Attractive and accurate sewing finishes for

Increased material penetration force

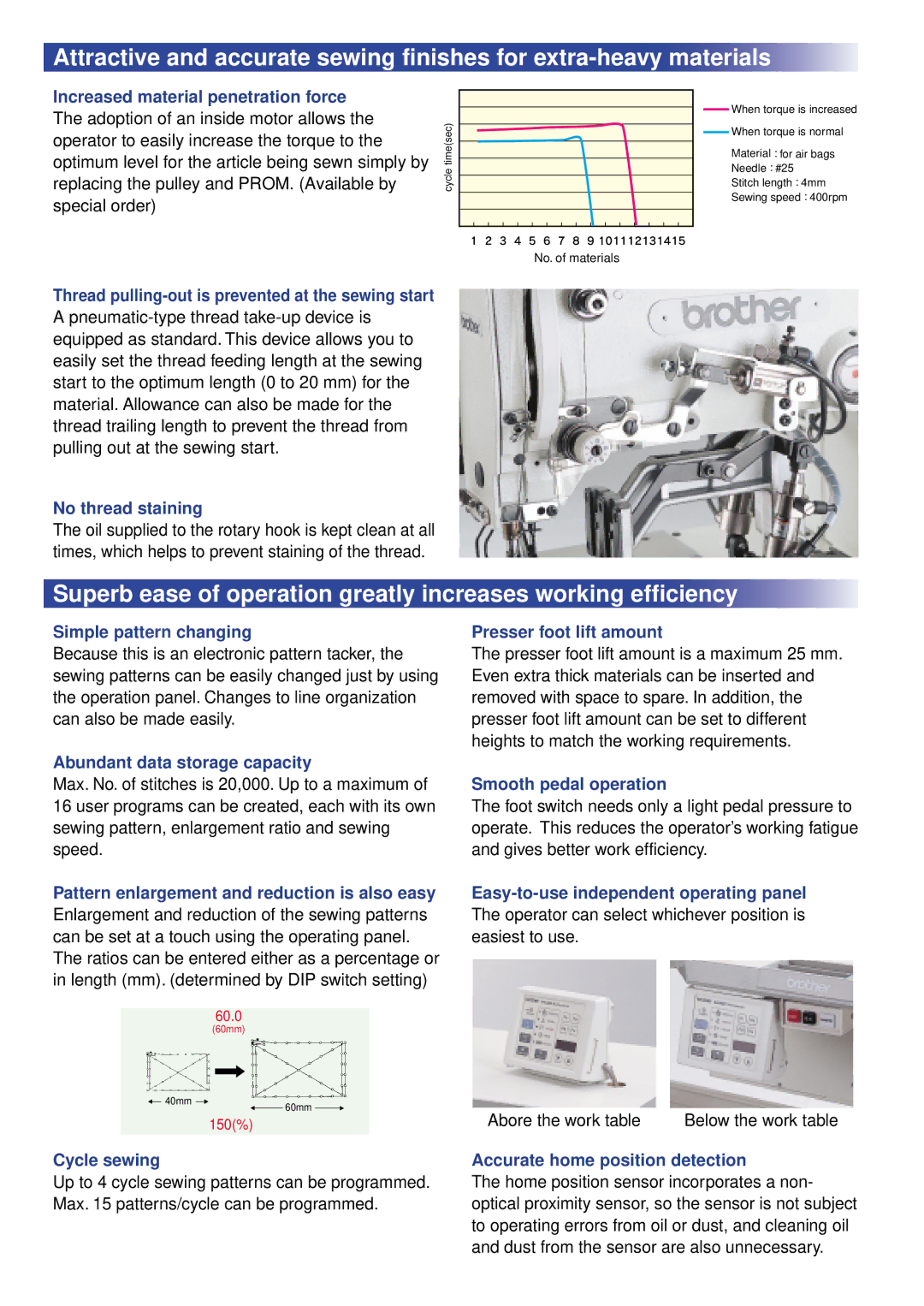

The adoption of an inside motor allows the operator to easily increase the torque to the optimum level for the article being sewn simply by replacing the pulley and PROM. (Available by special order)

cycle time(sec)

When torque is increased

When torque is normal

Material : for air bags

Needle : #25

Stitch length : 4mm

Sewing speed : 400rpm

No. of materials

Thread pulling-out is prevented at the sewing start

A

No thread staining

The oil supplied to the rotary hook is kept clean at all times, which helps to prevent staining of the thread.

Superb ease of operation greatly increases working efficiency

Simple pattern changing

Because this is an electronic pattern tacker, the sewing patterns can be easily changed just by using the operation panel. Changes to line organization can also be made easily.

Abundant data storage capacity

Max. No. of stitches is 20,000. Up to a maximum of 16 user programs can be created, each with its own sewing pattern, enlargement ratio and sewing speed.

Pattern enlargement and reduction is also easy

Enlargement and reduction of the sewing patterns can be set at a touch using the operating panel. The ratios can be entered either as a percentage or in length (mm). (determined by DIP switch setting)

60.0

(60mm)

40mm

![]() 60mm

60mm ![]()

150(%)

Cycle sewing

Presser foot lift amount

The presser foot lift amount is a maximum 25 mm. Even extra thick materials can be inserted and removed with space to spare. In addition, the presser foot lift amount can be set to different heights to match the working requirements.

Smooth pedal operation

The foot switch needs only a light pedal pressure to operate. This reduces the operator’s working fatigue and gives better work efficiency.

Easy-to-use independent operating panel

The operator can select whichever position is easiest to use.

Abore the work table | Below the work table |

Accurate home position detection

Up to 4 cycle sewing patterns can be programmed. Max. 15 patterns/cycle can be programmed.

The home position sensor incorporates a non- optical proximity sensor, so the sensor is not subject to operating errors from oil or dust, and cleaning oil and dust from the sensor are also unnecessary.