AD600 ALKALINE BATTERY DRILL

INSTRUCTION MANUAL

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO (544-6986)

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR BLACK & DECKER PURCHASE,

CALL 1-800-54-HOW-TO (1-800-544-6986).

IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO THE SUCCESS OF BLACK & DECKER'S QUALITY

IMPROVEMENT PROGRAM.

KEY INFORMATION YOU SHOULD

KNOW:

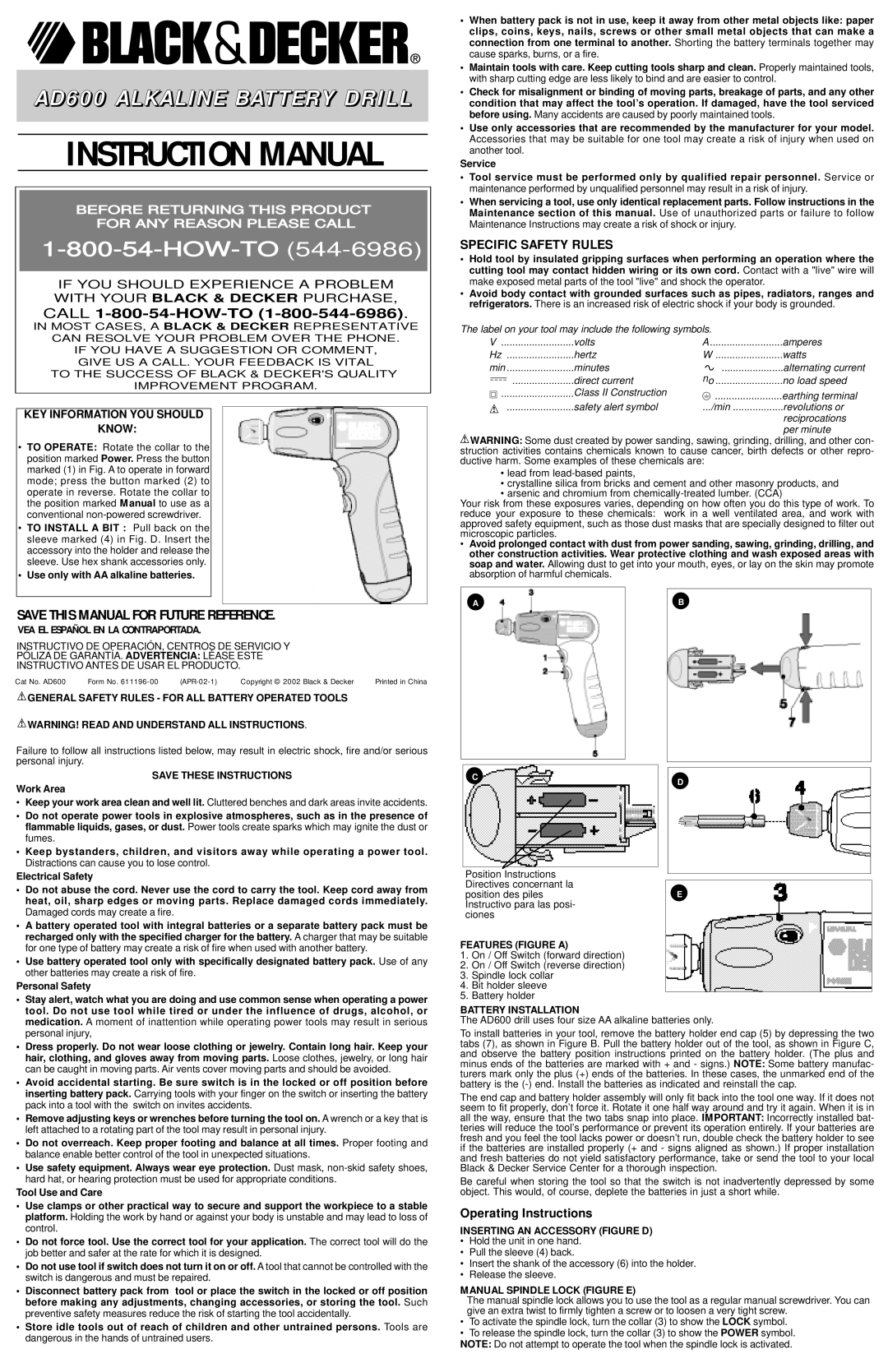

•TO OPERATE: Rotate the collar to the position marked Power. Press the button marked (1) in Fig. A to operate in forward mode; press the button marked (2) to operate in reverse. Rotate the collar to the position marked Manual to use as a conventional

•TO INSTALL A BIT : Pull back on the sleeve marked (4) in Fig. D. Insert the accessory into the holder and release the sleeve. Use hex shank accessories only.

