The SmartWave TPMS "Walk Around Learn" feature is a fast and effective method for programming SmartWave TPMS tire sensors into the

Wireless Gateway Receiver. After the system has been installed and the receiver programmed with the number of axles and wheels on the

"WALK AROUND LEARN" FEATURE

vehicle, follow the steps below to program each wheel position.

The SmartWave TPMS "Walk Around Learn" feature is a fast and effective method for programming SmartWave TPMS

• Turn on the tool and press the center button for more than 2 seconds to enter the configuration menu.

tire sensors into the Wireless Gateway Receiver. After the system has been installed and the receiver programmed

with• Prethessnuthembrerighotf baxuttolesnandrepeatedwh ellys ounntilhethevehicle,"Walk fAroundoll w theLesarn"tepsiconbeloisw hitoghliproggrahtemd aneachd presswheelthepositioncenter. button to select the function.

with• Prethessnuthembrerighotf baxuttolesnandrepeatedwh ellys ounntilhethevehicle,"Walk fAroundoll w theLesarn"tepsiconbeloisw hitoghliproggrahtemd aneachd presswheelthepositioncenter. button to select the function.

•Enter the number of wheels on the vehicle by pressing the left button to increase the value and the right button to decrease the value. When the

1.Turndesiredon thevaluetool isanddisplayed,press thepresscenterthebuttoncenterforbuttonmoretothansave2 thesecondsvalueto. access the configuration menu.

2.Pr• essThethtoeolrigwillht nowbuttonbe rreadyepeatedlyto acceptuntil the "tireWalskenArsorundID Leforarthen" icfionrst iswheelhighlightedpositionand. Usingpressthetheguidecenterbelow,buttongo to stheelectfirstthewheelfunctionposition. on the vehicle,

3. Enholterdthethenumbtool aert tofhewtihre'eeslssiondewthalle vinehicthlee locat(leftibuton otonf theinctirearessesenvsoralue,(usruighallyt buinsttaonlledeatcretheasevalves value)stemandwithpressthethepositioncenterindbuicatttonedtobysaverimthelabel)valueand. press the XXX button. An ID transmission will then be provoked from the tire sensor and captured by the tool. When received, the tool will display the

4. The tool is now ready to accept the tire sensor ID for the first wheel position. Use the guide below to determine the programming sequence. To tire sensor's ID number. If an ID number is not displayed, the transmission was not captured and the step must be repeated.

provoke a transmission, position the tool at the tire's sidewall in the location of the tire sensor (usually at valve stem as indicated by a rim label) and press• Repeatthe stepXXX button4 until.tireWhensensorreceivedID numbersby the tool,for eachthe scrwheelnpositionwill displayare thecaptuireredsensor'sby the toolID numberand thenandpressautomaticallythe XXX buttonmove to stheavenextthe datapositionto thein tool.

s•eTurquenncone. thRepeate SmaifrtWnoaIDve nuTPMmSbesystr isedismpblayedy turn. ing on the vehicle / accessory power.

5. Re• Copennectat stepthe4 untooltil tallo tthiree XsenXXsorportIDonnuthmebecablers areharnesscapturedusingandthepresssuppltheiedrightcablebut. ton to save the data to the tool.

6. Tu• Prern ossn the XSXXmartWavbuttone toTPMStransfersystemthebydataturningcapturonedthebyvthehice tleool/ tacco theessWoryirelesspowerG.ateway Receiver.

| | | | 7. | | C | o | nn | ect | t | he | | too | l | to | | the | | diagno | stics p | ort | on t | he | c | ab | le h | arn | e | ss | | usin | g t | he s | upp | lied | | connectio | n ca | ble | . | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | When | | complet | | ed | | successfully, | XXXX. If an | error | occurs | | during the | transfer | and | a | warnin | g tr | iangle | is d | i | spl | a | ye | d | , XXXX | XX | . | | | | | | Walk Around Learn Icon |

| | | | | | | | | | | |

| | | | 8. | | Press | the | | XXX | | button | to | | transfer | | the | tire | sensor | | ID | data | from | | the | tool | to | the | Wireless | | Gateway | | Receiver. | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

When completed successfully, the screen will show a check mark and then return to the configuration menu. If an error occurs during the transfer, a warning triangle will be displayed. Check the cable for damage, ensure it is securely connected and repeat step 8 to transfer the data to the receiver.

"WALK AROUND LEARN" FEATURE: SMARTIRE MAINTENANCE TOOL

SmarTire™ TPMS (Tire Pressure Monitoring System) Bendix "Walk Around Learn" feature is a

fast and effective method for programming SmarTire TPMS tire sensors into the wireless gateway receiver. After the system has been installed and the receiver programmed with the number of axles and wheels on the vehicle, foll ow the s

ow the s teps below to program each wheel position using the

teps below to program each wheel position using the  SmarTire maintenance tool.

