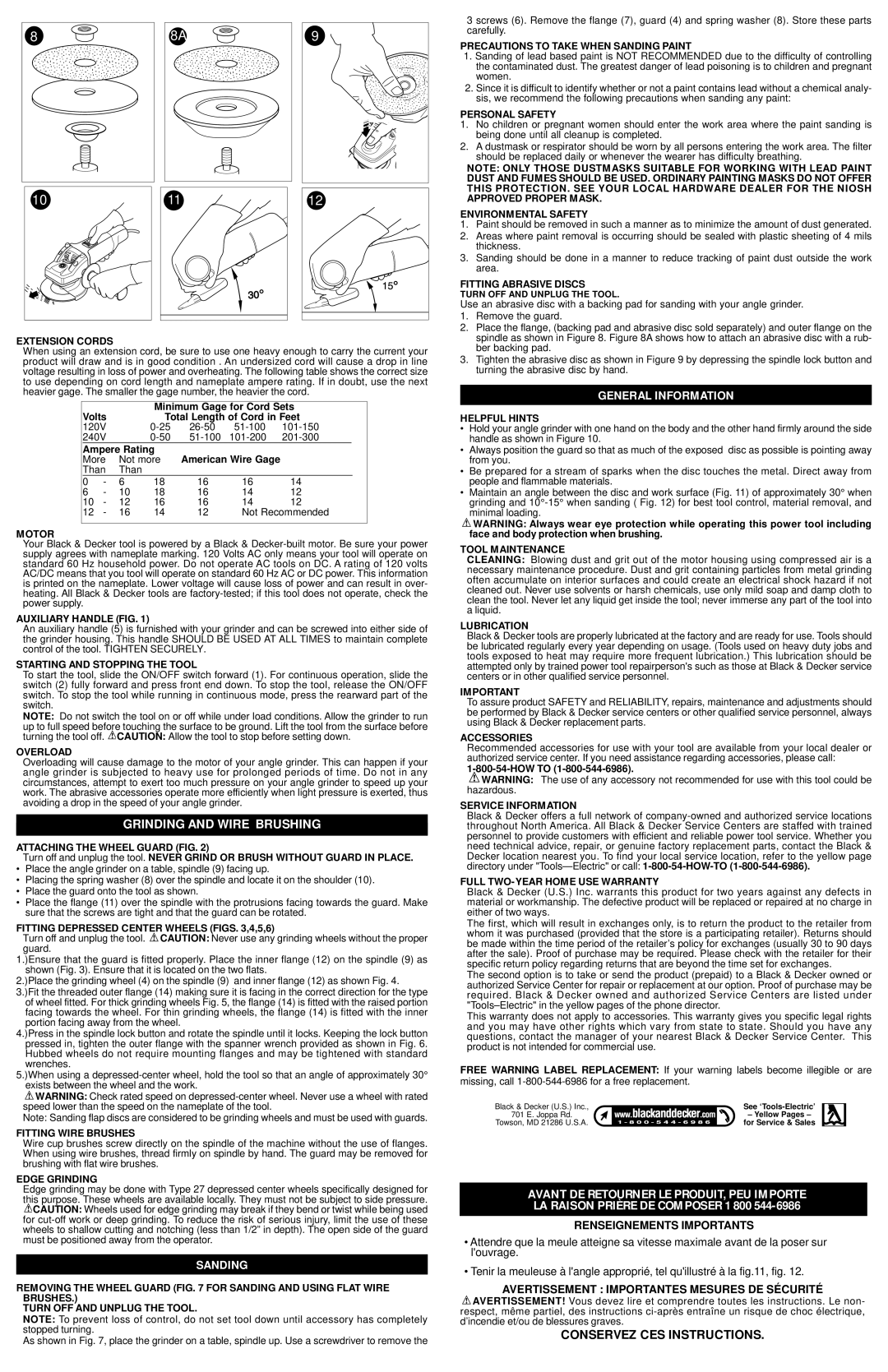

8 | 8A | 9 |

10 | 11 | 12 |

EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw and is in good condition . An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

|

|

| Minimum Gage for Cord Sets | |||

Volts |

| Total Length of Cord in Feet | ||||

120V |

| |||||

240V |

| |||||

Ampere Rating | American Wire Gage |

| ||||

More | Not more |

| ||||

Than | Than |

|

|

|

| |

0 | - | 6 | 18 | 16 | 16 | 14 |

6 | - | 10 | 18 | 16 | 14 | 12 |

10 | - | 12 | 16 | 16 | 14 | 12 |

12 | - | 16 | 14 | 12 | Not Recommended | |

MOTOR

Your Black & Decker tool is powered by a Black &

AUXILIARY HANDLE (FIG. 1)

An auxiliary handle (5) is furnished with your grinder and can be screwed into either side of the grinder housing. This handle SHOULD BE USED AT ALL TIMES to maintain complete control of the tool. TIGHTEN SECURELY.

