020219 specifications

The Briggs & Stratton 020219 is a premium power solution that caters primarily to the needs of outdoor enthusiasts and homeowners alike. Renowned for its reliability, this portable generator stands out due to its outstanding performance and innovative features designed to make it an ideal choice for various applications.At the heart of the Briggs & Stratton 020219 is its robust engine. The generator is equipped with a powerful 208cc four-stroke OHV (Overhead Valve) engine. This engine technology not only enhances the generator's efficiency but also maximizes output performance. The Overhead Valve configuration allows for improved airflow and combustion, resulting in a quieter and cleaner operation compared to conventional designs.

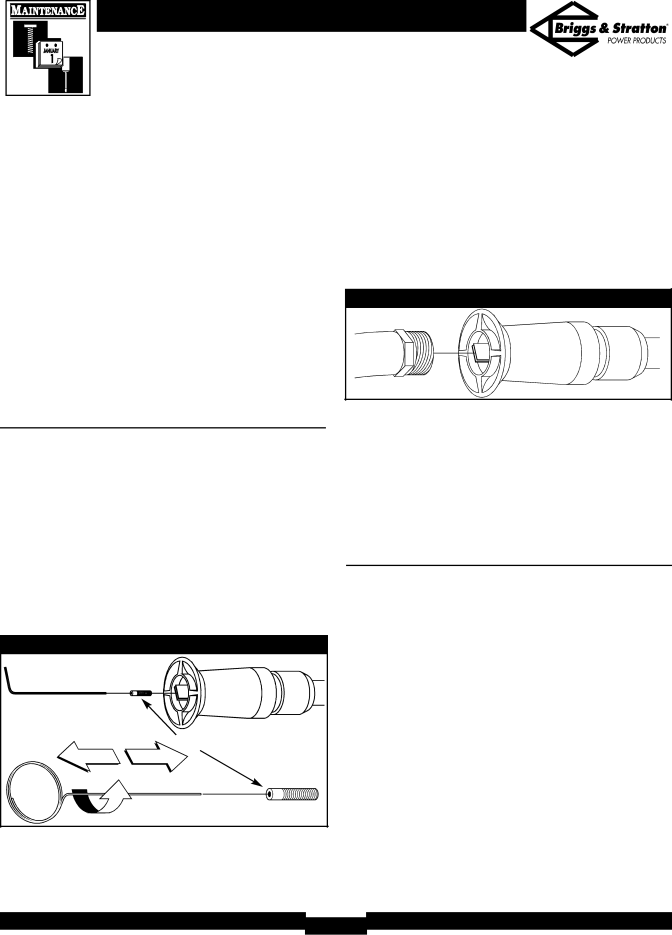

One key characteristic of the Briggs & Stratton 020219 is its ease of use. The generator features a user-friendly control panel that includes multiple outlets, such as 120V household outlets and a 12V DC outlet for charging batteries. This versatility makes it suitable for running household appliances during a power outage, as well as providing energy for tools and recreational equipment during camping trips or outdoor events.

Power output is another standout feature of this generator. The Briggs & Stratton 020219 delivers an impressive runtime, producing a maximum output of 2500 running watts and 3000 starting watts, making it capable of powering multiple devices simultaneously. The generator's built-in fuel tank, with a capacity of 1.5 gallons, provides a substantial runtime of up to 10 hours at a 50% load, allowing users to enjoy extended periods of power without frequent refueling.

To enhance portability, the Briggs & Stratton 020219 comes with ergonomic handles and never-flat wheels, making it easier to transport across various terrains. Additionally, its compact design ensures it fits conveniently in limited storage spaces.

Safety is a top priority for Briggs & Stratton, and this generator includes features such as low-oil shutdown, which automatically cuts off the engine when oil levels drop too low. This technology not only protects the engine but also extends its lifespan, making it a worthwhile investment for users.

