DC Installation (continued)

Next, connect a minimum 16 AWG red wire from the screw on the side of the shunt positive terminal to the meter positive terminal and connect a black or yellow wire from the shunt negative terminal to the meter negative terminal. There should be a 1 ampere fuse in both sense wires near the shunt terminal. Be certain that on all 4 shunt connections the wire ring terminals sit directly on the brass blocks of the shunt without any washers in between.

Connect a negative return wire from both negative buses on the panel to DC negative.

3. Install battery bank voltage monitor wires

The panel is supplied with a meter and switch to monitor the voltage of three separate sources, usually the batteries. Connect a minimum 16 AWG red wire from each source to be monitored to each of the corresponding input wires of the switch. There should be a 1 ampere fuse in each positive wire near each source.

4. Install branch circuit wires

Determine the proper wire size for each branch circuit using the guidelines in step 4. Verify that the standard 15 amp circuit breakers installed in the panel are large enough for each branch circuit. Remove and replace with a higher amperage any that are undersized. Connect the positive (red) branch circuit wires to the load terminals of each circuit breaker. Connect each negative (black) branch circuit wire to the DC Negative Bus. DO NOT CONFUSE THE DC NEGATIVE BUS WITH THE DC GROUNDING BUS.

5. Installation of Backlight System

Connect the yellow negative wire to the panel negative bus.

To activate the label lights by the boat’s battery switch, connect the red positive wire to the DC panel positive bus.

To activate the label lights by an independent switch or breaker, connect the red positive wire to the load side of the switch or breaker.

6. Optional—install grounding system wire

The grounding wire (bare, green or green with yellow stripe and normally non-current carrying) should not be confused with the negative ground wire (black or yellow and normally current carrying).

In Boatowner’s Illustrated Electrical Handbook, Charlie Wing identifies three purposes of DC Grounding:

1.Holding conductive housings of low voltage (under 50 volts) DC devices at ground potential by providing a low resistance return path for currents accidentally contacting the device cases.

2.Providing a low resistance return path for electrical current, preventing stray currents that may cause corrosion.

3.Grounding metal electrical cases to prevent emission from inside or absorption from outside of radio frequency noise (RFI).

ABYC requires that grounding wires be sized no smaller than one wire size under that required for current carrying conductors supplying the device to which the grounding wire is connected.

7. Optional Branch LEDs

This panel is supplied with LEDs pre-installed in all optional branch positions. For future expansion of the panel remove the positive leg of the LED from the negative bus and connect it to the load side of the corresponding branch circuit breaker.

8. Optional—Upgrading to 24 Volts

Remove and replace the existing 8-16V DC voltmeter with an 18-32V DC voltmeter (PN 8240). Connect the existing meter sense wires to the new meter, Red Positive wire to “+” and Yellow Negative wire to “-”.

Note

This Blue Sea Systems electrical distribution panel is furnished with 15A circuit breakers for DC branch circuits. These ratings will satisfy the vast majority of marine circit protection situations. As shown in the Wire Sizing Chart, even 16 AWG wire, which is the minimum wire size recommended by ABYC, has an allowable amperage greater than 20A.