STARTING AND STOPPING THE TOOL

To start the tool, slide the ON/OFF switch forward (1). For continuous operation, slide the switch (2) fully forward and press front end down. To stop the tool, release the ON/OFF switch. To stop the tool while running in continuous mode, press the rearward part of the switch.

NOTE: Do not switch the tool on or off while under load conditions. Allow the grinder to run up to full speed before touching the surface to be ground. Lift the tool from the surface before turning the tool off. ![]() CAUTION: Allow the tool to stop before setting down.

CAUTION: Allow the tool to stop before setting down.

OVERLOAD

Overloading will cause damage to the motor of your angle grinder. This can happen if your angle grinder is subjected to heavy use for prolonged periods of time. Do not in any circumstances, attempt to exert too much pressure on your angle grinder to speed up your work. The abrasive accessories operate more efficiently when light pressure is exerted, thus avoiding a drop in the speed of your angle grinder.

GRINDING AND WIRE BRUSHING

ATTACHING THE WHEEL GUARD (FIG. 2)

Turn off and unplug the tool. NEVER GRIND OR BRUSH WITHOUT GUARD IN PLACE.

•Place the angle grinder on a table, spindle (9) facing up.

•Placing the spring washer (8) over the spindle and locate it on the shoulder (10).

•Place the guard onto the tool as shown.

•Place the flange (11) over the spindle with the protrusions facing towards the guard. Make sure that the screws are tight and that the guard can be rotated.

FITTING DEPRESSED CENTER WHEELS (FIGS. 3,4,5,6)

Turn off and unplug the tool. ![]() CAUTION: Never use any grinding wheels without the proper guard.

CAUTION: Never use any grinding wheels without the proper guard.

1.)Ensure that the guard is fitted properly. Place the inner flange (12) on the spindle (9) as shown (Fig. 3). Ensure that it is located on the two flats.

2.)Place the grinding wheel (4) on the spindle (9) and inner flange (12) as shown Fig. 4.

3.)Fit the threaded outer flange (14) making sure it is facing in the correct direction for the type of wheel fitted. For thick grinding wheels Fig. 5, the flange (14) is fitted with the raised portion facing towards the wheel. For thin grinding wheels, the flange (14) is fitted with the inner portion facing away from the wheel.

4.)Press in the spindle lock button and rotate the spindle until it locks. Keeping the lock button pressed in, tighten the outer flange with the spanner wrench provided as shown in Fig. 6. Hubbed wheels do not require mounting flanges and may be tightened with standard wrenches.

5.)When using a

![]() WARNING: Check rated speed on

WARNING: Check rated speed on

Note: Sanding flap discs are considered to be grinding wheels and must be used with guards.

FITTING WIRE BRUSHES

Wire cup brushes screw directly on the spindle of the machine without the use of flanges. When using wire brushes, thread firmly on spindle by hand. The guard may be removed for brushing with flat wire brushes.

EDGE GRINDING

Edge grinding may be done with Type 27 depressed center wheels specifically designed for this purpose. These wheels are available locally. They must not be subject to side pressure. ![]() CAUTION: Wheels used for edge grinding may break if they bend or twist while being used for

CAUTION: Wheels used for edge grinding may break if they bend or twist while being used for

SANDING

REMOVING THE WHEEL GUARD (FIG. 7 FOR SANDING AND USING FLAT WIRE BRUSHES.)

TURN OFF AND UNPLUG THE TOOL.

NOTE: To prevent loss of control, do not set tool down until accessory has completely stopped turning.

As shown in Fig. 7, place the grinder on a table, spindle up. Use a screwdriver to remove the

3 screws (6). Remove the flange (7), guard (4) and spring washer (8). Store these parts carefully.

PRECAUTIONS TO TAKE WHEN SANDING PAINT

1.Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the contaminated dust. The greatest danger of lead poisoning is to children and pregnant women.

