GMB specifications

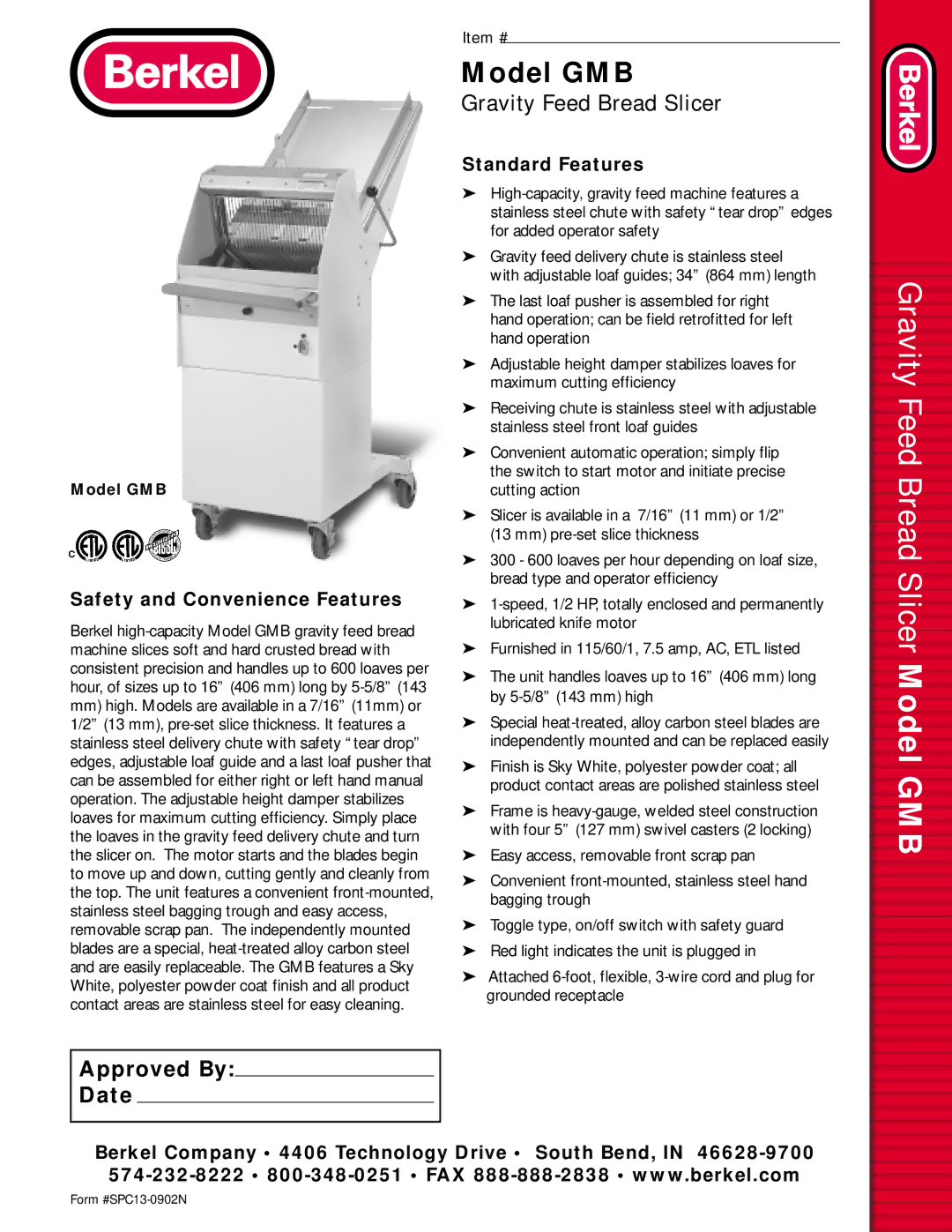

Berkel GMB is a prominent name in the realms of food processing and packaging technology, renowned for its innovative solutions that cater to a wide variety of industries. Established with a vision to revolutionize food production, the company has developed a strong reputation for its high-quality, efficient, and reliable machinery.One of the main features that sets Berkel GMB apart is its extensive range of products designed for food slicing, dicing, grinding, and packaging. This versatility allows the company to serve diverse sectors, including meat processing, dairy, bakery, and general food production. Each machine is engineered with precision to meet the specific needs of the clients, enhancing productivity and ensuring the highest standards of food safety.

Berkel GMB places a strong emphasis on technology, investing continually in research and development to stay at the forefront of industry demands. The company employs advanced automation technologies to improve operational efficiency. Smart, user-friendly interfaces and integrated software solutions ensure that operators can manage the machinery with ease, leading to reduced training times and lower chances of error.

Another noteworthy characteristic of Berkel products is their dedication to sustainability. The company is committed to minimizing environmental impact by utilizing energy-efficient technologies and promoting practices that reduce waste. Moreover, many of their machines are designed with maintenance in mind, ensuring longevity and reliability, which further contributes to sustainability efforts.

Safety is another cornerstone of Berkel GMB’s offerings, with features that protect operators and maintain the integrity of products. Safety guards, emergency stop functions, and adherence to international safety standards are fundamental components across their equipment lineup.

Furthermore, Berkel GMB recognizes the importance of customization. Whether it is specific slicing thickness or particular packaging requirements, the company works closely with clients to tailor solutions that fit their unique operational contexts. This level of customer-centric service enhances client satisfaction and encourages long-term partnerships.

In summary, Berkel GMB stands out in the food processing industry through its wide array of innovative machinery, commitment to technological advancement, focus on sustainability, strong safety standards, and dedication to customization. All these factors combine to make Berkel GMB a leader in the food processing technology sector, helping businesses improve their production capabilities while adhering to modern requirements and standards.