SmarTire maintenance tool.

| 1. Turn on the tool and press the center button for more | |

| than 2 seconds to access the configuration menu. | Walk Around Learn Icon |

| 2. Press and release the right button repeatedly until the |

| |

| "Walk Around Learn" icon is highlighted | then press the center button to select it. |

| 3. Enter the number of wheels on the | pressing the left button to increase the value |

| the right button to decrease the value. | the correct value is displayed, press the center |

| button to save it to the tool. | | |

4.The tool is now ready to accept the tire sensor ID number for the first wheel position. Use the guide on the reverse side of this card to determine the programming sequence. To provoke a transmission, position the tool at the tire's sidewall in the location of the tire sensor (usually at

valve stem as indicated by a rim label) and press the center button. When received | the tool, |

the screen will display the tire sensor's ID number and automatically move to the | position in |

sequence. If no ID number is displayed, repeat the process. If a wheel position out of sequence is |

provoked, press | left button to revert back to the previous position and repeat the |

at the correct wheel | . | |

4 until all tire sensor ID numbers are captured and press the right button to save the

.

™ TPMS by Bendix CVS system by turning on the vehicle / accessory power.

7. | | | | the t | o | ol | | | | diag | nosti | cs port on th | e | cab | le h | a | rne | s | s us | i | ng | the | | | | co | nne | c | tion | cab | le. |

8. | | | the | | | | | | | | transfer | | | tire | sensor | | | | | | | from | | | | | | | | | | | | | gateway | | | |

| | left | | | to | | the | | ID | | data | | the | | tool | | to | | | | | | | | | |

| | | . | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

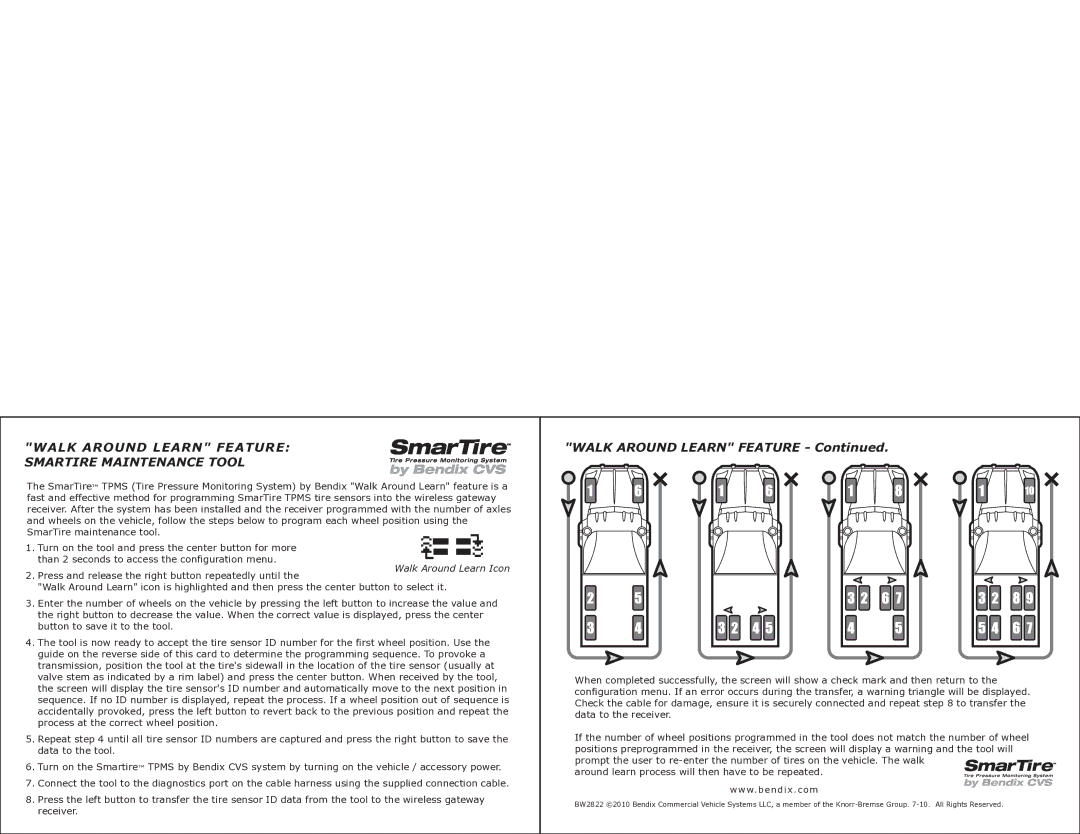

"WALK AROUND LEARN" FEATURE - Continued.

successfully, the screen will show a check mark and then return to the |

menu. If an error occurs during the transfer, a warning triangle will be displayed. |

cable for damage, ensure it is securely connected and repeat step 8 to transfer the |

data to the receiver. | |

If the number of wheel positions programmed in the tool does not match | number of wheel |

positions preprogrammed in the receiver, the screen will display a warning and the tool will |

prompt the user to re-enter the number of tires on the vehicle. The walk | |

around learn process will then have to be repeated. | |

www.bendix.com

BW2822 ©2010 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group. 7-10. All Rights Reserved.