EB-75-S150-FDG, EB-200-W-FDGO specifications

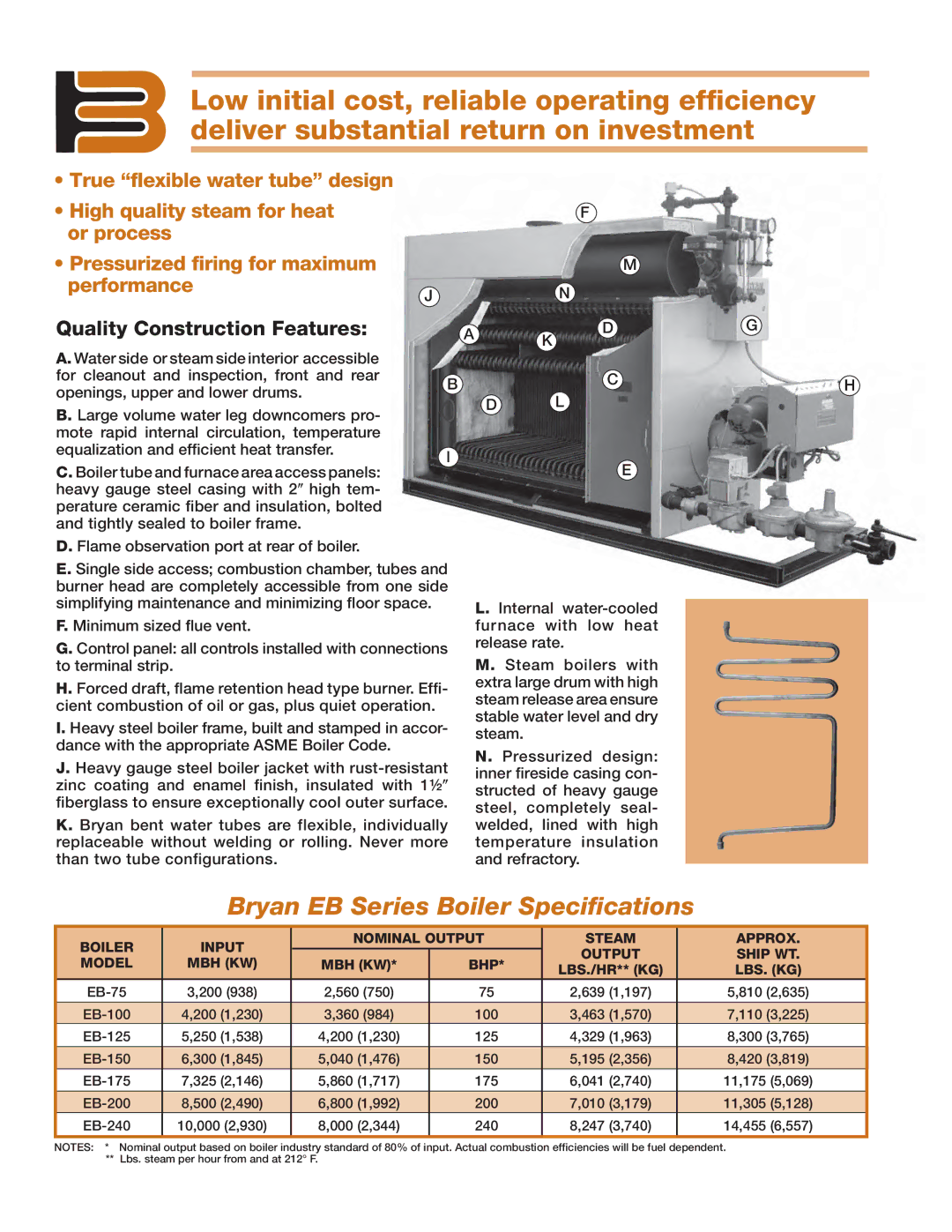

Bryan Boilers is renowned for delivering innovative and efficient boiler solutions, and their EB-200-W-FDGO and EB-75-S150-FDG models exemplify this commitment. Designed for various industrial applications, these boilers are engineered to provide reliable performance, enhanced efficiency, and ease of maintenance.The EB-200-W-FDGO is a water tube, low-pressure steam boiler that boasts a remarkable capacity of 200 horsepower, making it suitable for larger facilities. Its design incorporates a flexible configuration that allows for horizontal or vertical installation, optimizing the available space. This boiler is built with stainless steel components, contributing to its durability and resistance to corrosion.

A standout feature of the EB-200-W-FDGO is its advanced burner technology, which ensures complete combustion and lower emissions. The integrated burner system is designed for natural gas, propane, or other fuels, enabling versatility in fuel selection. Additionally, the boiler features a patented "water wall" design that maximizes the heat transfer surface area, significantly improving thermal efficiency.

Similarly, the EB-75-S150-FDG model is a powerhouse in its own right, offering a capacity of 75 horsepower. This unit is also equipped with advanced construction materials that enhance longevity and performance. The EB-75-S150-FDG features a compact design, making it an ideal choice for facilities with limited space.

Both models are equipped with sophisticated control systems that provide real-time monitoring and adjustments to maintain optimal performance levels. These control systems are user-friendly, allowing for easier operation and maintenance. Furthermore, the boilers are designed to meet stringent environmental regulations, making them an eco-friendly choice for businesses looking to reduce their carbon footprint.

Another notable characteristic of both models is their high efficiency ratings, which translate into significant energy savings over time. They also support crisp steam quality and consistent pressure, which are essential for various processes in industries such as food processing, pharmaceuticals, and textiles.

In conclusion, the Bryan Boilers EB-200-W-FDGO and EB-75-S150-FDG models stand out in the marketplace for their advanced technology, robust design, and versatile applications. These boilers not only provide reliable steam generation but also emphasize efficiency and sustainability, positioning them as smart investments for modern industrial operations.