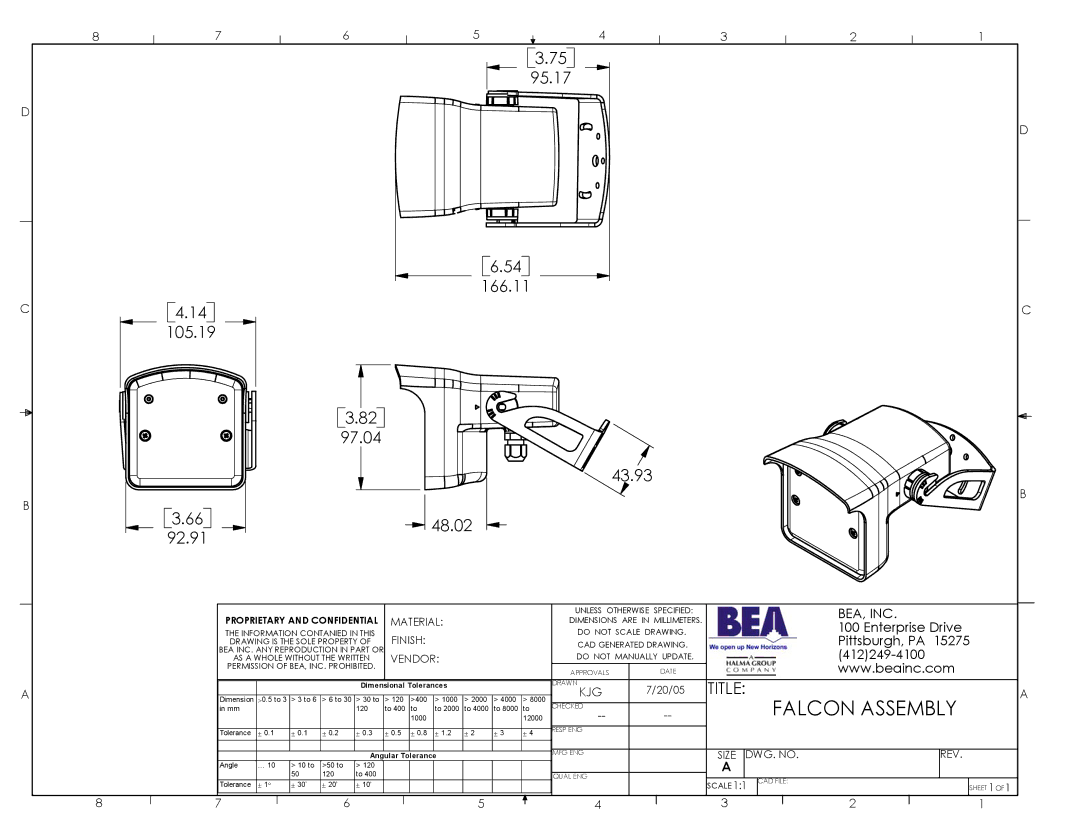

Falcon Assembly specifications

The BEA Falcon Assembly is a cutting-edge technological innovation that has garnered attention in the realm of advanced manufacturing and assembly solutions. This robust and versatile assembly platform is designed to facilitate various industrial applications, notably in sectors such as aerospace, automotive, and electronics. With its state-of-the-art features and technologies, the Falcon Assembly is engineered to optimize productivity while ensuring precision and quality.One of the defining characteristics of the BEA Falcon Assembly is its modular design. This modularity allows for flexibility in configuration, enabling manufacturers to adapt the system according to their unique assembly requirements. The Falcon can seamlessly integrate into existing production lines or function as an independent assembly cell, catering to diverse operational needs.

Key features of the Falcon Assembly include advanced robotics and automation capabilities. Equipped with high-performance robotic arms, the system can execute intricate assembly tasks with unparalleled accuracy. The integration of Artificial Intelligence and machine learning algorithms enhances the system's adaptability, allowing it to learn from past operations and improve over time. This continuous learning capability minimizes errors and reduces downtime, resulting in significant efficiency gains.

Additionally, the BEA Falcon is designed with user-friendly interfaces and interactive control systems. Operators can easily program and monitor assembly processes through intuitive software, enhancing both usability and training efficiency. Real-time data analytics further empower manufacturers to make informed decisions, optimizing production schedules and resource allocation.

The assembly platform also prioritizes safety and ergonomics. With built-in safety features and an emphasis on reducing physical strain for operators, the Falcon Assembly ensures a secure and comfortable working environment. This commitment to safety fosters a culture of well-being within the manufacturing workforce.

Furthermore, the BEA Falcon Assembly is characterized by its sustainability features. Energy-efficient components and eco-friendly materials reduce the environmental impact, aligning with the global push towards sustainable manufacturing practices. This approach not only appeals to environmentally-conscious consumers but also helps companies comply with regulatory standards.

In summary, the BEA Falcon Assembly stands out as a transformative solution for modern manufacturing challenges. Its modular design, advanced automation capabilities, user-friendly interfaces, emphasis on safety, and commitment to sustainability make it a valuable asset for industries looking to enhance their assembly processes while maintaining a competitive edge. With the continued evolution of technology, the Falcon Assembly is positioned to play a pivotal role in shaping the future of manufacturing.