Key Product Features

•Harsh environment labeling - laminated labels offer protection from moisture, temperature extremes, certain chemicals, and abrasion.

•High speed, high resolution thermal transfer printing - maximun print speed is 3.15 ips; maximum resolution is 360 x 720 dpi.

•Drop-in label cassettes eliminate the maintenance required with other thermal transfer printers - no transfer ribbons to install or align and no density calibrations required.

•Built-in auto cutter allows labels of various lengths to be printed. Half-cut feature allows multiple labels to be printed on a single strip and peeled off as needed.

•Built-in Ethernet port on the PT-9800PCN allows multiple users to share one printer.

•Host USB port on the PT-9800PCN lets you connect a

USB scanner and print labels from scanned barcode data to downloaded label templates.

•Print from non-Windows applications via the USB, serial and Ethernet interfaces using ESC/P emulation or ASCII data.

•Distributed printing can spread large print jobs over multiple printers.

•Five resident fonts and over 14 linear and two-dimensional barcode symbologies.

•Bundled with P-touch Editor, a powerful software application for designing and printing customized, on-demand labels. You can also use it to connect to a variety of data files.

•BRAdmin Light network management software is included with the PT-9800PCN to make it easier to set up and manage Brother desktop barcode and label printers.

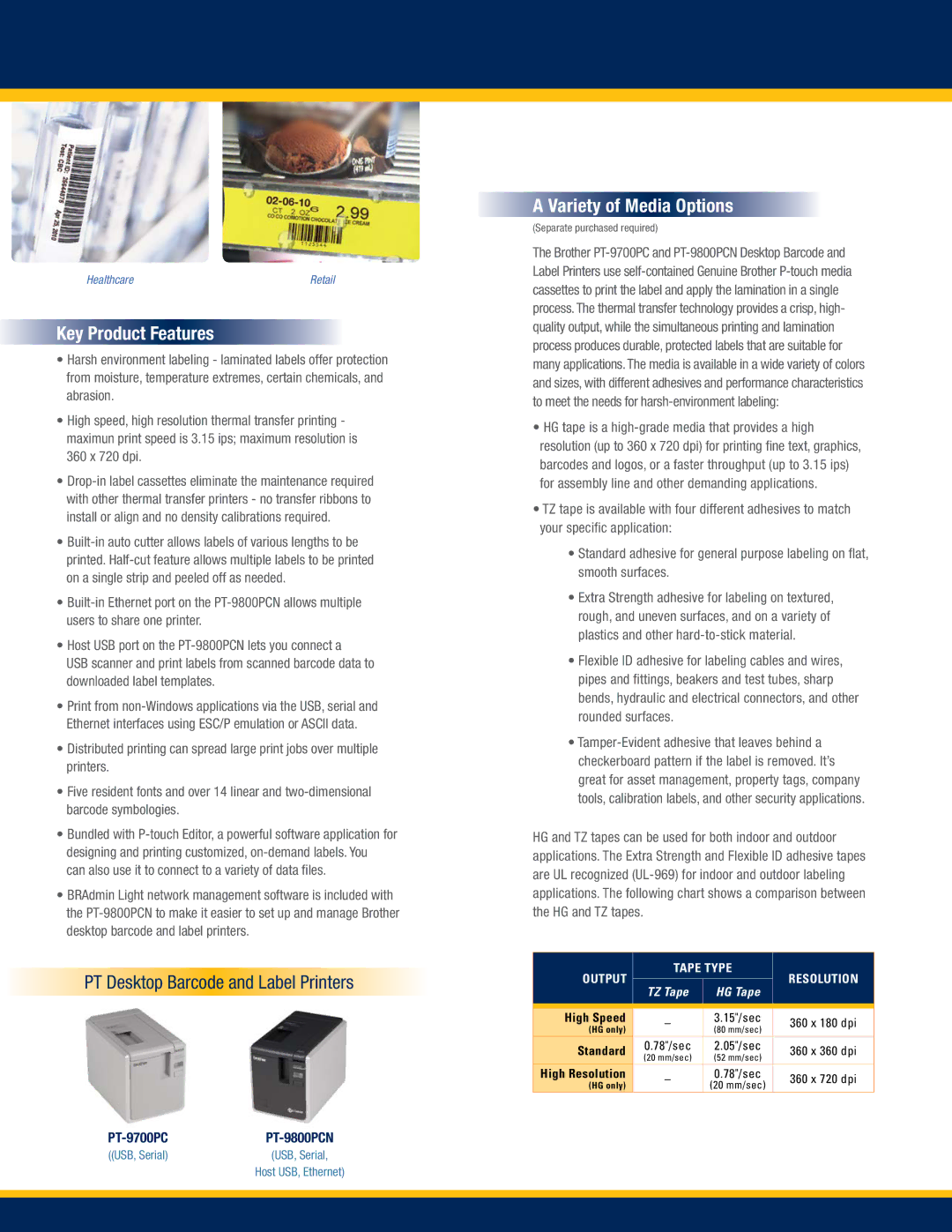

PT Desktop Barcode and Label Printers

PT-9700PCPT-9800PCN

A Variety of Media Options

(Separate purchased required)

The Brother PT-9700PC and PT-9800PCN Desktop Barcode and Label Printers use self-contained Genuine Brother P-touch media cassettes to print the label and apply the lamination in a single process. The thermal transfer technology provides a crisp, high- quality output, while the simultaneous printing and lamination process produces durable, protected labels that are suitable for many applications. The media is available in a wide variety of colors and sizes, with different adhesives and performance characteristics to meet the needs for harsh-environment labeling:

•HG tape is a high-grade media that provides a high resolution (up to 360 x 720 dpi) for printing fine text, graphics, barcodes and logos, or a faster throughput (up to 3.15 ips) for assembly line and other demanding applications.

•TZ tape is available with four different adhesives to match your specific application:

•Standard adhesive for general purpose labeling on flat, smooth surfaces.

•Extra Strength adhesive for labeling on textured, rough, and uneven surfaces, and on a variety of plastics and other hard-to-stick material.

•Flexible ID adhesive for labeling cables and wires, pipes and fittings, beakers and test tubes, sharp bends, hydraulic and electrical connectors, and other rounded surfaces.

•Tamper-Evident adhesive that leaves behind a checkerboard pattern if the label is removed. It’s great for asset management, property tags, company tools, calibration labels, and other security applications.

HG and TZ tapes can be used for both indoor and outdoor applications. The Extra Strength and Flexible ID adhesive tapes are UL recognized (UL-969) for indoor and outdoor labeling applications. The following chart shows a comparison between the HG and TZ tapes.

| OUTPUT | TAPE TYPE | RESOLUTION |

| | |

| TZ Tape | HG Tape |

| | |

| | | | |

| High Speed | – | 3.15"/sec | 360 x 180 dpi |

| (HG only) | (80 mm/sec) |

| | |

| Standard | 0.78"/sec | 2.05"/sec | 360 x 360 dpi |

| (20 mm/sec) | (52 mm/sec) |

| | |

| High Resolution | – | 0.78"/sec | 360 x 720 dpi |

| (HG only) | (20 mm/sec) |

| | |