extended yoke adapter is also available as a separate service item. The extended adapter is 1/2 inch longer than the standard, and is primarily intended for use when the existing brake actuator push rod is too short.

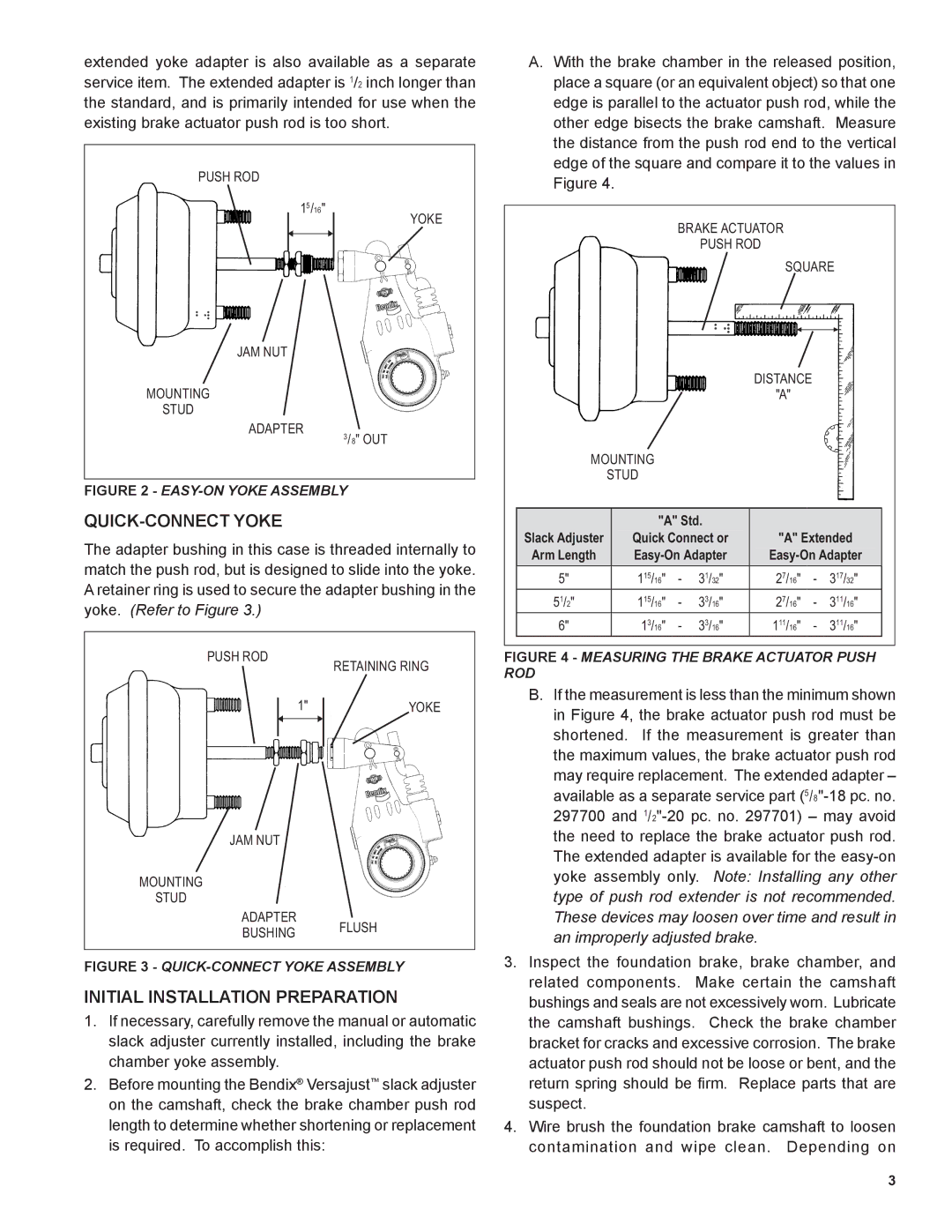

A. With the brake chamber in the released position, |

place a square (or an equivalent object) so that one |

edge is parallel to the actuator push rod, while the |

other edge bisects the brake camshaft. Measure |

the distance from the push rod end to the vertical |

edge of the square and compare it to the values in |

PUSH ROD

15/16"

JAM NUT

MOUNTING

STUD

ADAPTER

YOKE

3/8" OUT

Figure 4. |

BRAKE ACTUATOR |

PUSH ROD |

SQUARE |

DISTANCE |

"A" |

MOUNTING |

STUD |

FIGURE 2 - EASY-ON YOKE ASSEMBLY

QUICK‑CONNECT YOKE

The adapter bushing in this case is threaded internally to match the push rod, but is designed to slide into the yoke. A retainer ring is used to secure the adapter bushing in the yoke. (Refer to Figure 3.)

|

| "A" Std. |

|

|

| ||

Slack Adjuster |

| Quick Connect or |

|

| "A" Extended | ||

Arm Length |

|

|

|

| |||

5" | 115/16" - | 31/32" |

| 27/16" - 317/32" |

| ||

51/2" | 115/16" - | 33/16" |

| 27/16" - 311/16" |

| ||

6" | 13/16" - | 33/16" |

| 111/16" - 311/16" |

| ||

PUSH ROD

1"

JAM NUT

MOUNTING

STUD

ADAPTER

BUSHING

RETAINING RING

YOKE

FLUSH

FIGURE 4 - MEASURING THE BRAKE ACTUATOR PUSH ROD

B. If the measurement is less than the minimum shown |

in Figure 4, the brake actuator push rod must be |

shortened. If the measurement is greater than |

the maximum values, the brake actuator push rod |

may require replacement. The extended adapter – |

available as a separate service part |

297700 and 1/2"‑20 pc. no. 297701) – may avoid |

the need to replace the brake actuator push rod. |

The extended adapter is available for the easy‑on |

yoke assembly only. Note: Installing any other |

type of push rod extender is not recommended. |

These devices may loosen over time and result in |

an improperly adjusted brake. |

FIGURE 3 - QUICK-CONNECT YOKE ASSEMBLY

INITIAL INSTALLATION PREPARATION

1.If necessary, carefully remove the manual or automatic slack adjuster currently installed, including the brake chamber yoke assembly.

2.Before mounting the Bendix® Versajust™ slack adjuster on the camshaft, check the brake chamber push rod length to determine whether shortening or replacement is required. To accomplish this:

3. Inspect the foundation brake, brake chamber, and |

related components. Make certain the camshaft |

bushings and seals are not excessively worn. Lubricate |

the camshaft bushings. Check the brake chamber |

bracket for cracks and excessive corrosion. The brake |

actuator push rod should not be loose or bent, and the |

return spring should be firm. Replace parts that are |

suspect. |

4. Wire brush the foundation brake camshaft to loosen |

contamination and wipe clean. Depending on |

3