•Use only with AA alkaline batteries.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓ N, CENTROS DE SERVICIO Y

PÓ LIZA DE GARANTÍA. ADVERTENCIA: LÉ ASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Cat No. AD600 | Form No. | Copyright © 2002 Black & Decker | Printed in China |

GENERAL SAFETY RULES - FOR ALL BATTERY OPERATED TOOLS

GENERAL SAFETY RULES - FOR ALL BATTERY OPERATED TOOLS

![]() WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS.

WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

•Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

•Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

•Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause you to lose control.

Electrical Safety

•Do not abuse the cord. Never use the cord to carry the tool. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords may create a fire.

•A battery operated tool with integral batteries or a separate battery pack must be recharged only with the specified charger for the battery. A charger that may be suitable for one type of battery may create a risk of fire when used with another battery.

•Use battery operated tool only with specifically designated battery pack. Use of any other batteries may create a risk of fire.

Personal Safety

•Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury,

•Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts. Air vents cover moving parts and should be avoided.

•Avoid accidental starting. Be sure switch is in the locked or off position before inserting battery pack. Carrying tools with your finger on the switch or inserting the battery pack into a tool with the switch on invites accidents.

•Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left attached to a rotating part of the tool may result in personal injury.

•Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enable better control of the tool in unexpected situations.

•Use safety equipment. Always wear eye protection. Dust mask,

Tool Use and Care

•Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

•Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

•Do not use tool if switch does not turn it on or off. A tool that cannot be controlled with the switch is dangerous and must be repaired.

•Disconnect battery pack from tool or place the switch in the locked or off position before making any adjustments, changing accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

•Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

•When battery pack is not in use, keep it away from other metal objects like: paper clips, coins, keys, nails, screws or other small metal objects that can make a connection from one terminal to another. Shorting the battery terminals together may cause sparks, burns, or a fire.

•Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edge are less likely to bind and are easier to control.

•Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tool’s operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools.

•Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool may create a risk of injury when used on another tool.

Service

•Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel may result in a risk of injury.

•When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a risk of shock or injury.

SPECIFIC SAFETY RULES

•Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will make exposed metal parts of the tool "live" and shock the operator.

•Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded.

The label on your tool may include the following symbols.

V | volts | A | amperes | |||

Hz | hertz | W | watts | |||

min | minutes | no | alternating current | |||

|

| direct current | no load speed | |||

|

| |||||

| .......................... | Class II Construction |

|

| ........................ | earthing terminal |

|

|

|

|

| ||

|

|

|

|

| ||

| ........................ | safety alert symbol | .../min | revolutions or | ||

|

|

|

|

|

| reciprocations |

|

|

|

|

|

| per minute |

![]() WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con- struction activities contains chemicals known to cause cancer, birth defects or other repro- ductive harm. Some examples of these chemicals are:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con- struction activities contains chemicals known to cause cancer, birth defects or other repro- ductive harm. Some examples of these chemicals are:

•lead from

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

•Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

|

|

|

A |

| B |

|

|

|

|

|

|

C | D |

|

Position Instructions Directives concernant la

position des pilesE Instructivo para las posi-

ciones

FEATURES (FIGURE A)

1.On / Off Switch (forward direction)

2.On / Off Switch (reverse direction)

3.Spindle lock collar

4.Bit holder sleeve

5.Battery holder

BATTERY INSTALLATION

The AD600 drill uses four size AA alkaline batteries only.

To install batteries in your tool, remove the battery holder end cap (5) by depressing the two tabs (7), as shown in Figure B. Pull the battery holder out of the tool, as shown in Figure C, and observe the battery position instructions printed on the battery holder. (The plus and minus ends of the batteries are marked with + and - signs.) NOTE: Some battery manufac- turers mark only the plus (+) ends of the batteries. In these cases, the unmarked end of the battery is the

The end cap and battery holder assembly will only fit back into the tool one way. If it does not seem to fit properly, don’t force it. Rotate it one half way around and try it again. When it is in all the way, ensure that the two tabs snap into place. IMPORTANT: Incorrectly installed bat- teries will reduce the tool’s performance or prevent its operation entirely. If your batteries are fresh and you feel the tool lacks power or doesn’t run, double check the battery holder to see if the batteries are installed properly (+ and - signs aligned as shown.) If proper installation and fresh batteries do not yield satisfactory performance, take or send the tool to your local Black & Decker Service Center for a thorough inspection.

Be careful when storing the tool so that the switch is not inadvertently depressed by some object. This would, of course, deplete the batteries in just a short while.

Operating Instructions

INSERTING AN ACCESSORY (FIGURE D)

•Hold the unit in one hand.

•Pull the sleeve (4) back.

•Insert the shank of the accessory (6) into the holder.

•Release the sleeve.

MANUAL SPINDLE LOCK (FIGURE E)

The manual spindle lock allows you to use the tool as a regular manual screwdriver. You can give an extra twist to firmly tighten a screw or to loosen a very tight screw.

•To activate the spindle lock, turn the collar (3) to show the LOCK symbol.

•To release the spindle lock, turn the collar (3) to show the POWER symbol. NOTE: Do not attempt to operate the tool when the spindle lock is activated.