6 ” B E N C H G R I N D E R

INSTRUCTION

MANUAL

CATALOG NUMBER

BT3500

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO (544-6986)

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR BLACK & DECKER PURCHASE,

CALL 1-800-54-HOW-TO (1-800-544-6986).

IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO THE SUCCESS OF BLACK & DECKER’S QUALITY

IMPROVEMENT PROGRAM.

KEY INFORMATION YOU SHOULD KNOW:

•Always wear eye protection.

•Make sure tool rests, spark guards, and eye shields are firmly secured before tool is engaged.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓ N, CENTROS DE SERVICIO Y

PÓ LIZA DE GARANTÍA. ADVERTENCIA: LÉ ASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

CAT. NOS. BT3500 FORM NO.

![]() WARNING: For your own safety read instruction manual before operating tool.

WARNING: For your own safety read instruction manual before operating tool.

Grounding Instructions

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

Improper connection of the

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

Use only

Repair or replace damaged or worn cords immediately.

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Figure A. The tool has a grounding plug that looks like the plug illustrated in Figure A. A temporary adapter, which looks the adapter illustrated in Figures B and C, may be used to connect this plug to a

| GROUNDED |

|

|

A | OUTLET | B | C |

| BOX |

| GROUNDING |

|

|

| |

|

|

| MEANS |

GROUNDING PIN |

| ||

|

| ||

![]() WARNING: Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious personal injury.

WARNING: Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious personal injury.

Important Safety Instructions

•KEEP GUARDS IN PLACE and in working order.

•REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

•KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

•DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose them to rain. Keep work area well lighted.

•KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

•MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

•DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

•USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

•USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using and extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

•OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension cords intended for use outdoors and so marked.

|

|

| Minimum Gage for Cord Sets |

| ||

Volts |

|

| Total Length of Cord in Feet | |||

120V |

| |||||

240V |

| |||||

Ampere Rating |

|

|

| |||

More |

| Not more | American Wire Gage |

| ||

Than |

| Than |

|

|

|

|

0 | - | 6 | 18 | 16 | 16 | 14 |

6 | - | 10 | 18 | 16 | 14 | 12 |

10 | - | 12 | 16 | 16 | 14 | 12 |

12 | - | 16 | 14 | 12 | Not Recommended | |

•WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

•ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

•DON’T OVERREACH. Keep proper footing and balance at all times.

•MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest per- formance. Follow instructions for changing accessories.

•DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits, cutters, and the like.

•REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position before plugging in.

•USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended accessories. The use of improper accessories may cause risk of injury to persons.

•NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally contacted.

•CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended

•NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool until it comes to a complete stop.

ADDITIONAL SAFETY RULES FOR BENCH GRINDERS

•Always use proper guard with grinding wheel. A guard protects operator from broken wheel fragments.

•Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories running over the rated speed can fly apart and cause injury.

•Before using, inspect recommended accessory for cracks or flaws. If such a crack or flaw is evident, discard the accessory. DO NOT USE A GRINDING WHEEL THAT IS CRACKED OR FLAWED IN ANY WAY.

•When starting the tool, let it run for one minute. Never start the tool with a person in line with the wheel. This includes the operator.

•Do not grind on the sides of grinding wheels unless they are specifically designed for that purpose.

•Do not overtighten wheel clamp nut. This may crack the grinding wheel.

•Clean the cavity around the grinding wheel periodically.

•Secure grinder to work bench or stand with clamps or mounting hardware. Secure work bench or stand to floor.

•Make sure your fingers do not contact the terminals of the power cord when installing or removing the plug to or from the line power source.

•DO NOT OPERATE THIS TOOL NEAR FLAMMABLE LIQUIDS, GASES OR DUST. Sparks or hot chips from grinding may ignite combustible materials.

![]() WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

The label on your tool may include the following symbols.

V | volts | A | amperes | |||||

Hz | hertz | W | watts | |||||

min | minutes | no | alternating current | |||||

|

| direct current | no load speed | |||||

|

| |||||||

| ..........................Class II Construction |

|

|

| ........................ | earthing terminal | ||

|

|

|

|

|

| |||

|

|

| ||||||

| ........................ | safety alert symbol | .../min | revolutions or | ||||

