TABLE 1ÐUPFLOW/HORIZONTAL FILTER SIZE INFOR-

MATION (IN.)

FURNACE | FILTER SIZE² | FILTER | |

CASING WIDTH | Side Return | Bottom Return | TYPE |

|

|

|

|

(1) 16 X 25 X 1* | (1) 14 X 25 X 1 | Cleanable | |

21 | (1) 16 X 25 X 1 | (1) 20 X 25 X 1* | Cleanable |

(2) 16 X 25 X 1* | (1) 24 X 25 X 1 | Cleanable | |

|

|

|

|

*

²Filters may be field modified as required by cutting and folding the frame as indicated on the filter.

a.Turn off electrical supply before removing blower and control access doors.

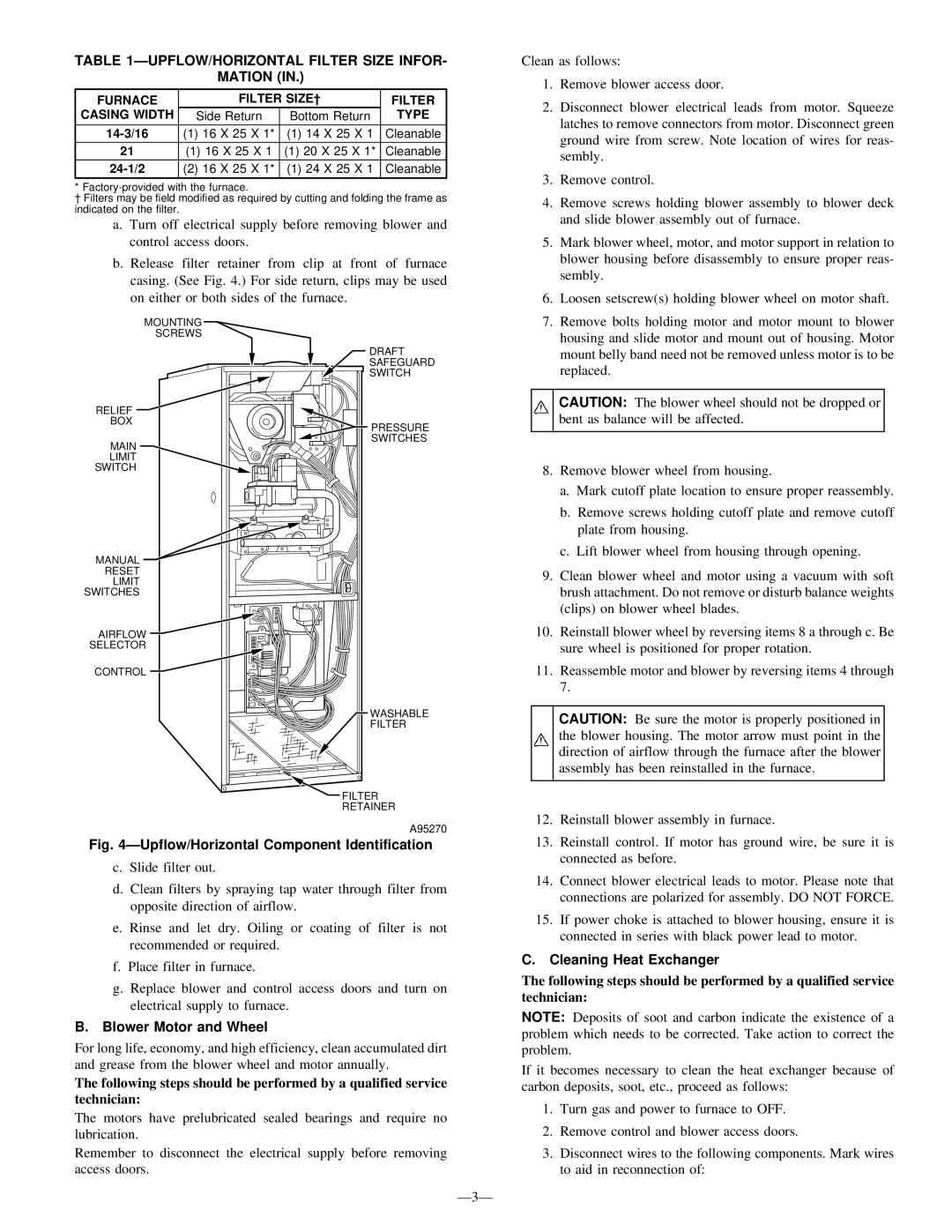

b.Release filter retainer from clip at front of furnace casing. (See Fig. 4.) For side return, clips may be used on either or both sides of the furnace.

MOUNTING

SCREWS

DRAFT

SAFEGUARD

SWITCH

RELIEF |

|

BOX | PRESSURE |

| |

| SWITCHES |

MAIN

LIMIT

SWITCH

MANUAL ![]()

RESET

LIMIT

SWITCHES

AIRFLOW ![]()

![]()

![]()

![]()

SELECTOR

CONTROL ![]()

![]()

WASHABLE

FILTER

![]() FILTER

FILTER

RETAINER

A95270

Fig. 4ÐUpflow/Horizontal Component Identification

c.Slide filter out.

d.Clean filters by spraying tap water through filter from opposite direction of airflow.

e.Rinse and let dry. Oiling or coating of filter is not recommended or required.

f.Place filter in furnace.

g.Replace blower and control access doors and turn on electrical supply to furnace.

B.Blower Motor and Wheel

For long life, economy, and high efficiency, clean accumulated dirt and grease from the blower wheel and motor annually.

The following steps should be performed by a qualified service technician:

The motors have prelubricated sealed bearings and require no lubrication.

Remember to disconnect the electrical supply before removing access doors.

Ð3Ð

Clean as follows:

1.Remove blower access door.

2.Disconnect blower electrical leads from motor. Squeeze latches to remove connectors from motor. Disconnect green ground wire from screw. Note location of wires for reas- sembly.

3.Remove control.

4.Remove screws holding blower assembly to blower deck and slide blower assembly out of furnace.

