BM 1619929472

Operating Instructions

TRIGGER | selected impact rate and rotating speed | |

To turn the tool “ON” squeeze the trigger | virtually constant between | |

switch. To turn the tool “OFF”, release the | conditions. | |

trigger switch, which is spring loaded and will | INSTALLING ACCESSORIES | |

return to the “OFF” position automatically. | ||

Clean the insert shank end of the accessory | ||

To increase switch life, do not turn switch on | ||

to remove any debris, then lightly grease with | ||

and off while tool is under load. | a light oil or lubricant. |

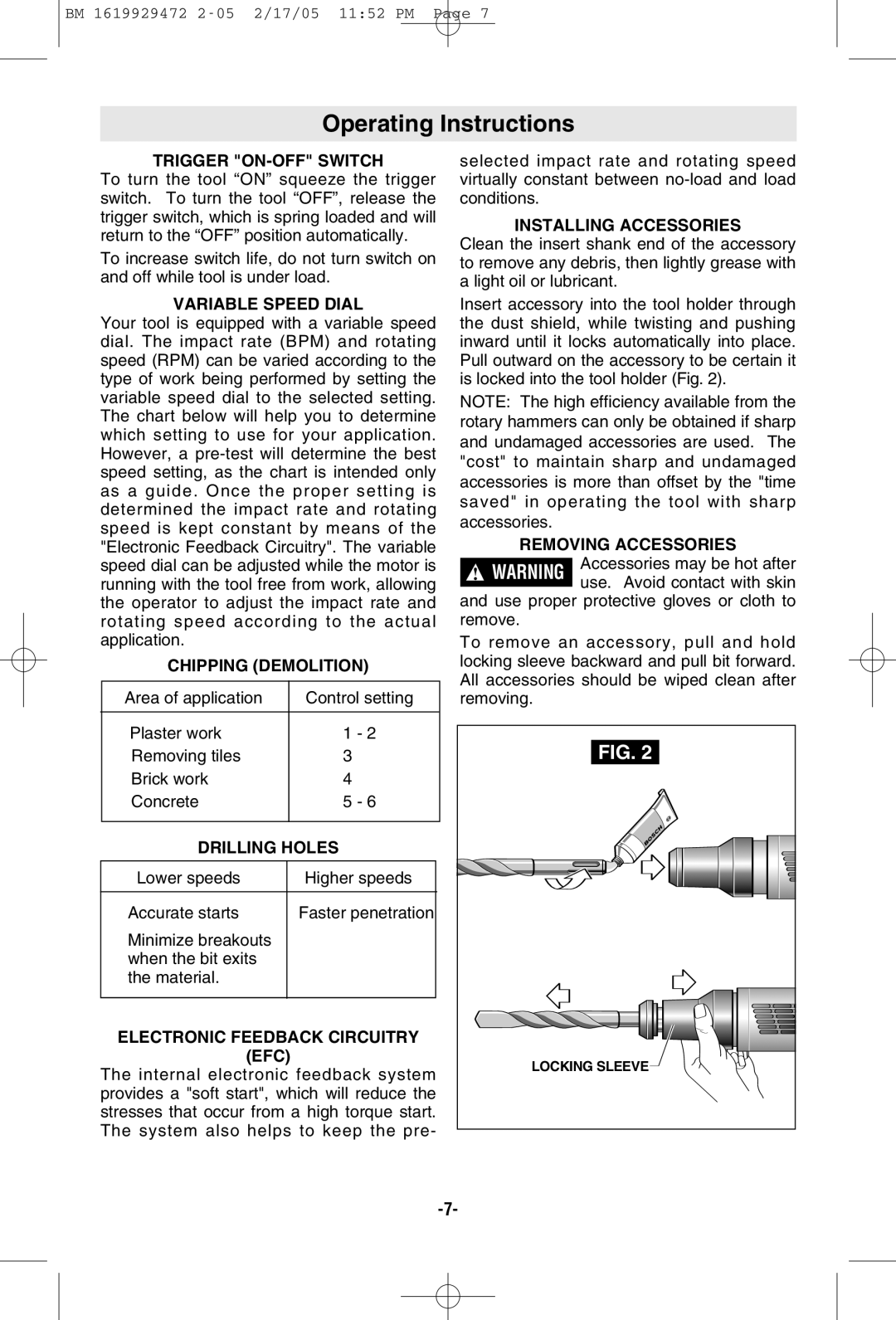

VARIABLE SPEED DIAL | Insert accessory into the tool holder through | |||

Your tool is equipped with a variable speed | the dust shield, while twisting and pushing | |||

dial. The impact rate (BPM) and rotating | inward until it locks automatically into place. | |||

speed (RPM) can be varied according to the | Pull outward on the accessory to be certain it | |||

type of work being performed by setting the | is locked into the tool holder (Fig. 2). | |||

variable speed dial to the selected setting. | NOTE: The high efficiency available from the | |||

The chart below will help you to determine | rotary hammers can only be obtained if sharp | |||

which setting to use for your application. | ||||

and undamaged accessories are used. The | ||||

However, a | ||||

"cost" to maintain sharp and undamaged | ||||

speed setting, as the chart is intended only | ||||

accessories is more than offset by the "time | ||||

as a guide. Once the proper setting is | ||||

saved" in operating the tool with sharp | ||||

determined the impact rate and rotating | ||||

accessories. |

| |||

speed is kept constant by means of the |

| |||

REMOVING ACCESSORIES | ||||

"Electronic Feedback Circuitry". The variable | ||||

speed dial can be adjusted while the motor is | ! WARNING | Accessories may be hot after | ||

running with the tool free from work, allowing |

| use. Avoid contact with skin | ||

the operator to adjust the impact rate and | and use proper protective gloves or cloth to | |||

rotating speed according to the actual | remove. |

| ||

application. |

| To remove an accessory, pull and hold | ||

CHIPPING (DEMOLITION) | locking sleeve backward and pull bit forward. | |||

Area of application | Control setting | All accessories should be wiped clean after | ||

removing. |

| |||

Plaster work | 1 - 2 |

| FIG. 2 | |

Removing tiles | 3 |

| ||

Brick work | 4 |

|

| |

Concrete | 5 - 6 |

|

| |

DRILLING HOLES |

|

| ||

Lower speeds | Higher speeds |

|

| |

Accurate starts | Faster penetration |

|

| |

Minimize breakouts |

|

|

| |

when the bit exits |

|

|

| |

the material. |

|

|

| |

ELECTRONIC FEEDBACK CIRCUITRY |

|

| ||

(EFC) |

| LOCKING SLEEVE | ||

The internal electronic feedback system | ||||

|

| |||

provides a "soft start", which will reduce the |

|

| ||

stresses that occur from a high torque start. |

|

| ||

The system also helps to keep the pre- |

|

| ||

|

|

| ||