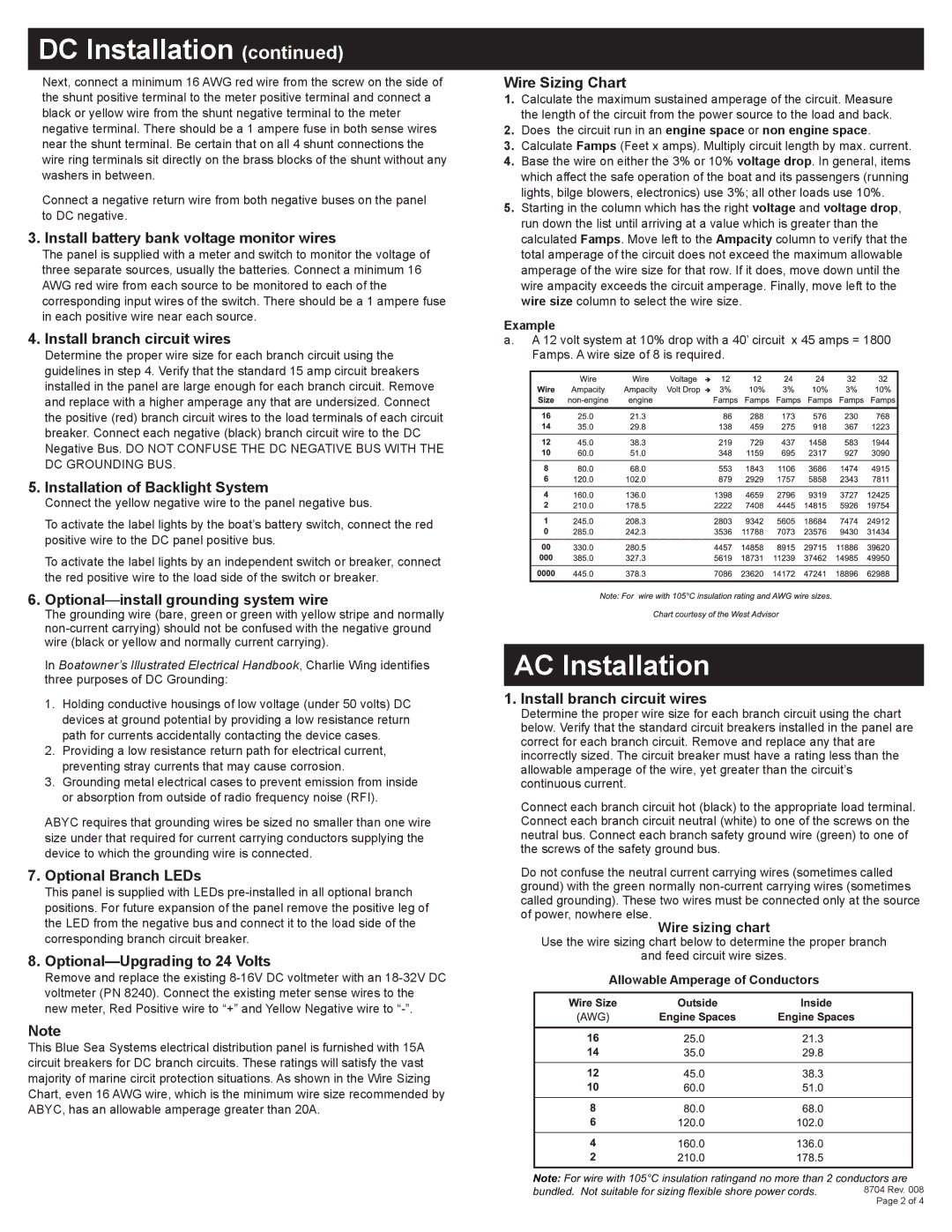

Wire Sizing Chart

1.Calculate the maximum sustained amperage of the circuit. Measure the length of the circuit from the power source to the load and back.

2.Does the circuit run in an engine space or non engine space.

3.Calculate Famps (Feet x amps). Multiply circuit length by max. current.

4.Base the wire on either the 3% or 10% voltage drop. In general, items which affect the safe operation of the boat and its passengers (running lights, bilge blowers, electronics) use 3%; all other loads use 10%.

5.Starting in the column which has the right voltage and voltage drop, run down the list until arriving at a value which is greater than the calculated Famps. Move left to the Ampacity column to verify that the total amperage of the circuit does not exceed the maximum allowable amperage of the wire size for that row. If it does, move down until the wire ampacity exceeds the circuit amperage. Finally, move left to the wire size column to select the wire size.

Example

a.A 12 volt system at 10% drop with a 40’ circuit x 45 amps = 1800 Famps. A wire size of 8 is required.

AC Installation

1. Install branch circuit wires

Determine the proper wire size for each branch circuit using the chart below. Verify that the standard circuit breakers installed in the panel are correct for each branch circuit. Remove and replace any that are incorrectly sized. The circuit breaker must have a rating less than the allowable amperage of the wire, yet greater than the circuit’s continuous current.

Connect each branch circuit hot (black) to the appropriate load terminal. Connect each branch circuit neutral (white) to one of the screws on the neutral bus. Connect each branch safety ground wire (green) to one of the screws of the safety ground bus.

Do not confuse the neutral current carrying wires (sometimes called ground) with the green normally non-current carrying wires (sometimes called grounding). These two wires must be connected only at the source of power, nowhere else.

Wire sizing chart

Use the wire sizing chart below to determine the proper branch

and feed circuit wire sizes.

Allowable Amperage of Conductors