FORCE BLOWER

MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation | Every | Daily or Every | Every 25 | Every 50 | Every |

| Use | 5 Hours | Hours | Hours | |

|

|

|

|

| Hours |

|

|

|

|

|

|

Inspect for worn or damaged parts. | z |

|

|

|

|

|

|

|

|

|

|

Check for excessive vibration |

| z |

|

|

|

|

|

|

|

|

|

Check belt/chain tightness | z |

|

|

|

|

|

|

|

|

|

|

Oil drive chain |

| z |

|

|

|

|

|

|

|

|

|

Inspect Impeller for cracks or damage |

|

|

|

| z |

|

|

|

|

|

|

Inspect for loose parts. |

| z |

|

|

|

|

|

|

|

|

|

IMPELLER REMOVAL

1.Wait for engine to cool and disconnect spark plug.

2.Remove housing front cover, by removing (11) bolts and nuts, items #13 & #14, around outside of front cover.

3.Remove impeller bolt (item #35), lock washer (item #71) and washer (item #34).

4.DO NOT pry on impeller. Pull on center hub area only of impeller. Using a penetrating oil can help loosen a stuck impeller.

5.Reinstall new impeller in reverse order of removal.

6.Tighten impeller bolt. Torque impeller bolt (see parts list on page 15 for proper impeller bolt torque specifications).

TIRE AIR PRESSURE

Check at regular intervals and maintain.

Front Tires - 24 Psi (165 kPa).

Rear Tires - 20 Psi (137 kPa).

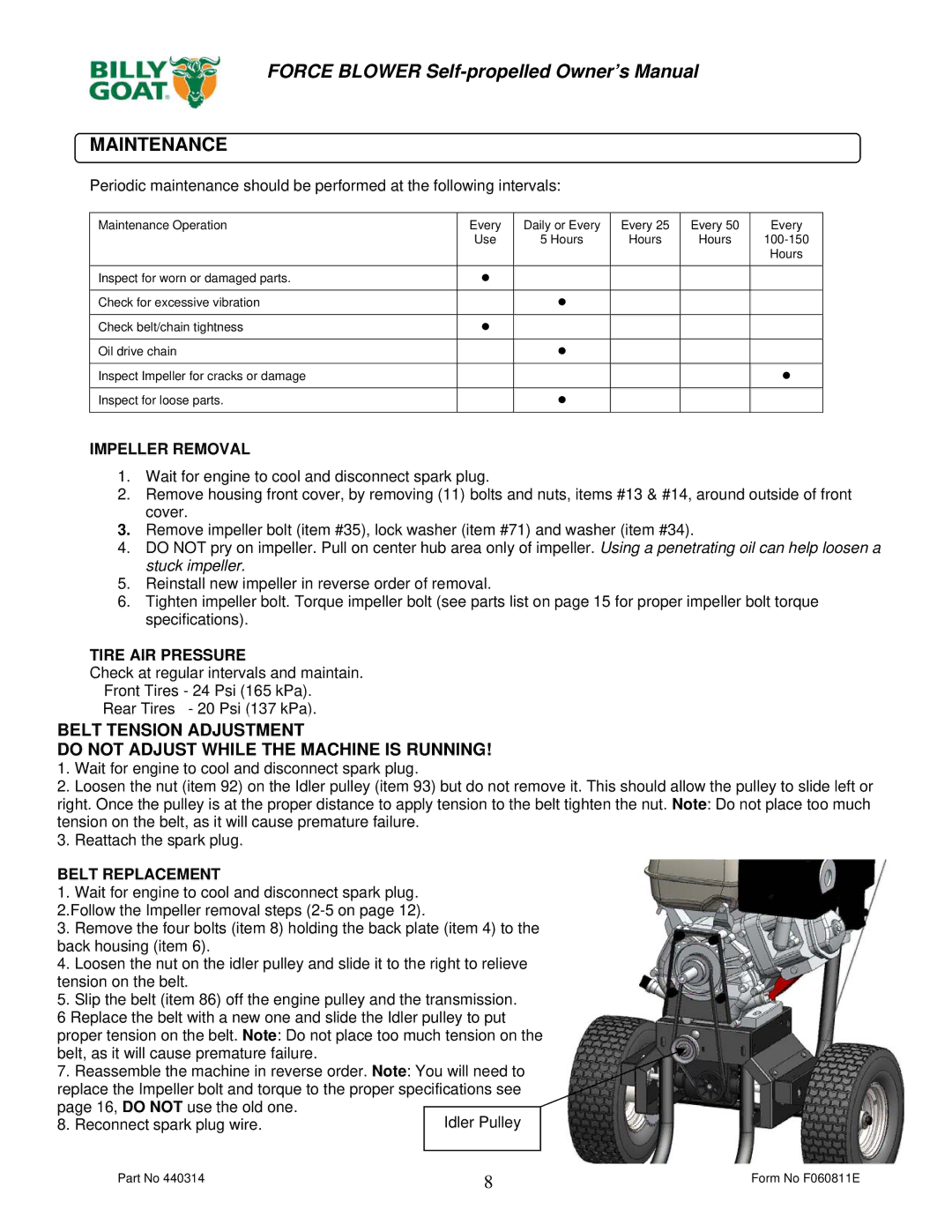

BELT TENSION ADJUSTMENT

DO NOT ADJUST WHILE THE MACHINE IS RUNNING!

1.Wait for engine to cool and disconnect spark plug.

2.Loosen the nut (item 92) on the Idler pulley (item 93) but do not remove it. This should allow the pulley to slide left or right. Once the pulley is at the proper distance to apply tension to the belt tighten the nut. Note: Do not place too much tension on the belt, as it will cause premature failure.

3.Reattach the spark plug.

BELT REPLACEMENT

1.Wait for engine to cool and disconnect spark plug. 2.Follow the Impeller removal steps

3.Remove the four bolts (item 8) holding the back plate (item 4) to the back housing (item 6).

4.Loosen the nut on the idler pulley and slide it to the right to relieve tension on the belt.

5.Slip the belt (item 86) off the engine pulley and the transmission.

6Replace the belt with a new one and slide the Idler pulley to put proper tension on the belt. Note: Do not place too much tension on the belt, as it will cause premature failure.

7.Reassemble the machine in reverse order. Note: You will need to replace the Impeller bolt and torque to the proper specifications see

page 16, DO NOT use the old one. 8. Reconnect spark plug wire.

Part No 440314 | 8 | Form No F060811E |