|

|

|

|

|

|

|

| reciprocations |

|

|

|

|

|

|

|

| per minute |

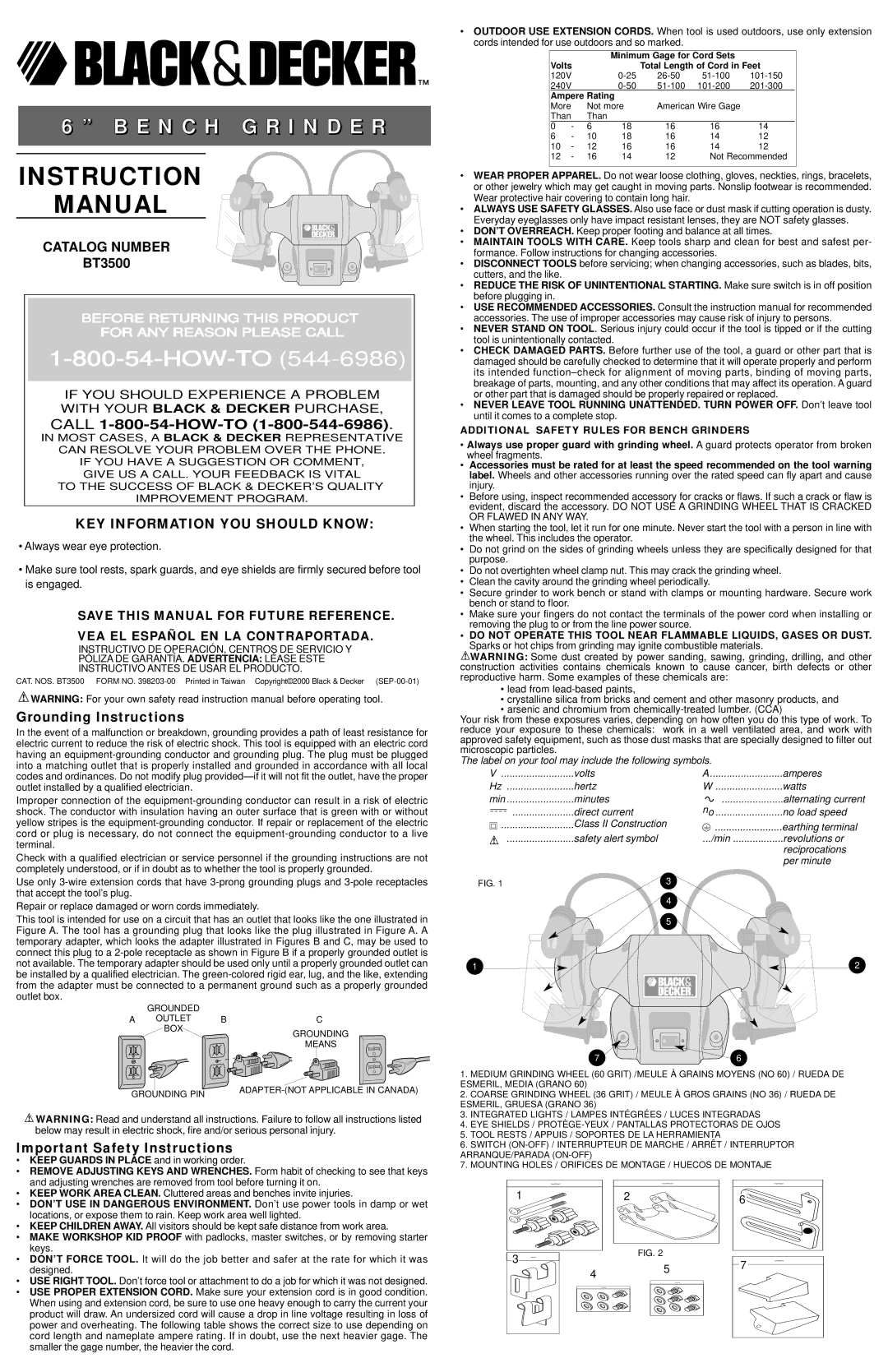

FIG. 1 |

| 3 |

|

|

|

|

| |

4

5

1 | 2 |

7 | 6 |

1.MEDIUM GRINDING WHEEL (60 GRIT) /MEULE À GRAINS MOYENS (NO 60) / RUEDA DE ESMERIL, MEDIA (GRANO 60)

2.COARSE GRINDING WHEEL (36 GRIT) / MEULE À GROS GRAINS (NO 36) / RUEDA DE ESMERIL, GRUESA (GRANO 36)

3.INTEGRATED LIGHTS / LAMPES INTÉGRÉES / LUCES INTEGRADAS

4.EYE SHIELDS /

5.TOOL RESTS / APPUIS / SOPORTES DE LA HERRAMIENTA

6.SWITCH

7.MOUNTING HOLES / ORIFICES DE MONTAGE / HUECOS DE MONTAJE

1 | 2 | 6 |

|

|

3 |

| FIG. 2 |

|

| 5 | 7 | |

| 4 | ||

|

| ||

|

|

|