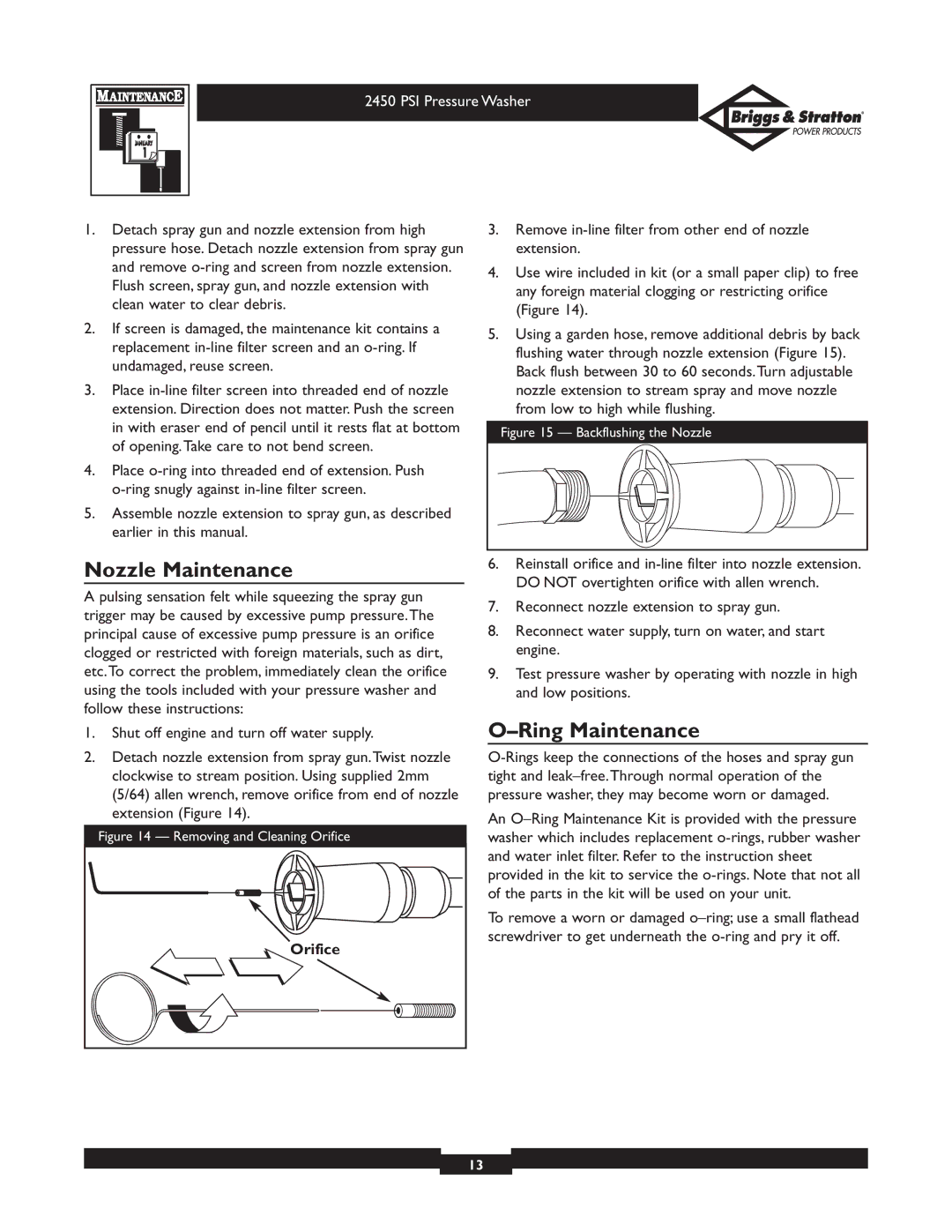

In conclusion, the Briggs & Stratton 020219 is a well-rounded generator that boasts power, efficiency, and portability. With its advanced engine technology, user-friendly features, and safety mechanisms, it serves as a reliable source of electricity for both everyday use and emergency situations. Whether you’re looking to power your home during outages or need a portable solution for your outdoor activities, the Briggs & Stratton 020219 proves to be an excellent companion.