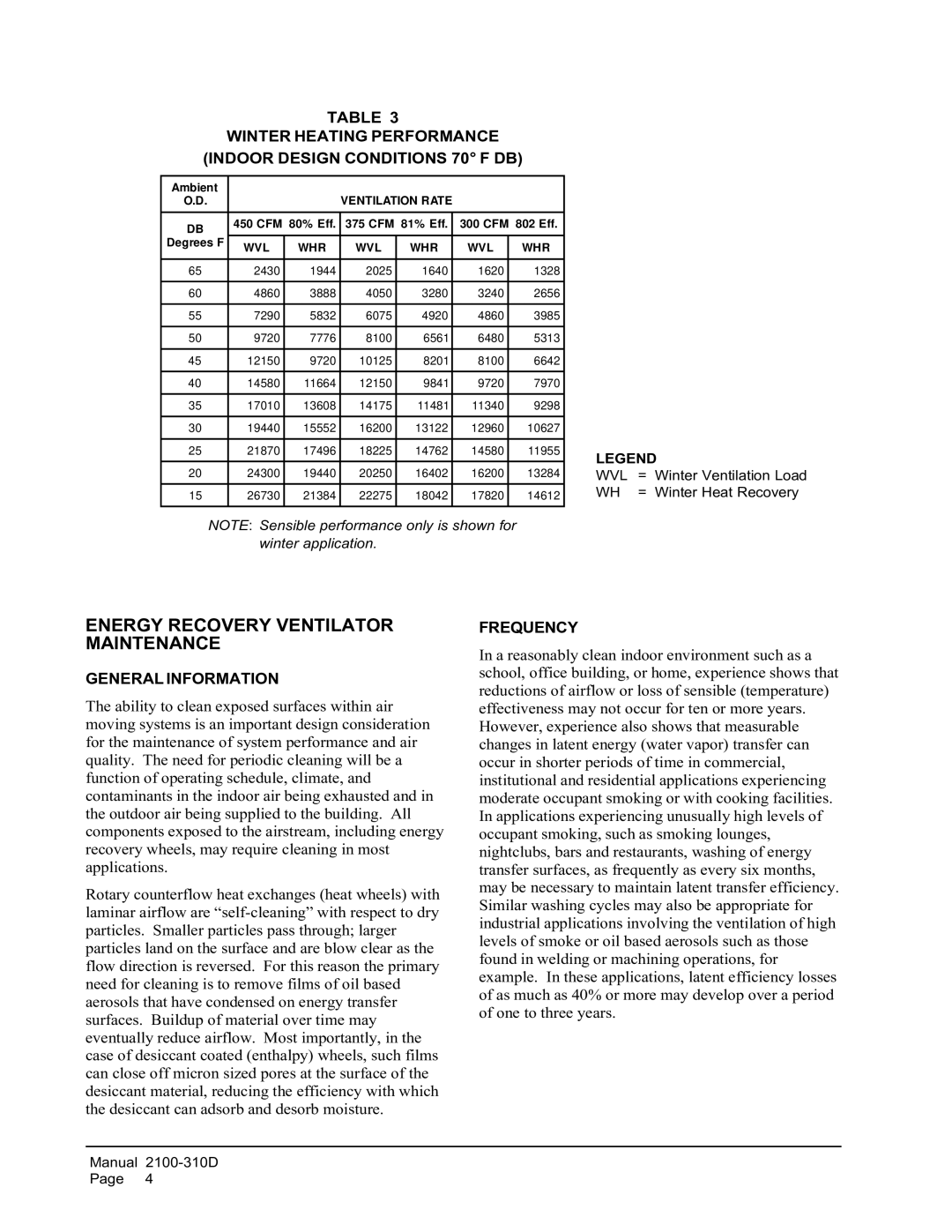

TABLE 3

WINTER HEATING PERFORMANCE

(INDOOR DESIGN CONDITIONS 70° F DB)

Ambient |

|

|

|

|

|

|

O.D. |

|

| VENTILATION RATE |

|

| |

|

|

|

|

|

|

|

DB | 450 CFM 80% Eff. | 375 CFM 81% Eff. | 300 CFM 802 Eff. | |||

|

|

|

|

|

| |

Degrees F | WVL | WHR | WVL | WHR | WVL | WHR |

| ||||||

|

|

|

|

|

|

|

65 | 2430 | 1944 | 2025 | 1640 | 1620 | 1328 |

|

|

|

|

|

|

|

60 | 4860 | 3888 | 4050 | 3280 | 3240 | 2656 |

|

|

|

|

|

|

|

55 | 7290 | 5832 | 6075 | 4920 | 4860 | 3985 |

|

|

|

|

|

|

|

50 | 9720 | 7776 | 8100 | 6561 | 6480 | 5313 |

|

|

|

|

|

|

|

45 | 12150 | 9720 | 10125 | 8201 | 8100 | 6642 |

|

|

|

|

|

|

|

40 | 14580 | 11664 | 12150 | 9841 | 9720 | 7970 |

|

|

|

|

|

|

|

35 | 17010 | 13608 | 14175 | 11481 | 11340 | 9298 |

|

|

|

|

|

|

|

30 | 19440 | 15552 | 16200 | 13122 | 12960 | 10627 |

|

|

|

|

|

|

|

25 | 21870 | 17496 | 18225 | 14762 | 14580 | 11955 |

|

|

|

|

|

|

|

20 | 24300 | 19440 | 20250 | 16402 | 16200 | 13284 |

|

|

|

|

|

|

|

15 | 26730 | 21384 | 22275 | 18042 | 17820 | 14612 |

|

|

|

|

|

|

|

NOTE: Sensible performance only is shown for winter application.

LEGEND

WVL | = | Winter Ventilation Load |

WH | = | Winter Heat Recovery |

ENERGY RECOVERY VENTILATOR MAINTENANCE

GENERAL INFORMATION

The ability to clean exposed surfaces within air moving systems is an important design consideration for the maintenance of system performance and air quality. The need for periodic cleaning will be a function of operating schedule, climate, and contaminants in the indoor air being exhausted and in the outdoor air being supplied to the building. All components exposed to the airstream, including energy recovery wheels, may require cleaning in most applications.

Rotary counterflow heat exchanges (heat wheels) with laminar airflow are

FREQUENCY

In a reasonably clean indoor environment such as a school, office building, or home, experience shows that reductions of airflow or loss of sensible (temperature) effectiveness may not occur for ten or more years. However, experience also shows that measurable changes in latent energy (water vapor) transfer can occur in shorter periods of time in commercial, institutional and residential applications experiencing moderate occupant smoking or with cooking facilities. In applications experiencing unusually high levels of occupant smoking, such as smoking lounges, nightclubs, bars and restaurants, washing of energy transfer surfaces, as frequently as every six months, may be necessary to maintain latent transfer efficiency. Similar washing cycles may also be appropriate for industrial applications involving the ventilation of high levels of smoke or oil based aerosols such as those found in welding or machining operations, for example. In these applications, latent efficiency losses of as much as 40% or more may develop over a period of one to three years.

Manual