5.Mark blower wheel, motor, and motor support in relation to blower housing before disassembly to ensure proper reas- sembly.

6.Loosen setscrew(s) holding blower wheel on motor shaft.

7.Remove bolts holding motor and motor mount to blower housing and slide motor and mount out of housing. Motor mount belly band need not be removed unless motor is to be replaced.

CAUTION: The blower wheel should not be dropped or bent as balance will be affected.

8.Remove blower wheel from housing.

a.Mark cutoff plate location to ensure proper reassembly.

b.Remove screws holding cutoff plate and remove cutoff plate from housing.

c.Lift blower wheel from housing through opening.

9.Clean blower wheel and motor using a vacuum with soft brush attachment. Do not remove or disturb balance weights (clips) on blower wheel blades.

10.Reinstall blower wheel by reversing items 8 a through c. Be sure wheel is positioned for proper rotation.

11.Reassemble motor and blower by reversing items 4 through 7.

CAUTION: Be sure the motor is properly positioned in the blower housing. The motor arrow must point in the direction of airflow through the furnace after the blower assembly has been reinstalled in the furnace.

12.Reinstall blower assembly in furnace.

13.Reinstall control. If motor has ground wire, be sure it is connected as before.

14.Connect blower electrical leads to motor. Please note that connections are polarized for assembly. DO NOT FORCE.

15.If power choke is attached to blower housing, ensure it is connected in series with black power lead to motor.

C.Cleaning Heat Exchanger

The following steps should be performed by a qualified service technician:

NOTE: Deposits of soot and carbon indicate the existence of a problem which needs to be corrected. Take action to correct the problem.

If it becomes necessary to clean the heat exchanger because of carbon deposits, soot, etc., proceed as follows:

1.Turn gas and power to furnace to OFF.

2.Remove control and blower access doors.

3.Disconnect wires to the following components. Mark wires to aid in reconnection of: