Form No. 6410 (5/00)

TM BRYAN STEAM

TM BRYAN STEAM

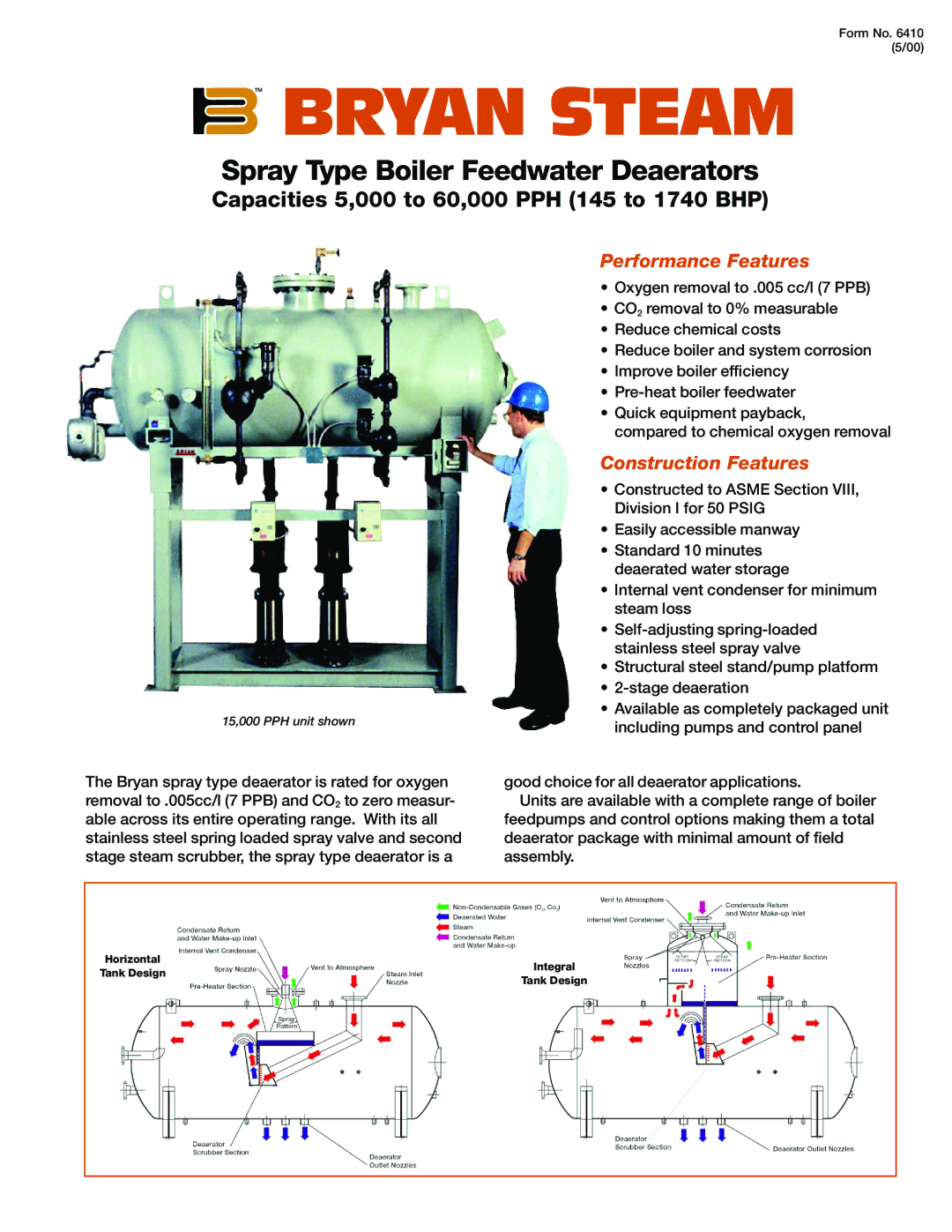

Spray Type Boiler Feedwater Deaerators

Capacities 5,000 to 60,000 PPH (145 to 1740 BHP)

15,000 PPH unit shown

The Bryan spray type deaerator is rated for oxygen removal to .005cc/l (7 PPB) and CO2 to zero measur- able across its entire operating range. With its all stainless steel spring loaded spray valve and second stage steam scrubber, the spray type deaerator is a

Performance Features

•Oxygen removal to .005 cc/l (7 PPB)

•CO2 removal to 0% measurable

•Reduce chemical costs

•Reduce boiler and system corrosion

•Improve boiler efficiency

•

•Quick equipment payback,

compared to chemical oxygen removal

Construction Features

•Constructed to ASME Section VIII, Division I for 50 PSIG

•Easily accessible manway

•Standard 10 minutes deaerated water storage

•Internal vent condenser for minimum steam loss

•

•Structural steel stand/pump platform

•

•Available as completely packaged unit including pumps and control panel

good choice for all deaerator applications.

Units are available with a complete range of boiler feedpumps and control options making them a total deaerator package with minimal amount of field assembly.

Horizontal

Integral

Tank Design

Tank Design