2.Since it is difficult to identify whether or not a paint contains lead without a chemical analy- sis, we recommend the following precautions when sanding any paint:

PERSONAL SAFETY

1.No children or pregnant women should enter the work area where the paint sanding is being done until all cleanup is completed.

2.A dustmask or respirator should be worn by all persons entering the work area. The filter should be replaced daily or whenever the wearer has difficulty breathing.

NOTE: ONLY THOSE DUSTMASKS SUITABLE FOR WORKING WITH LEAD PAINT DUST AND FUMES SHOULD BE USED. ORDINARY PAINTING MASKS DO NOT OFFER THIS PROTECTION. SEE YOUR LOCAL HARDWARE DEALER FOR THE NIOSH APPROVED PROPER MASK.

ENVIRONMENTAL SAFETY

1.Paint should be removed in such a manner as to minimize the amount of dust generated.

2.Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils thickness.

3.Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

FITTING ABRASIVE DISCS

TURN OFF AND UNPLUG THE TOOL.

Use an abrasive disc with a backing pad for sanding with your angle grinder.

1.Remove the guard.

2.Place the flange, (backing pad and abrasive disc sold separately) and outer flange on the spindle as shown in Figure 8. Figure 8A shows how to attach an abrasive disc with a rub- ber backing pad.

3.Tighten the abrasive disc as shown in Figure 9 by depressing the spindle lock button and turning the abrasive disc by hand.

GENERAL INFORMATION

HELPFUL HINTS

•Hold your angle grinder with one hand on the body and the other hand firmly around the side handle as shown in Figure 10.

•Always position the guard so that as much of the exposed disc as possible is pointing away from you.

•Be prepared for a stream of sparks when the disc touches the metal. Direct away from people and flammable materials.

•Maintain an angle between the disc and work surface (Fig. 11) of approximately 30° when grinding and

![]() WARNING: Always wear eye protection while operating this power tool including face and body protection when brushing.

WARNING: Always wear eye protection while operating this power tool including face and body protection when brushing.

TOOL MAINTENANCE

CLEANING: Blowing dust and grit out of the motor housing using compressed air is a necessary maintenance procedure. Dust and grit containing particles from metal grinding often accumulate on interior surfaces and could create an electrical shock hazard if not cleaned out. Never use solvents or harsh chemicals, use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

LUBRICATION

Black & Decker tools are properly lubricated at the factory and are ready for use. Tools should be lubricated regularly every year depending on usage. (Tools used on heavy duty jobs and tools exposed to heat may require more frequent lubrication.) This lubrication should be attempted only by trained power tool repairperson's such as those at Black & Decker service centers or in other qualified service personnel.

IMPORTANT

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments should be performed by Black & Decker service centers or other qualified service personnel, always using Black & Decker replacement parts.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or authorized service center. If you need assistance regarding accessories, please call:

![]() WARNING: The use of any accessory not recommended for use with this tool could be hazardous.

WARNING: The use of any accessory not recommended for use with this tool could be hazardous.

SERVICE INFORMATION

Black & Decker offers a full network of

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the store is a participating retailer). Returns should be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the sale). Proof of purchase may be required. Please check with the retailer for their specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for repair or replacement at our option. Proof of purchase may be required. Black & Decker owned and authorized Service Centers are listed under

This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other rights which vary from state to state. Should you have any questions, contact the manager of your nearest Black & Decker Service Center. This product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call

Black & Decker (U.S.) Inc., |

| See | |

| |||

701 | E. Joppa Rd. |

| – Yellow Pages – |

Towson, | MD 21286 U.S.A. |

| for Service & Sales |

AVANT DE RETOURNER LE PRODUIT, PEU IMPORTE

LA RAISON PRIÈRE DE COMPOSER 1 800

RENSEIGNEMENTS IMPORTANTS

•Attendre que la meule atteigne sa vitesse maximale avant de la poser sur l'ouvrage.

•Tenir la meuleuse à l'angle approprié, tel qu'illustré à la fig.11, fig. 12.

AVERTISSEMENT : IMPORTANTES MESURES DE SÉ CURITÉ

![]() AVERTISSEMENT! Vous devez lire et comprendre toutes les instructions. Le non- respect, même partiel, des instructions

AVERTISSEMENT! Vous devez lire et comprendre toutes les instructions. Le non- respect, même partiel, des instructions