390BHW4T7, 240BHS4T8 specifications

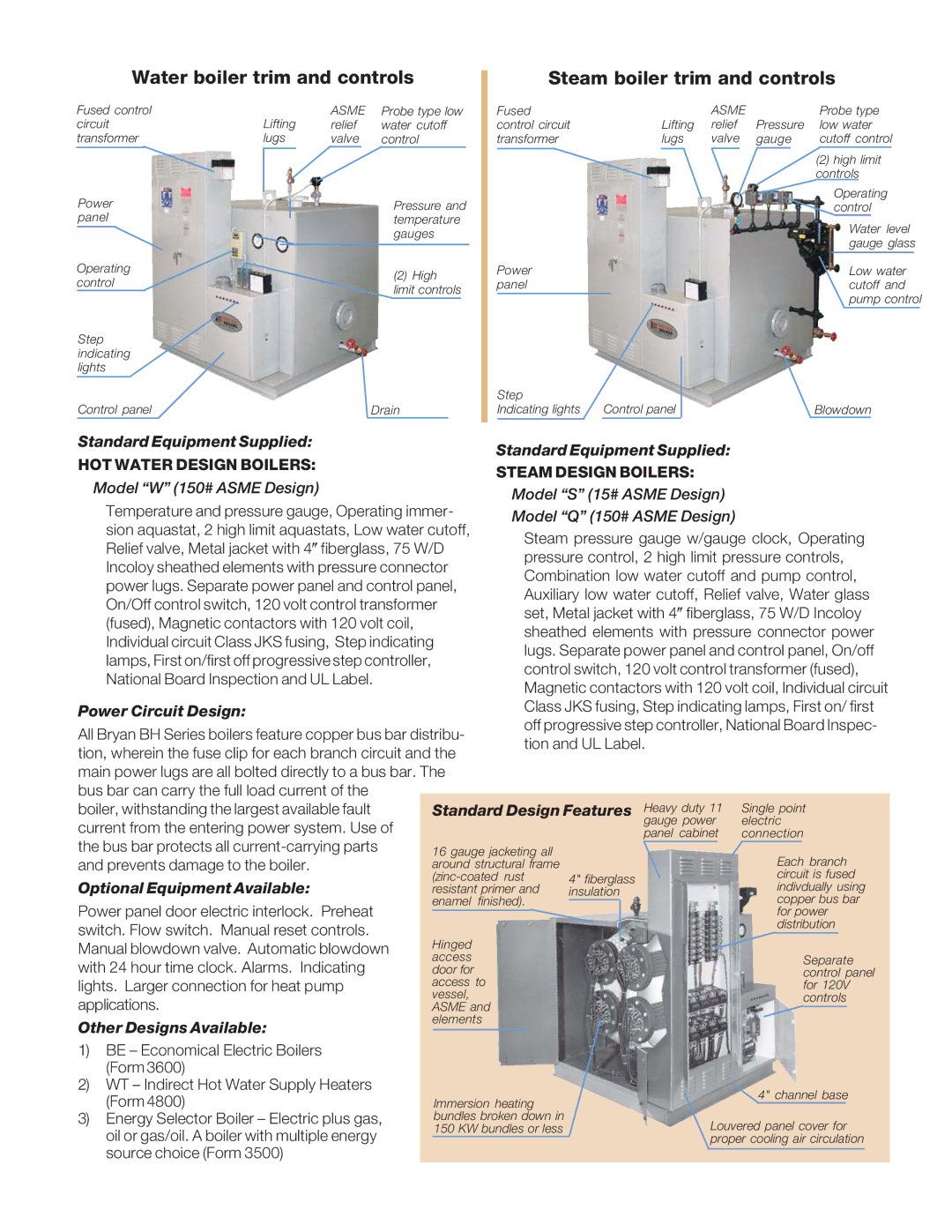

Bryan Boilers has long been a trusted name in the heating industry, and their models 240BHS4T8 and 390BHW4T7 showcase the brand’s commitment to innovative design and exceptional performance. Both boilers represent a remarkable fusion of engineering excellence and advanced technology, making them ideal choices for a range of commercial and industrial applications.The Bryan 240BHS4T8 is a forced-draft, high-efficiency hot water boiler designed to deliver reliable heating with a compact footprint. With a maximum input rating of 240,000 BTU/hr, this model efficiently meets the heating demands of medium-sized operations. One notable feature is its ability to operate on various energy sources, including natural gas, propane, or fuel oil, providing flexibility to users. The boiler also incorporates a state-of-the-art combustion management system that optimizes fuel usage and minimizes emissions, making it an environmentally friendly option.

In terms of technology, the 240BHS4T8 employs Bryan's patented flexible tube design, ensuring excellent heat transfer and efficiency. This design not only enhances performance but also simplifies maintenance procedures, a critical factor for facilities looking to minimize downtime. The boiler is equipped with a fully modulating burner that adjusts fuel flow based on the heating load, resulting in improved fuel efficiency and cost savings over time.

On the other hand, the Bryan 390BHW4T7 offers a greater heating capacity with a maximum input of 390,000 BTU/hr, making it suitable for larger industrial settings. This model features a water wall design that provides increased efficiency and improved heat distribution. The 390BHW4T7 is also designed with built-in safety features, such as low water cut-off devices and high-temperature limit controls to prevent overheating and ensure safe operation.

Both models utilize Bryan's advanced insulation technology, which reduces heat loss and improves overall system efficiency. Moreover, they come with an intuitive digital control panel that offers precise monitoring and control of the heating system, enabling users to effectively manage energy consumption and reduce operational costs.

In summary, the Bryan Boilers 240BHS4T8 and 390BHW4T7 are exemplary models that combine efficiency, reliability, and advanced technology. They cater to diverse heating needs while prioritizing environmental responsibility and safety, solidifying Bryan's reputation as a leader in the boiler industry. Whether for commercial buildings or industrial processes, these boilers deliver performance that users can count on year after year.